Laser Chiller

|

Content Table

▷ 1.What is Laser Water Chiller ? 5.1 Compressor

5.2 Evaporator

5.3 Water Pump

5.4 Condenser

5.5 Controller Panel

|

Now, we have installed many chillers in laser machines cooling where our experience and expertise are meeting the needs of laser process around the world.

1.What is Laser Water Chiller ?

Small Laser Chiller

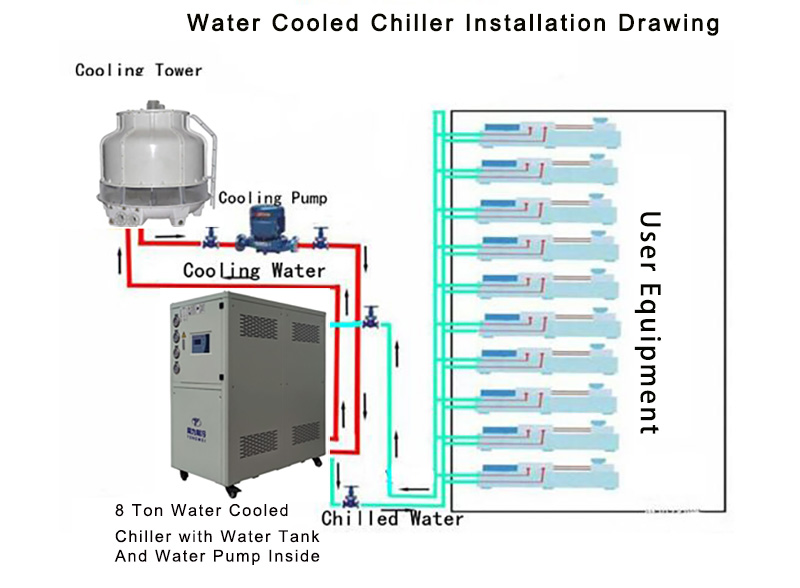

Water-cooled laser chillers use water from an external water cooling tower to dissipate heat from the brewing processes. These systems are longer lifespan, Relatively quiet, and more consistent cooling performance than the air-cooled laser chiller.

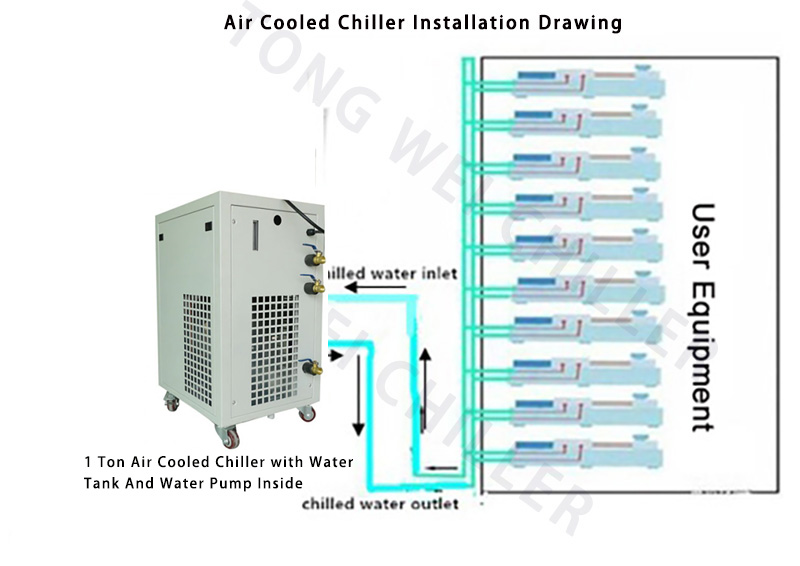

Air-cooled Laser Chiller Installation Drawing

Water-cooled Laser Chiller Installation Drawing

Should you choose an air-cooled or water-cooled laser chiller? Contact Us for help determining the best solution for you.

5.What Are The Main Components of Laser Chillers?

