Brewery chillers

Tongwei Chiller is specialized in manufacturing and supplying industrial-grade process chiller in brewery industry .We offer packaged chillers, Portable Chillers, Glycol Chillers and other water cooling systems that keep the brewing processes cool. Now, we have installed many chillers in breweries where our experience and expertise are meeting the needs of Brewers around the world. Beginning with the construction of package units that were not commercially available, our current Brewery Chillers have been continually refined from their original design by incorporating the best of our client’s ideas and suggestions into our own standard chillers.

Brewery Process

▪ Brite tanks cooling

▪ Fermenters cooling

▪Two-stage heat exchangers cooling

▪ Cold chilling of juice and beer

▪ Nano Brewery

▪ Brew House Chiller

▪ Prepackaging brewery distillery

▪ Wineries

▪ Cider mills brewery

▪ Crash cooling, etc.

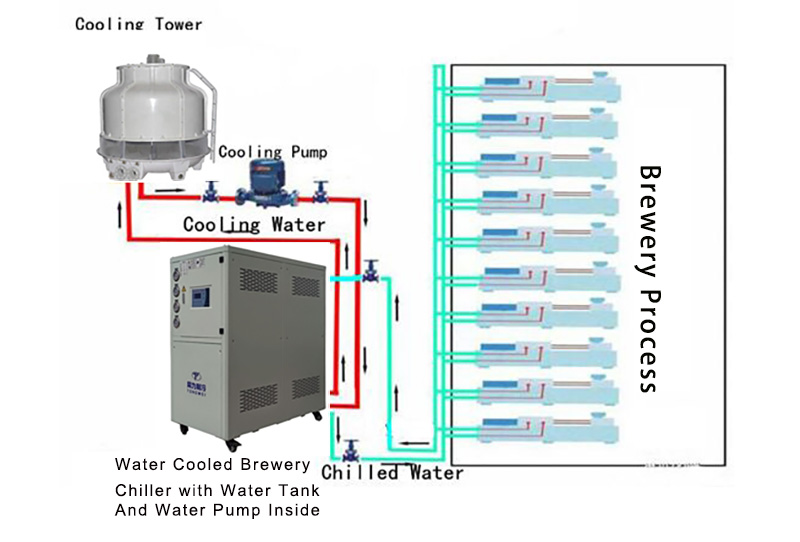

Water-cooled brewery chillers use water from an external water cooling tower to dissipate heat from the brewing processes. These systems are longer lifespan, Relatively quiet, and more consistent cooling performance than the air-cooled brewery chiller.

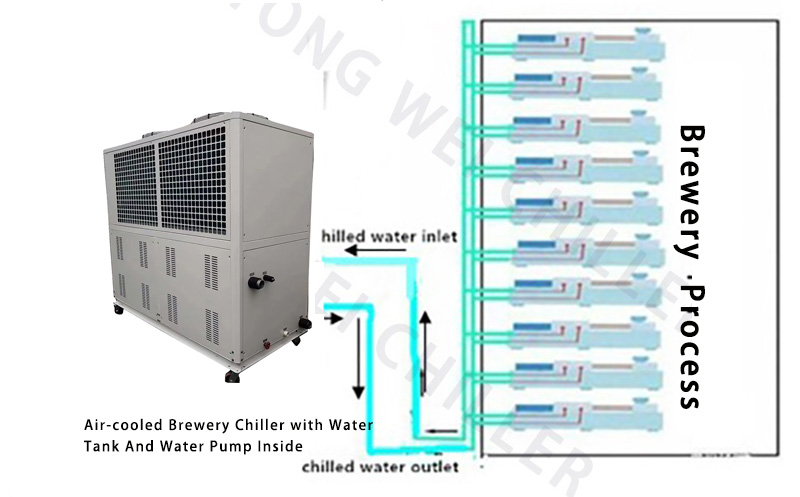

Air-cooled Brewery Chiller Installation Drawing

Water-cooled Brewery Chiller Installation Drawing

5.What Are the Differences Between Brewery Scroll Chiller and Brewery Screw Chiller?

