Glycol Chillers

Time:2023-07-19

Views:311

1.What is Glycol Chiller ?

A glycol chiller ,also called a glycol cooling system or glycol refrigeration system, is an industrial process chiller that uses a water and glycol mixture as a coolant which allows it to efficiently transfer heat and maintain temperature control in different kinds of industrial applications, particularly in applications that involve cooling liquids or equipment.

2.Why Glycol Is Used for Cooling?

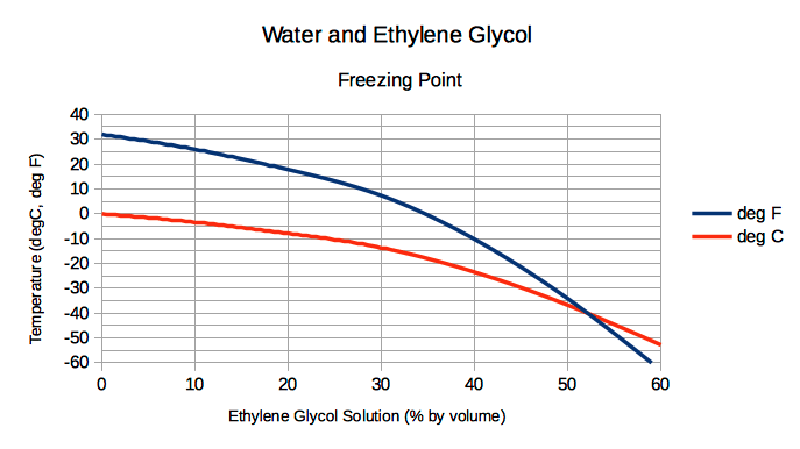

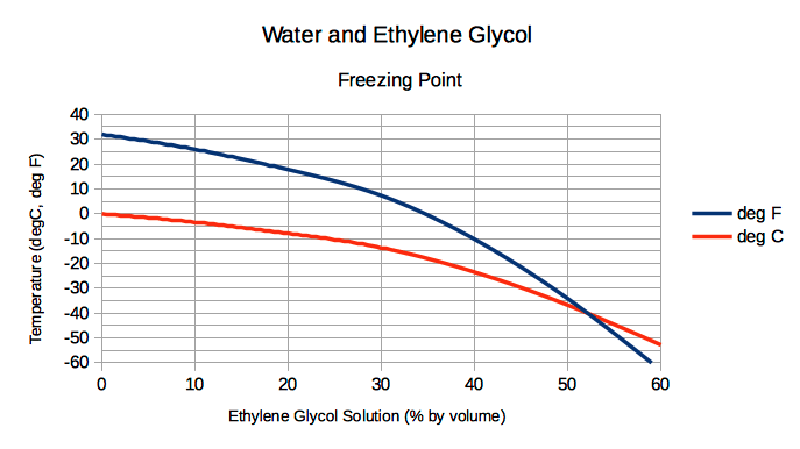

The most commonly used coolant in a chiller is water or a mixture of water-glycol. Glycol-based coolants consist of either ethylene glycol or propylene glycol. The main advantage of glycol coolants is their anti-freeze properties. Pure water freezes at 0 degrees C, while 30% ethylene glycol freezes at -14 degrees C. The low freezing point of glycol mixtures makes them ideal for cooling items that are below the freezing point of water. Although glycol has a lower heat capacity than water (each kilogram of glycol is easier to heat than one kilogram of water), the high temperature difference allows the glycol mixture to dissipate heat more quickly than pure water. The glycol mixtures are more suitable for applications where the chiller must quickly dissipate a large number of heat. In addition to providing excellent heat transfer parameters, glycol tends to discourage algae growth in heat transfer equipment.

Comparison of Ethylene Glycol and Propylene Glycol

Comparison of Ethylene Glycol and Propylene Glycol

Property Ethylene Glycol Propylene Glycol

Freeze point depression More effective Less effective

Heat transfer efficiency/capacity Better Less

Viscosity Lower Higher

Flammability Low Low

Chemical Oxygen Demand Low Higher

Biodegrading Degradesin 10-30 days Needs more than 20-30 days to degrade

Carcinogenic No No

Toxic High level of acute when taken orally, Lower level of acute

targets the kidneys

targets the kidneys

Skin Irritant Low Low

Ethylene Gycol And Propylene Glycol

3.How Does A Glycol Chiller Work?

A glycol chiller is composed of a refrigeration component and tubing containing a water-glycol mixture as coolant. Chilled fluid from the refrigeration unit is channeled through the piping associated with a thermal exchanger surrounding a heated process. After absorbing heat from the associated process, the hot coolant is returned to the refrigeration unit for cooling after which the process is repeated.

