Tongwei Chiller is specialized in manufacturing packaged chiller and portable chiller to reduce the temperature in plasma process.

Now, we have installed many chillers in plasma cutting and plasma spray cooling where our experience and expertise are meeting the needs of plasma cutting process around the world.

We can also custom design and manufacture laser water chillers to meet your specific needs.If you need a plasma cutting chiller for a different plasma cutting and plasma spray process? Contact Us–we’re here to help.

1.What is Plasma Cutting Chiller ?

Plasma cutting Chiller is a process cooling machine that is used to control temperature during spray processing by releasing out heat from the equipment.

The plasma cutting process uses an accelerated jet of hot plasma to transfer energy to the conductive work material. Plasma cutting is commonly used in industrial construction, manufacturing shops, salvage and scrap operations, and automotive repairs.

In these applications,plasma cutting chillers are used to provide stable temperatures during the plasma cutting process. Plasma cutting chillers maintain the integrity of your plasma cutting system with superior performance, providing years of reliable liquid temperature control.

Plasma Cutting Chiller

2.What are the benefits of Plasma Cutting?

▪ Plasma cutting is simple to use so it can be operated by hand or robot.

▪ Plasma cutting is more economical than other types of cutting.

▪ Plasma cutting can be used on a wider range of materials, such as stainless steel and aluminum. unlike laser cutting or oxy-fuel cutting, plasma cutting has a high-quality cut edge, which means it doesn‘t leave jagged edges on the cut edges.

Plasma Cutting

3.Why are Plasma Cutting Chillers Useful?

In order to achieve the above goals, the key is to remove the heat during the plasma cutting process, which can be achieved through a plasma cutting cooler cooling system. It can be designed in various refrigeration capacities to meet customers‘ specific cooling requirements.

4.What’s the Difference Between Air-cooled & Water-cooled Plasma Cutting Chillers?

There are two types of plasma cutting chiller: one is air-cooled plasma cutting chiller ,the other is water-cooled plasma cutting chiller ;

Air-cooled plasma cutting chillers use ambient air to dissipate heat from the brewing processes. They are energy-efficient, space-saving, and less maintenance that helps save money.