Brewery Scroll Chiller Brewery Screw Chiller

▪1/2 HP-60HP (2KW-170kw) Above 60HP(Above 170KW)

▪ Danfoss/Panasonic Scroll Compressor Hanbell/Bitzer Screw compressor

▪Built with water tank and water pump Without water tank and water pump

Air-cooled Brewery Scroll Chiller Air-cooled Brewery Screw Chiller

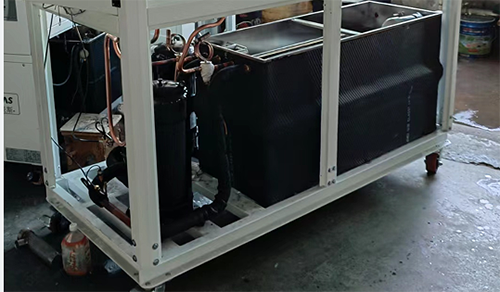

6.What Are The Main Components of Brewery Chillers?

Above 80HP(70 Ton) brewery chiller , which is with Hanbell or Bitzer brand Screw compressor ,

These brand compressors are with high refrigeration efficiency,low noise ,energy saving,environmental protection and durability,safety and stability.

Panasonic Compressor

Danfoss Compressor

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

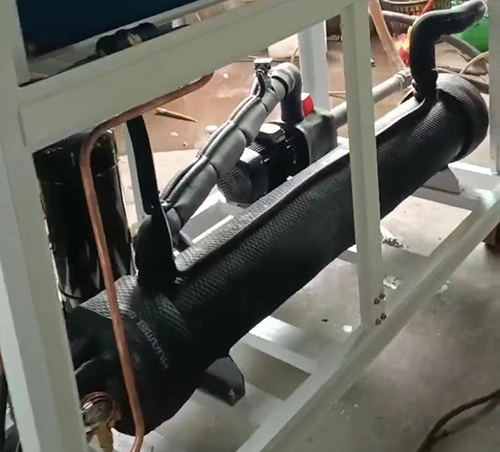

Shell and Tube Evaporator

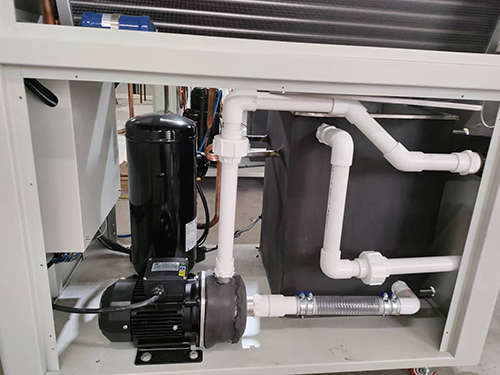

6.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

Water Pump

High Pressure Water Pump

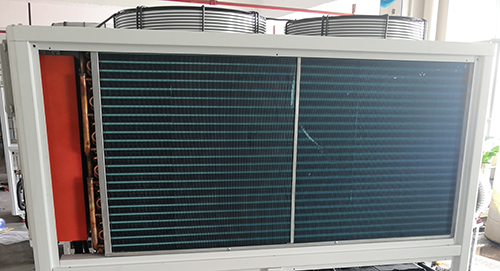

6.4 Condenser

The condenser for air-cooled brewery chiller is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser for air -cooled brewery chiller

The condenser for water-cooled brewery chiller is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser for water-cooled brewery chiller

6.5 Controller Panel

Brewery chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

▪ Determine the coolant type, inlet and outlet water temperature, and flow rate that a Brewery Chiller must provide your brewery application.

▪ The brewery chiller you want install indoor or outdoor?

▪ Use and inspect performance curves and pump performance curves for the selection of the Brewery Chiller model for your application.

You need air -cooled type brewery chiller or water-cooled type brewery chiller? If you need water-cooled type brewery chiller,which need connect water cooling tower and water cooling pump.

▪ Pull-down/crashing loads

▪ Active fermentation heat load

▪ Wort heat exchanger secondary heat load

▪ Brite tank holding load

▪Temperature differential.

▪ Compensation factors for heat loss in pipes, pumps, and other equipment

As a leading industrial chiller manufacturer,we engineer and produce high-quality process chillers compatible with a broad range of industrial processes.

Depending on your needs, we also offer custom chillers to ensure that each client receives the industrial chiller best suited to their unique process.

Request a quote now on our brewery chillers or learn about the other air-cooled chillers and water-cooled chillers.

.jpg)