1.What is Fermentation Chillers ?

A fermentation chiller is a cooling machine used to cool a fermentation chamber by releasing heat from the fermentation chamber to a water or air cooling system around the condenser.

Fermentation chillers are available with large capacity and variety, especially water-cooled and air-cooled fermentation chillers which can precisely regulate the temperature of the fermentation process.

We are specialized in manufacturing and supplying industrial-grade process chiller in fermentation cooling .We offer packaged chillers, Portable Chillers, Glycol Fermentation Chillersand other water cooling systems that keep the fermentation processes cool. Beginning with the construction of package units that were not commercially available, our current fermentation Chillers have been continually refined from their original design by incorporating the best of our client’s ideas and suggestions into our own standard chillers.>

We can also custom design and manufacture glycol fermentation chillers to meet your specific needs.If you need a fermentation chiller for a different fermentation process cooling? Contact Us– we’re here to help.

2.What are the Applications of Fermentation Chillers

In the fermentation tank jacket process cooling, you will need to use a Fermentation Chiller to maintain the fermentation temperatures you want.

Here are some of the common applications of a Fermentation Chiller in temperature regulation.

▪ Wine Production Industry

▪ Brewery Production Industry

▪ Juice Production Industry

▪ Alcohol production Industry

▪ Fermented food production industry

Regardless of the scale of the operation, the process of making wine, lager, stout, ale, and IPA requires careful regulation of brewing and fermentation environments. The fermentation stage is especially critical to the outcome of the brew, as any unfavorable temperature level (too high or too low) can spoil a batch of beer, altering the final flavor and mouthfeel and Aroma, leading to poor brewing.

To prevent the fermentation mixture from being exposed to undesired temperature levels, winemakers often attempt to actively cool the process. For breweries producing beverages on a large scale, the most effective way to ensure optimal temperature regulation is to use a fermentation cooling jacket in combination with a brewery chillers or distillery glycol chillers.

3.What Is a Fermentation Cooling Jacket?

The fermentation/wine tank cooling jacket is a temperature regulation technology that cools the brewing from the outside. A standard tank cooling jacket is made of a flexible material with cavities through which coolant (usually a mixture of glycol and water) can flow. Heat is absorbed in the glycol jacket when the drum is on a winery or brewery vat.

4.How Does a Fermentation Tank Cooling Jacket Work?

The fermenter cooling jacket consists of a flexible material within which the coolant channels run. When wrapped around a brewing barrel, the coolant flows within the channels of the jacket, absorbing heat from the brewing liquid through a simple heat exchange process.

Some of the advantages of using tank cooling jackets include:

▪ Easily adjustable temperature levels allow for more even cooling and fermentation

▪ Prevent accidental contamination as vat integrity cannot be tampered with

▪ Ease of installation and maintenance

Fermenter cooling jackets are essential for the entire brewery An integral part of the chiller setup. Industrial chillers help re-cool the heated coolant returning from the storage tank cooling jacket in preparation for recirculation. Chillers keep the coolant at the optimum wine or beer fermentation temperature.

Temperature regulation can be achieved by manually closing valves or an automated process using direct heat feedback from the circulating coolant. All cold pellet coolers use the latter method.

5.What Is the Ideal Coolant to Use in a Wine Cooling Jacket?

In most cases, a mixture of glycol and water (30% glycol solution) is the best coolant to use in a wine tank cooling jacket. Some of the main benefits of using glycol as a cold water fluid are as follows:

▪ Glycol can hold heat longer than water, increasing efficiency

▪ It can provide extra lubrication for cold water pumps.

▪ Ethylene glycol has antifreeze properties so it can cool down to sub-zero temperatures without freezing and clogging cold water pipes.

6.What’s the Difference Between Air-cooled & Water-cooled Fermentation chillers?

