MRI is the abbreviation for magnetic resonance imaging. This is an imaging technology that uses strong magnetic fields and radio waves to create detailed images of organs and tissues in the body.

During an MRI scan, the patient lies inside a giant cylindrical machine. A powerful magnetic field aligns the magnetization direction of hydrogen atoms in the body, and a radiofrequency field is applied to systematically change this alignment, causing the hydrogen atoms to produce a rotating magnetic field that is detected by the scanner. This signal can be manipulated with additional magnetic fields to build up enough information to construct an image of the body.

An MRI scan can be used to examine almost any part of the body, including the brain, spinal cord, bones, joints, breasts, heart and blood vessels, as well as internal organs such as the liver and lungs. They can be used to diagnose various medical conditions, guide certain treatment procedures, and monitor the progression of disease.

2.What is An MRI Chiller?

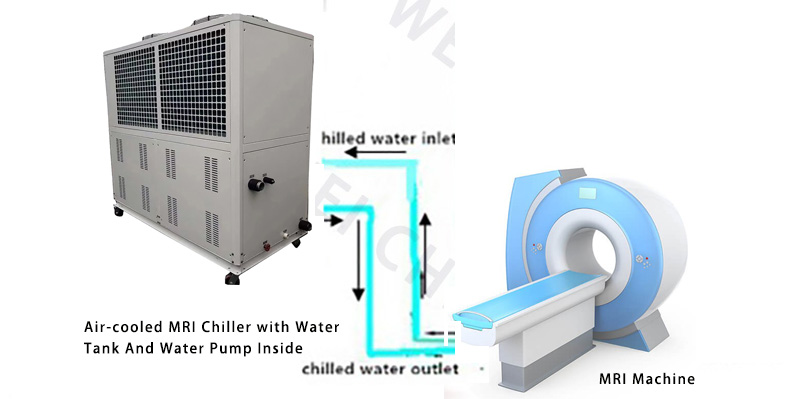

An MRI chiller is a medical device used to keep MRI machines cool. A chiller circulates water through coils inside the MRI machine to maintain a constant temperature. Without a MRI chiller, the MRI machine will heat up and possibly be damaged.

The MRI cooler is usually located in a room adjacent to the MRI machine room. They are typically large industrial machines that require a lot of space.

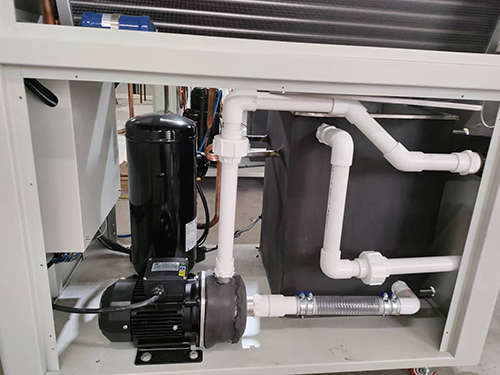

15 Ton Air Cooled MRI Chiller

15 Ton Air Cooled MRI Chiller

3.Why MRI Machines Need MRI Chiller System?

MRI machines use powerful magnets to produce images of the human body. These magnets are so powerful that they can cause objects to become magnetized, which if not managed properly can damage the machine or even pose a risk to patient safety. Therefore, MRI machines must be kept in very cold environments.

The main component in an MRI machine that requires cooling is the magnet.The magnets in most MRI machines are superconducting magnets and are maintained at a temperature of minus 270 degrees Celsius. This is because the colder the environment, the less likely it is that any magnetic objects will be affected by the MRI machine.

However, the process of keeping the magnets warm generates a lot of heat. Failure to effectively remove this heat can cause the magnet to lose its superconductivity ,which can be dangerous and expensive.The MRI chiller system helps maintain the temperature of the MRI machine and prevents it from getting too hot. If the temperature of the MRI machine is too high, the quality of the imaging will be affected. Additionally, if the machine gets too hot, it can be dangerous for the patient using it.

