Laminating Water Chiller

|

Contents Table

6.1 Compressor

6.2 Evaporator

6.3 Water Pump

6.4 Condenser

6.5 Controller Panel

|

Laminating machines generate incredible amounts of heat to seal plastic materials around printed documents and other products. In an industrial laminate environment, this heat needs to dissipate somewhere. Without chilled water running through it to keep it at the required temperature, the laminator won‘t work properly. Our Laminating chillers can provide high quality chilled water at reasonable prices. A variety of different installation configurations are available to meet a variety of your needs. Glycol chillers, industrial chillers, packaged chillers, split chillers, portable chillers, and custom chillers available.

1.What Is Lamination ?

Lamination is the process of permanently bonding two or more layers of materials together to enhance their properties or create a composite material with improved properties. This is usually achieved through heat, pressure or adhesives.

Here are some common lamination types and their applications:

Film lamination:

In the film lamination process, heat and pressure are used to apply a thin layer of plastic film, such as polyethylene or polypropylene, to a surface. This is often used in packaging to provide protection, improve appearance, and add strength.

For example, laminating films to paper can create products such as glossy magazine covers or laminated ID cards.

Paper texture:

This involves coating another surface, such as cardboard or wood, with a layer of paper, usually coated with an adhesive. It is used to improve the appearance and durability of printed materials such as posters, labels and book covers.

Fabric texture:

Fabric lamination involves bonding one layer of fabric to another material, usually using adhesives and heat. This can create textiles with enhanced properties, such as waterproofing, insulation or flame retardancy.

Wood texture:

In wood processing, lamination involves gluing together multiple layers of wood to create a stronger, more stable composite material. This technique is commonly used in the manufacture of plywood and engineered wood products.

Fiberglass Lamination:

This process involves applying a fiberglass fabric or underlayment to the surface using resin. The resulting composites are lightweight and strong and are commonly used in shipbuilding, automotive parts and aerospace applications.

Lamination serves a variety of purposes, including improving durability, providing protection from environmental factors, enhancing appearance, adding strength or rigidity, and providing special properties such as water resistance or fire resistance. The choice of materials and lamination technology depends on the intended application and the specific properties required of the final product.

2.What is A Laminating Chiller?

A Laminating chiller is a specialized cooling device used in Laminating facilities. Its primary purpose is to control and maintain the temperature of the solvent used in the Laminating process.The use of a Laminating chiller is especially important when a solvent like perchloroethylene (perc) is employed, as it can be sensitive to temperature variations. By maintaining a consistent and controlled temperature, Laminating chillers can ensure that the cleaning process is effective and safe

4.What’s the Difference Between Air-cooled & Water-cooled Laminating Chillers?

There are two types of Laminating chiller: one is air-cooled Laminating chiller ,the other is water-cooled Laminating chiller ;

Water-cooled Laminating chillers use water from an external water cooling tower to dissipate heat from the brewing processes. These systems are longer lifespan, Relatively quiet, and more consistent cooling performance than the air-cooled Laminating chiller.

Laminating Scroll Chiller Laminating Screw Chiller

▪1/2 HP-60HP(2KW-170KW) Above 60HP(Above 170KW)

▪ Danfoss/Panasonic Scroll Compressor Hanbell/Bitzer Screw compressor

▪Built with water tank and water pump Without water tank and water pump

Air-cooled Laminating Scroll Chiller Air-cooled Laminating Screw Chiller

6.What Are The Main Components of Laminating Chillers?

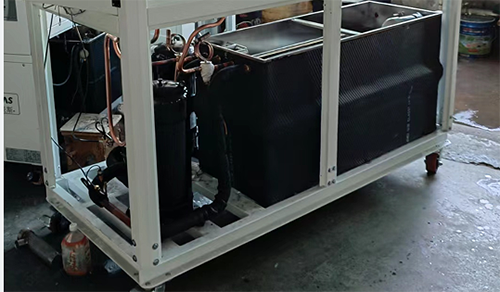

Above 60HP Laminating chiller,which is with Hanbell or Bitzer screw compressor;

Panasonic Compressor

Danfoss Compressor

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

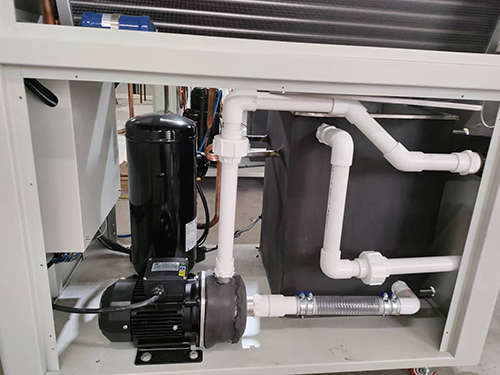

6.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

Laminating Chiller is used with 304 Stainless Steel Water pump.

Water Pump

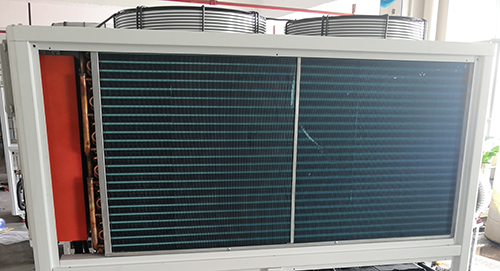

6.4 Condenser

The condenser for air-cooled Laminating cooler is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser for air -cooled Laminating chiller

The condenser for water-cooled Laminating cooler is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser for water-cooled Laminating chiller

6.5 Controller Panel

Water chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

8.How to Choose Right Laminating Chiller for Your Laminating Process?

There are two types of chiller :Air Cooled Laminating Chiller and Water Cooled Laminating Chiller.

But Most customers use air cooled Laminatingchiller ,which is more easily install and save space.

9.Get a Quote on Industrial Laminating Chillers Now

As a leading industrial chiller manufacturer,we engineer and produce high-quality process chillers compatible with a broad range of industrial processes.

Depending on your needs, we also offer custom chillers to ensure that each client receives the industrial chiller best suited to their unique process.

Request a quote now on our Laminatingwater chillers or learn about the other air-cooled chillers and water-cooled chillers.

.jpg)