There are two types of winery chiller: one is air-cooled fermentation chiller ,the other is water-cooled fermentation chiller ;

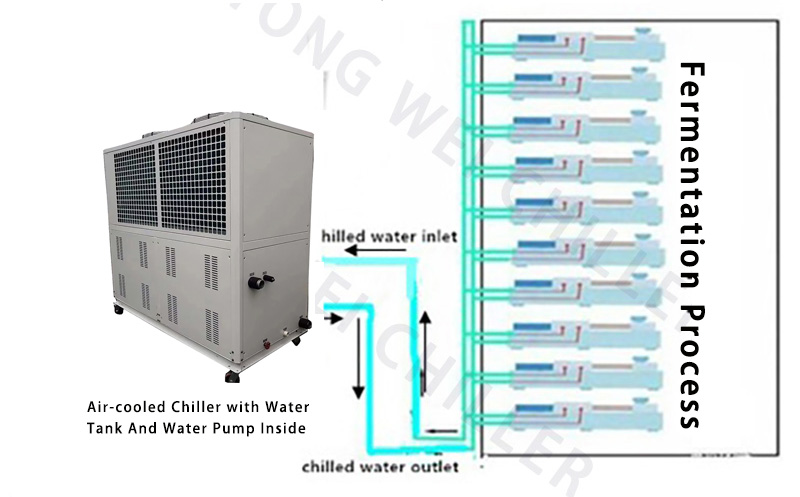

Air-cooled fermentat chillers use ambient air to dissipate heat from the wine processes. They are energy-efficient, space-saving, and less maintenance that helps save money.

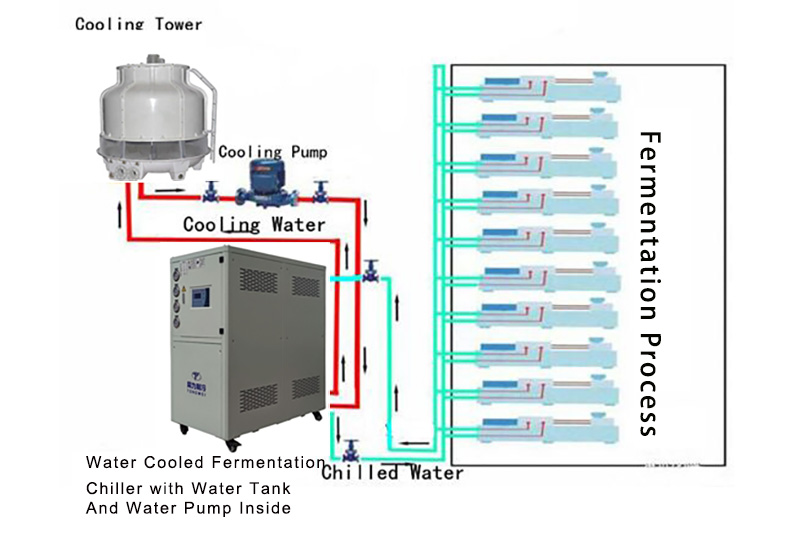

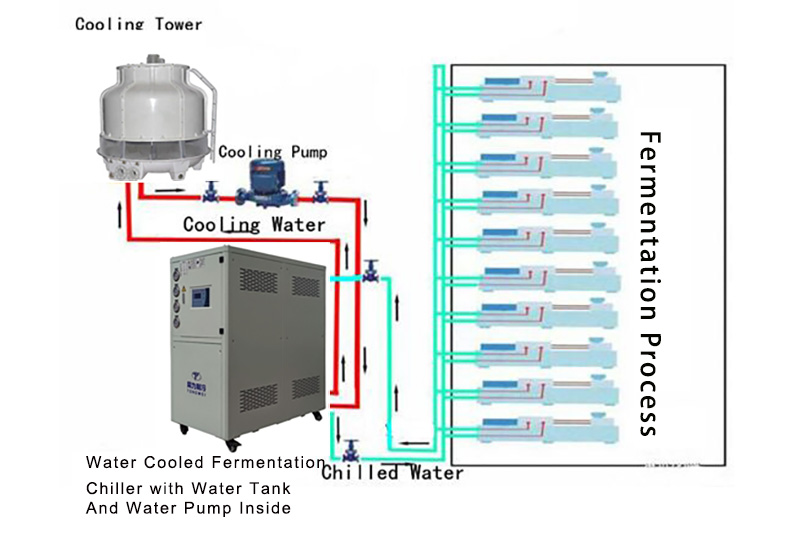

Water-cooled winery chillers use water from an external water cooling tower to dissipate heat from the winery processes. These systems are longer lifespan, Relatively quiet, and more consistent cooling performance than the air-cooled fermentation