Therefore, the chiller plays a vital role in the safe and efficient operation of the MRI machine.

4.How Does An MRI Chiller Work?

An MRI machine chiller works by circulating refrigerant around a series of coils. As the refrigerant circulates, it absorbs heat from the MRI scanner. This process helps keep the scanner cool and prevents it from overheating. The cold refrigerant then passes through the condenser, which turns it back into a liquid. The liquid refrigerant then circulates back to the MRI scanner, starting the process all over again.

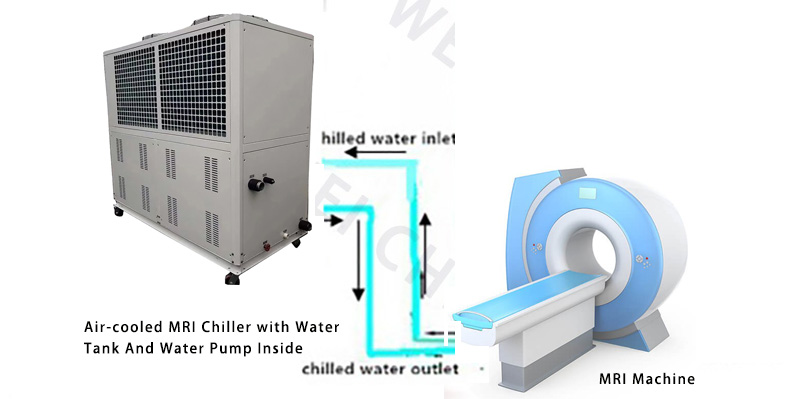

Installation I

Installation I

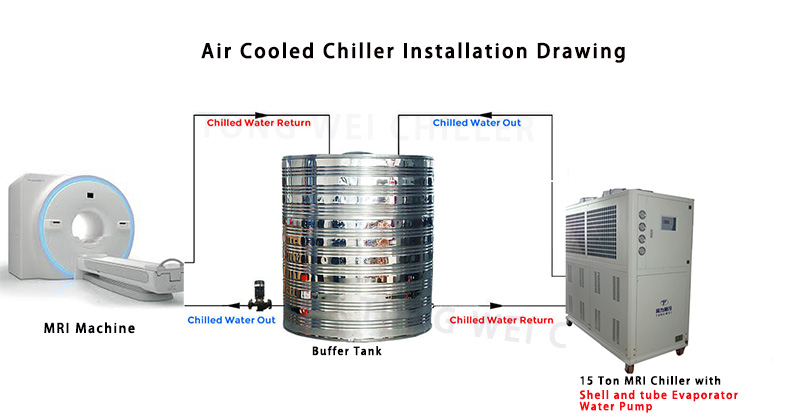

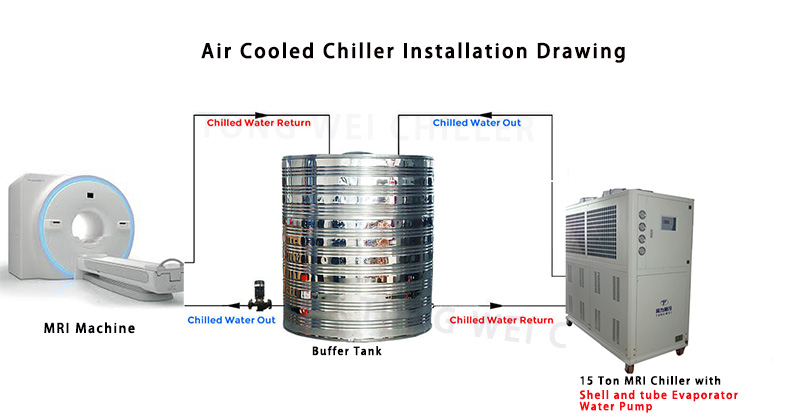

Installation II

Installation II

5.What’s the Difference Between Air-cooled & Water-cooled MRI Chillers?