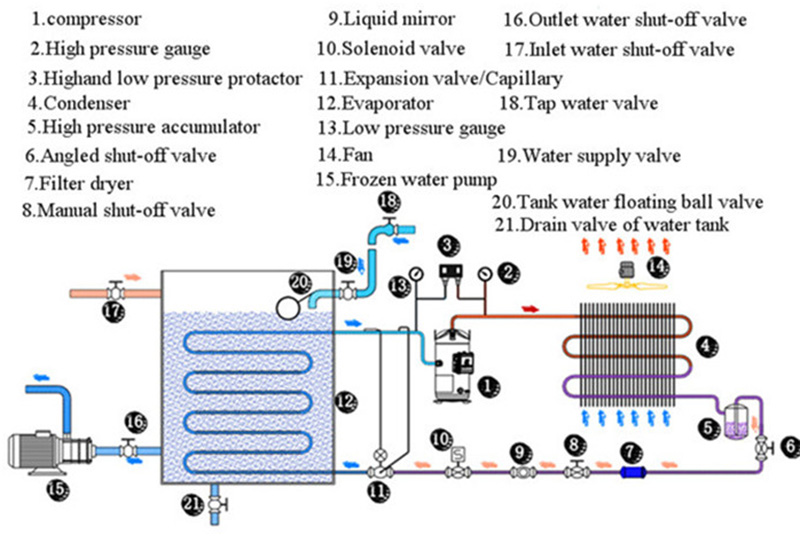

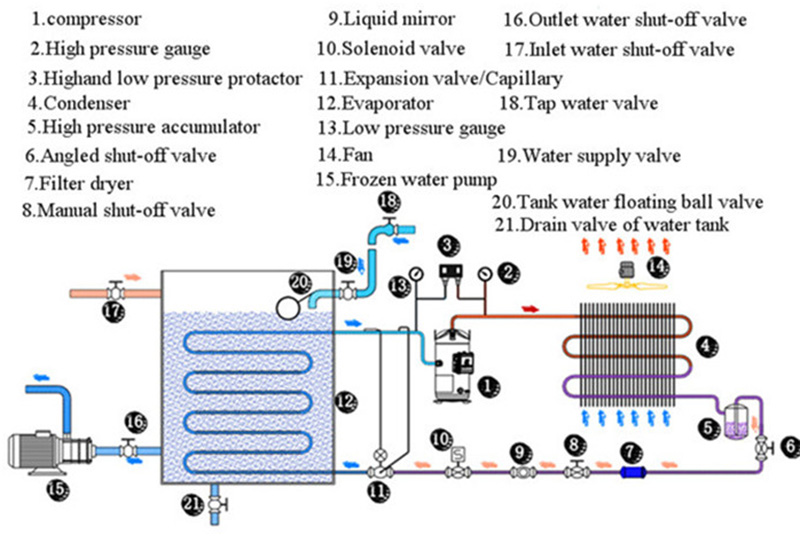

A glycol chiller consists of a compressor, an evaporator, a condenser, a throttling element, and an electric control system. Let’s see what’s the working principle of a glycol chiller:

Glycol Chiller Working Principle

The Ratio of Water to Glycol to Use

It is important to use the proper ratio of glycol to water mixture in the cooling system depends on the coldest temperature you need during operation, as insufficient glycol can cause the system to freeze, possibly bursting pipes and even destroying the chiller evaporator even may damage the glycol chiller, while too much glycol to a chiller system will result in an inefficient system.

But what’s the best ratio for glycol and water mixtures? Pls see below glycol ratio of glycol and water mixtures for the glycol chillerin your cooling process:

Glycol Water Water Temperature

Glycol Water Water Temperature

16% 84% 0℃

24% 76% -5℃

32% 68% -10℃

40% 60% -15℃

45% 55% -20℃

50% 50% -25℃

55% 45% -30℃

Glycol Chiller for Cider Mills

Glycol Chiller for Distilleries

Glycol Chiller for Dairy Product

6.How to Choose Right Glycol Chiller for your Application?