Air-cooled Fermentation Chiller Installation Drawing

Water-cooled Fermentation Chiller Installation Drawing

We offer industrial-grade air- and water-cooled glycol winery process chillers from 1/2 ton to 200 tons to cool all sizes in fermenter. Learn more about our scroll and screw chiller systems for fermenter.

Scroll Fermentation Chiller Systems

Our single-, dual-, and multi-circuit scroll fermeter process chillers are available with scroll compressor, an industry-leading and long-lasting solution.

▪ Air- and Water-cooled Scroll

▪ 1 - 60 hp (1KW- 200KW)

▪ Single-, dual-, or multi-circuit(Three or Four )

▪ Panasonic or Danfoss scroll Compressor

20HP Air-Cooled Fermentation Chiller 40HP Water-Cooled Fermentation Chiller

20HP Air-Cooled Fermentation Chiller 40HP Water-Cooled Fermentation Chiller

Screw Fermentation Chiller Systems

Our dual- and tandem-circuit screw fermenter process chillers feature Hanbell or Bizter screw compressors for long-lasting performance and reliability.

▪ Air- and Water-cooled

▪ 60 - 300 hp (200KW-1500KW)

▪ Single or Dual-circuit

70HP Air-Cooled Fermentation Screw Chiller 70HP Water-Cooled Fermentation Screw Chiller

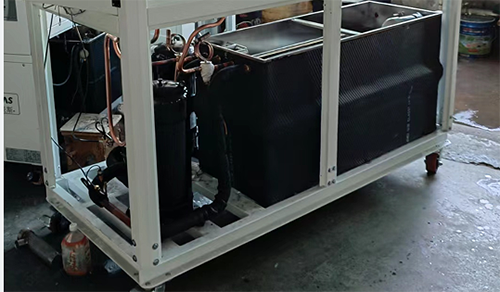

8.What Are The Main Components of Fermentation Chillers?

8.1 Compressor

The compressor is the key mover in fermenter chiller because it produces pressure variations to stir the refrigerant around.

From 1/2HP(1/2 Ton) to 60HP(5oTon) bfermentation chiller , which is with Panasonic or Danfoss brand Scroll compressor ,

Above 60HP(50 Ton) fermentation chiller , which is with Hanbell or Bitzer brand Screw compressor ,

These brand compressors are with high refrigeration efficiency,low noise ,energy saving,environmental protection and durability,safety and stability.

Panasonic Compressor

Panasonic Compressor

Danfoss Compressor

8.2 Evaporator

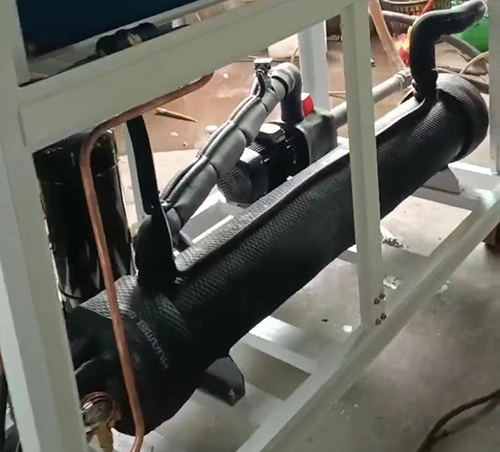

The evaporator is a crucial component of air-cooled fermentation chiller, as it is responsible for extracting heat from the liquid being cooled,it is located between the compressor and the expansion valve. There are three types of evaporators : coil in water tank evaporator , shell and tube evaporator, 304SS stainless steel plate type evaporator.