Panasonic Compressor

Danfoss Compressor

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

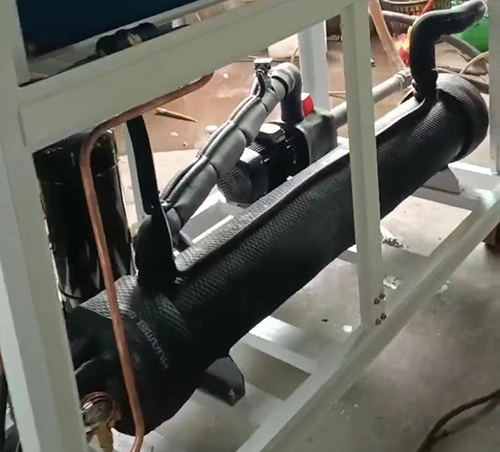

Shell and Tube Evaporator

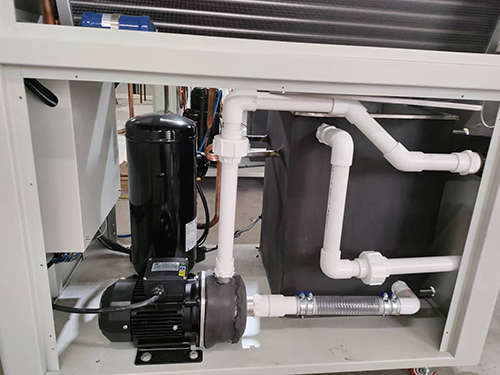

5.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

Water Pump

High Pressure Water Pump

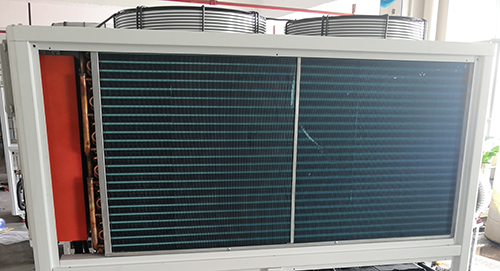

5.4 Condenser

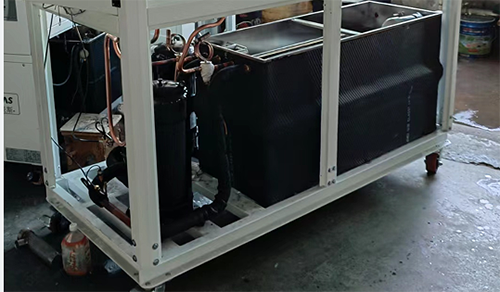

The condenser for air-cooled laser cooler is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser for air -cooled brewery chiller

The condenser for water-cooled laser cooler is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser for water-cooled laser chiller

5.5 Controller Panel

Laser Water chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

▪ Chilled 0utlet water temperature control 7℃ to 25℃

7.What are the Applications of Industrial Laser Chiller?

Laser Chiller is right now utilized in industries for a wide range of processes including:

Drilling: The laser water chiller ensures more stable drilling, as well as ensures the stability of the drill rig and the pipe.

Laser chillers balance out the permafrost, allowing drilling into solid formations. Drilling without a laser water chiller reduces the stability of the rig and drilling tools.

The heat generated by drilling not only affects surface operations but also creates rough drilling conditions.

Welding: Utilizing a powerful fiber laser to weld two pieces of metal together, creating a strong connection between them.

Laser water chiller stabilizes the temperature of the fiber laser machine and improves the electrode tip,which increases the service life of the laser machine.

Poor temperature control of the welding rod will lead to early deterioration of the welding rod and reduce welding quality. It‘s always a plus point to use the appropriate laser chiller for your fiber laser application.

Cutting: Lasers are used to cut a range of different materials instead of traditional blades.

Due to the heat generated by the laser and the cutting itself, the temperature rises and deteriorates the beam quality, affecting the cutting.

A laser chiller can cool your laser head and laser source. By using a laser chiller, the laser can work properly in hot and cold conditions.

The laser chiller ensures that your laser cutting machine works normally at a constant temperature.

Perforating: In the food processing industry, lasers punch holes in packaging such as fruits and vegetables.

Since most of these packaging materials are plastic, it is difficult to keep the laser at normal operating temperature. Excessive heat can cause larger holes than normal, rendering your packaging unusable.

That‘s why laser chillers are designed to deliver superior performance.

Treatment: In the medical field, lasers are becoming doctors‘ right-hand assistants. From ophthalmology, dentistry, spine, plastic surgery to cancer treatments and treatments, lasers are with patients every day.

Because of their role, lasers need to stay cool and provide accurate and efficient performance.

>With the help of a laser water chiller, your laser beam will remain in the ideal position for any kind of surgery.

Whether you are in the manufacturing, food or medical industry. You need a laser chiller to get better results for your laser applications.

How to calculate right cooling capacity for your laser chillers?

Cooling Capacity(kw)= Flow Rate(m3/h)*Temp Change(T1-T2)/0.86

Heat Load= C(specific heat)* M(quality output per hour )*Temp Change(T1-T2)

Water Flow Rate = 5 m³/hour

There are two types of chiller :Air Cooled Laser Chiller and Water Cooled Laser Chiller.

9.Contact Us to Learn More About Our Laser Water Chillers

We engineer and produce high-quality process chillers compatible with a broad range of industrial processes.

Depending on your needs, we also offer custom chillers to ensure that each client receives the industrial chiller best suited to their unique process.

Request a quote now on our laser water chillers or learn about the other air-cooled chillers and water-cooled chillers we offer.