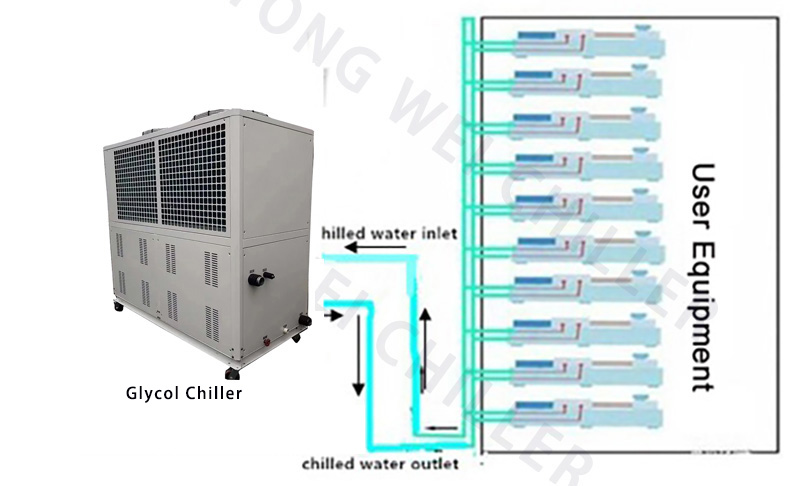

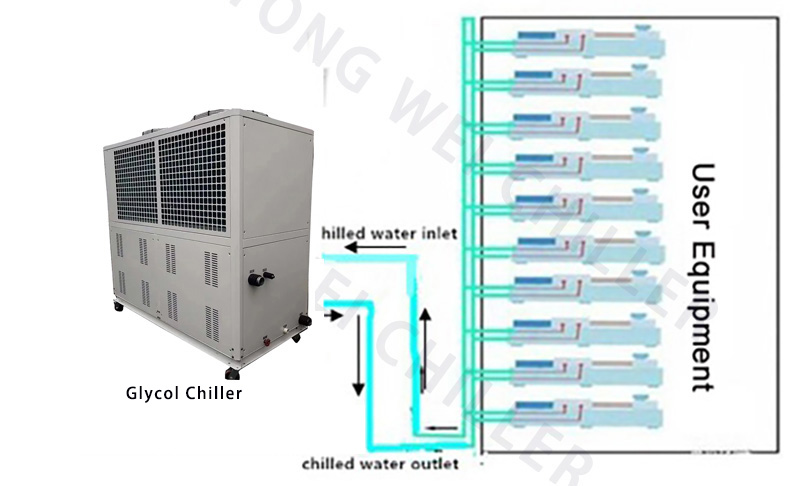

Air-cooled Glycol Chiller Installation for Reference

Air-cooled Glycol Chiller Installation for Reference

4.What Applications Can A Glycol Chiller Be Used For?

Glycol chiller is a specific kind of cooling system,which is used to cool a variety of liquids and other industrial applications.

By using a glycol chiller can achieve the low temperature for your industrial usage you need .

Glycol chillers are most used for below these Industries:

4.1 Breweries

In breweries, the glycol chiller is used for cooling the wort,Controlling Fermentation,Crash Cooling Vessels,Prepackaging and Product Storage.

Glycol Chiller for Breweries

4.2 Wineries

Glycol chillers are widely used in the fermentation process, cold stabilization and room cooling purposes.

Glycol Chiller for Wineries

4.3 Cider Mills

Fermentation control needs critical water temperature control. Glycol chiller can provide cold chilling of the juice and milk, also the cold storage of the final product.

Glycol Chiller for Cider Mills

4.4 Distilleries

During the fermentation process, the glycol chiller will provide a steady coolant for circulation between distillation tanks & stills for heat removal purposes.

Glycol Chiller for Distilleries

4.5 Food Industry

Glycol chillers can provide low-temperature coolant to guarantee the safety and consistent quality of frozen foods, food processing companies need a low-temperature cooling day in and day out.

Glycol Chiller for Food Industry

4.6 Dairy Product

A properly designed dairy glycol chiller can cool the milk very rapidly to help keep milk temperatures (and bacteria growth) under control as it is transferred from the milking parlor to its insulated tank.

Glycol Chiller for Dairy Product

5.Our Glycol Chillers

We offer industrial-grade air- and water-cooled glycol process chillers from 1/2 ton to 200 tons to cool all sizes in process. Learn more about our scroll and screw chiller systems for fermenter.

Scroll Glycol Chiller Systems

Our single-, dual-, and multi-circuit scroll fermeter process chillers are available with scroll compressor, an industry-leading and long-lasting solution.

▪ Air- and Water-cooled Scroll

▪ 1 - 60 hp (1KW- 200KW)

▪ Single-, dual-, or multi-circuit(Three or Four )

▪ Panasonic or Danfoss scroll Compressor

20HP Air-Cooled Glycol Chiller 40HP Water-Cooled Glycol Chiller

20HP Air-Cooled Glycol Chiller 40HP Water-Cooled Glycol Chiller

Screw Glycol Chiller Systems

Our dual- and tandem-circuit screw fermenter process chillers feature Hanbell or Bizter screw compressors for long-lasting performance and reliability.

▪ Air- and Water-cooled

▪ 60 - 300 hp (200KW-1500KW)

▪ Single or Dual-circuit

70HP Air-Cooled Glycol Screw Chiller 70HP Water-Cooled Glycol Screw Chiller

70HP Air-Cooled Glycol Screw Chiller 70HP Water-Cooled Glycol Screw Chiller

6.How to Choose Right Glycol Chiller for your Application?