There are two types of MRI chiller: one is air-cooled MRI chiller ,the other is water-cooled MRI chiller ;

Air-cooled MRI chillers use ambient air to dissipate heat from the brewing processes. They are energy-efficient, space-saving, and less maintenance that helps save money.

Water-cooled MRI chillers use water from an external water cooling tower to dissipate heat from the brewing processes. These systems are longer lifespan, Relatively quiet, and more consistent cooling performance than the air-cooled MRI chiller.

Air-cooled MRI Scroll Chiller Water-cooled MRI Scroll Chiller

Should you choose an air-cooled or water-cooled MRI chiller? Contact Us for help determining the best solution for you.

6.What is the Difference Between MRI Scroll Chiller and MRI Screw Chiller?

MRI Scroll Chiller MRI Screw Chiller

▪1/2 HP-60HP(2KW-170KW) Above 60HP(Above 170KW)

▪ Danfoss/Panasonic Scroll Compressor Hanbell/Bitzer Screw compressor

▪Built with water tank and water pump Without water tank and water pump

Air-cooled MRI Scroll Chiller Air-cooled MRI ScrewChiller

Water-cooled MRI Scroll Chiller Water-cooled MRI Screw Chiller

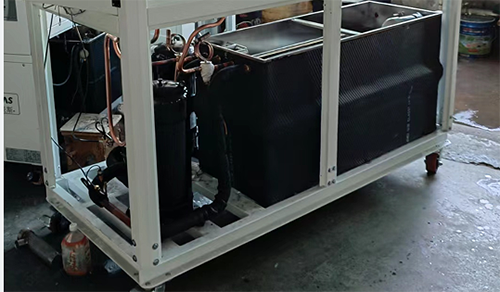

7.What Are The Main Components of MRI Chillers?

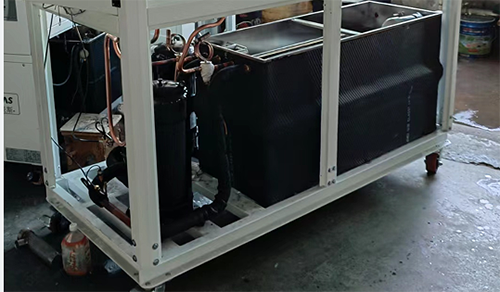

7.1 Compressor

The compressor is the key mover in water chiller because it produces pressure variations to stir the refrigerant around.

From 1/2HP(1/2 Ton) to 60HP(5oTon) waterjet cutting chiller , which is with Panasonic or Danfoss brand Scroll compressor ,

Panasonic Compressor

Panasonic Compressor

Danfoss Compressor

7.2 Evaporator

The evaporator is a crucial component of air-cooled water chiller, as it is responsible for extracting heat from the liquid being cooled,it is located between the compressor and the expansion valve. There are three types of evaporators : coil in water tank evaporator , shell and tube evaporator, 304SS stainless steel plate type evaporator.

Coil in SS Water Tank Evaporator

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

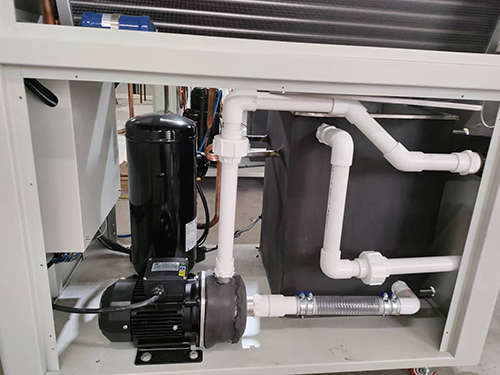

7.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

MRI Chiller is used with 304 Stainless Steel Water pump.