Coil in SS Water Tank Evaporator

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

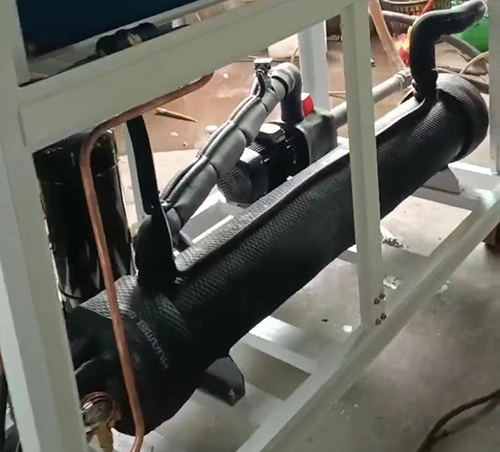

Shell and Tube Evaporator

Shell and Tube Evaporator

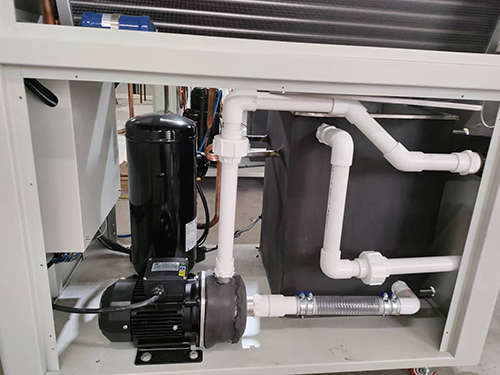

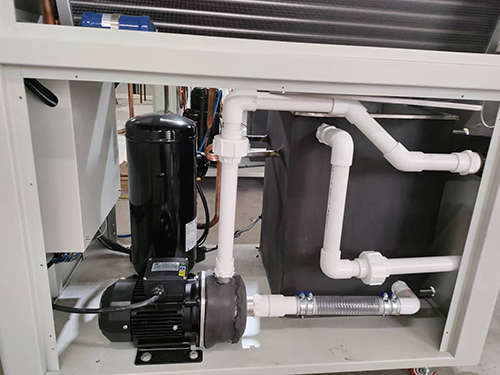

8.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

Water Pump

High Pressure Water Pump

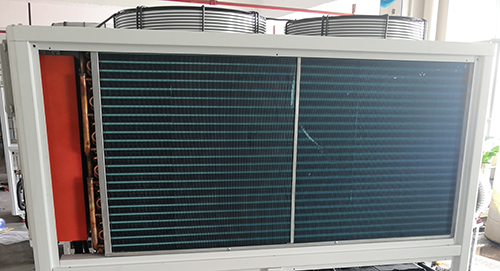

8.4 Condenser

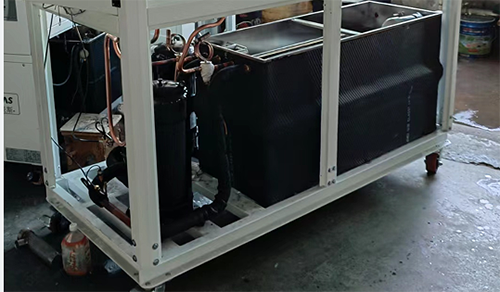

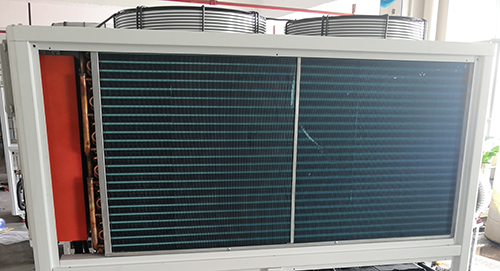

The condenser for air-cooled fermentation chiller is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser for air -cooled fermentation chiller

The condenser for water-cooled fermentation chiller is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser for water-cooled fermentation chiller

8.5 Controller Panel

Fermentation glycol chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

9.Contact Us to Learn More About Our Fermentation Glycol Chillers

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with an fermentation chiller. Contact us today for more information on a fermentation chiller.

Our probessional team will help you with any questions you have on our fermenter chiller units. We look forward to hearing from you!