It is very important to select the right glycol Chiller for application process, if you want proper and durable cooling,please see blow key points:

1.Air-Cooled Glycol Chiller or Water-Cooled Glycol Chiller

There are two types of glycol chiller: one is air-cooled type, the other one is water-cooled type.

Air Cooled glycol chillers use aluminum fin+fan as condensers that is similar to the “radiators” in a car.They use a fan to force air through the refrigerant coil. Unless they are specifically designed for high ambient conditions, air-cooled condensers need to operate effectively at an ambient temperature of 45℃ or less.

Air Cooled glycol chiller use shell and tube as condensers.The heat enters the condenser water from the refrigerant vapor. The warm condenser water is then pumped to the water cooling tower, where the heat from the process is eventually vented to the atmosphere.

Air-cooled Glycol Chiller Installation for Reference

Air-cooled Glycol Chiller Installation for Reference

2.Cooling capacity

When you choose a suitable chiller model , you need to know the cooling capacity in KW/TON.How to calculate the cooling capacity you need? Please see the below formula:

Cooling Capacity(kw)= Flow Rate(m3/h)*Temp Change(T1-T2)/0.86

Heat Load= C(specific heat)* M(quality output per hour )*Temp Change(T1-T2)

Oversize the chiller by 20% Ideal Size in KW = KW x 1.2

Noted : T1:Incoming Water Temperature (℃) T2:Required Chilled Water Temperature(℃)

For example, what size of chiller is required to cool 5m³ water from 25°c to 15 °c in 1 hour?

Temperature Differential = 25℃-15℃=10℃

Water Flow Rate = 5 m³/hour

Cooling Capacity in KW = 5 x 10 ÷ 0.86 = 58,14 KW

Oversize the chiller = 58.14 x 1.2 = 69.76 KW

69.96kw cooling capacity for chiller is required.

3.Power

Different countries and regions have different standards for industrial electricity, the common power supplies are 208-230V, 380-420V,440-480V,50Hz or 60Hz, 3phase.

Such in Philippines ,the power supply is 220V 60HZ 3PH , 380V 60HZ 3PH ,460V 60HZ 3PH;

in Singapore and Malaysia ,the power supply is 415V 50HZ 3PH;

in Mexico ,the power supply is 220V 60HZ 3PH;

In USA ,the power supply is 208V 60HZ 3PH;575V 60HZ 3PH;480V 60HZ 3PH and so on

4.Water Pump

When you decide the capacity/tonnage of the chiller, we will recommend you the suitable pump in KW,which standard water pump is about 2 bar .If you need more high water pressure , please us when you inquiry.

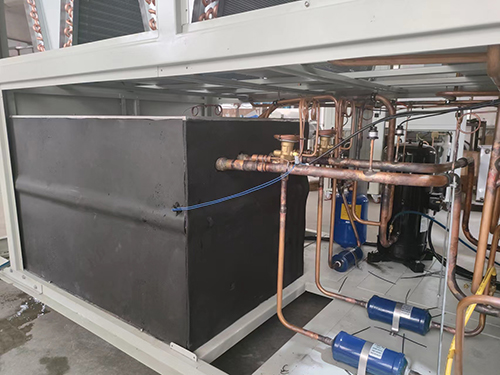

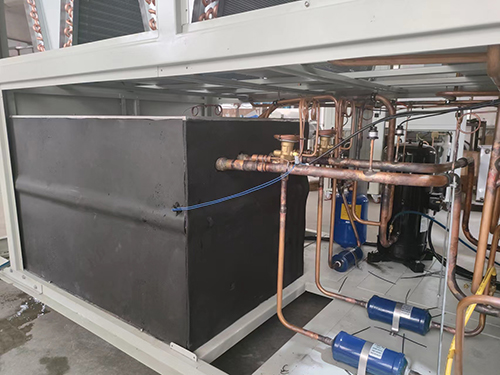

5.Evaporator Choose

Chillers generally have two types of evaporators: one is coil in water tank evaporator ,the other one is shell and tube evaporator.

Coil and tank evaporator, which has a built-in water storage tank for more convenient use,so there’s no need for extra buffer tanks. This is also our standard evaporator for chiller , if you don’t have buffer tank ,we just use this evaporator for your chiller.

Shell and tube type evaporator, which requires an additional water buffer tank to connect .The buffer tank’s capacity can be customized according to specific needs. It can buffer a larger heat load, and store more chilled water, but the installation will be more troublesome.

Water Tank Inside Chiller

7.Get a Quote on Glycol Chillers Now

As a leading industrial chiller manufacturer,we engineer and produce high-quality process chillers compatible with a broad range of industrial processes.

Depending on your needs, we also offer custom chillers to ensure that each client receives the industrial chiller best suited to their unique process.

Request a quote now on our glycol chillers or learn about the other air-cooled chillers and water-cooled chillers.