Water Pump

7.4 Condenser

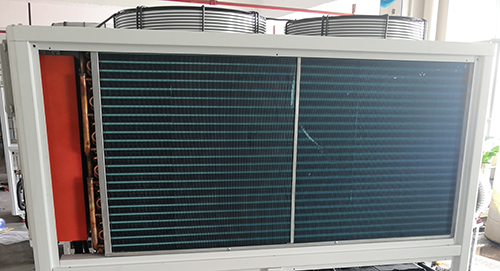

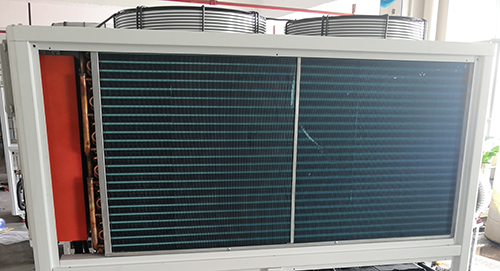

The condenser for air-cooled MRI cooler is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser for air -cooled MRI chiller

The condenser for water-cooled MRI cooler is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser for water-cooled MRI chiller

7.5 Controller Panel

Water chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

8 What are the Key Features of a MRI Chiller?

▪ Energy-efficient Panasonic/Danfoss compressor

▪ 304 Stainless steel water pump

▪ Chilled 0utlet water temperature control 7℃ to 25℃

▪ Precise temperature controller

▪ Environment-friendly refrigerant R407c/r410a

▪ PID temperature controller

▪ Easy installation ,operation and low cost of maintenance

▪ 304 Stainless Steel Coil in SS water tank as evaporator

9.How to Choose Right MRI Chiller for Your MRI Process?

How to calculate right cooling capacity for your MRI chillers?

One of the most frequently ask about how we can know the cooling capacity for chillers.

The range of a chiller at which it can discharge heat from a heated fluid is called cooling capacity.

The cooling capacity of a laser Chiller ranges from 1/2KW to 100KW.

Let’s see the below formula.

Cooling Capacity(kw)= Flow Rate(m3/h)*Temp Change(T1-T2)/0.86

Heat Load= C(specific heat)* M(quality output per hour )*Temp Change(T1-T2)

Oversize the chiller by 20% Ideal Size in KW = KW x 1.2

Noted : T1:Incoming Water Temperature (℃) T2:Required Chilled Water Temperature(℃)

For example, what size of chiller is required to cool 5m³ water from 25°c to 15 °c in 1 hour?

Temperature Differential = 25℃-15℃=10℃

Water Flow Rate = 5 m³/hour

Cooling Capacity in KW = 5 x 10 ÷ 0.86 = 58,14 KW

Oversize the chiller = 58.14 x 1.2 = 69.76 KW

69.96kw cooling capacity for chiller is required.

Types of MRI chiller system?

There are two types of chiller :Air Cooled MRI Chiller and Water Cooled MRI Chiller.

Water cooled chiller needs a separated water cooling tower and water cooling pump ,if you don‘t have exsiting water cooling tower,we suggest you use air cooled chiller; But if your ambiemt temperature is very high above 55℃ ,we suggest you use water cooled chiller , as it is easier to dissipate heat for water cooled chiller with water cooling tower.

But Most customers use air cooled MRI chiller ,which is more easily install and save space.

Whether chillers need built-in Tank or not?

In a chiller system, a tank is usually equipped to buffer the thermal load of the chiller.

But should we choose a built-in type of tank or an external type of tank?

A chiller with a built-in tank is easier to install and can be used simply by connecting a water pipe to your application.

But it has a limited capacity and is not suitable for applications with larger chilled water demands.External tank’s capacity can be customized according to specific needs.

It can buffer a larger heat load, store more chilled water, but the installation will be more troublesome.

If you don‘t have external water tank ,we suggest our chiller built-with water tank ,which is easy for you to install.

Cooling capacity unit conversion?

1 KW=860 kcal/h ;

1 TON=3.517 KW;

1 KW=3412 Btu/h;

10.Get a Quote on Industrial MRI Chillers Now