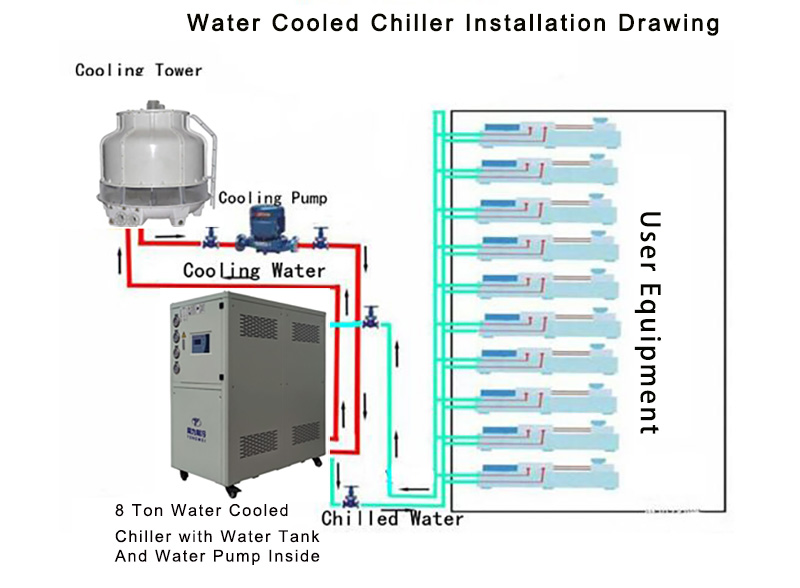

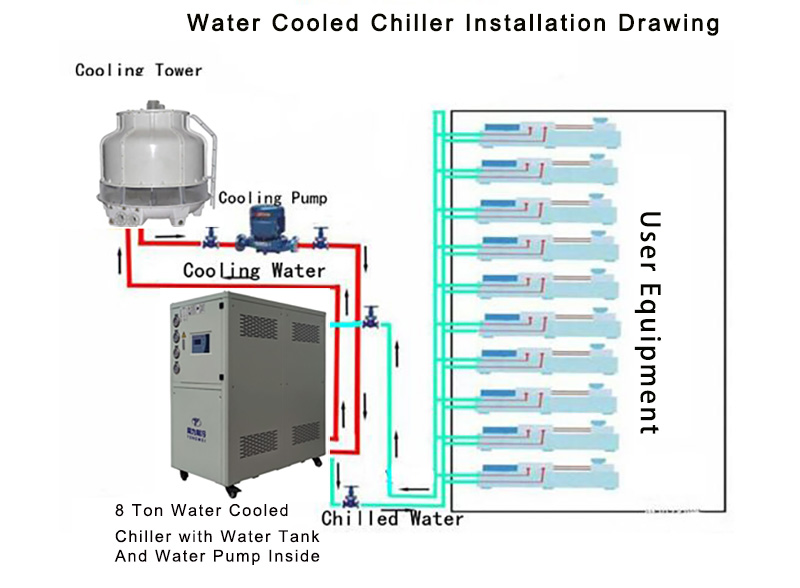

Water-cooled plasma cutting chillers use water from an external water cooling tower to dissipate heat from the brewing processes. These systems are longer lifespan, Relatively quiet, and more consistent cooling performance than the air-cooled pl chiller.

Air-cooled Plasma Cutting Chiller Installation Drawing

Water-cooled Plasma Cutting Chiller Installation Drawing

Should you choose an air-cooled or water-cooled plasma cutting chiller? Contact Us for help determining the best solution for you.

5.What is the Difference Between Plasma Cutting Scroll Chiller and Plasma Cutting Screw Chiller?

Plasma Cutting Scroll Chiller Plasma Cutting Screw Chiller

▪1/2 HP-60HP(2KW-170KW) Above 60HP(Above 170KW)

▪ Danfoss/Panasonic Scroll Compressor Hanbell/Bitzer Screw compressor

▪Built with water tank and water pump Without water tank and water pump

Air-cooled Plasma Cutting Scroll Chiller Air-cooled Plasma Cutting Screw Chiller

Water-cooled Plasma Cutting Scroll Chiller Water-cooled Plasma Cutting Screw Chiller

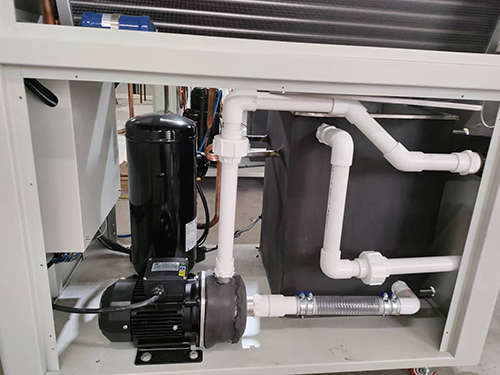

6.What Are The Main Components of Plasma Cutting Chillers?

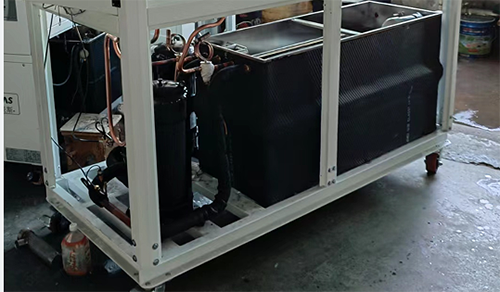

6.1 Compressor

The compressor is the key mover in water chiller because it produces pressure variations to stir the refrigerant around.

From 1/2HP(1/2 Ton) to 60HP(5oTon) plasma cutting chiller , which is with Panasonic or Danfoss brand Scroll compressor ,

Panasonic Compressor

Panasonic Compressor

Danfoss Compressor

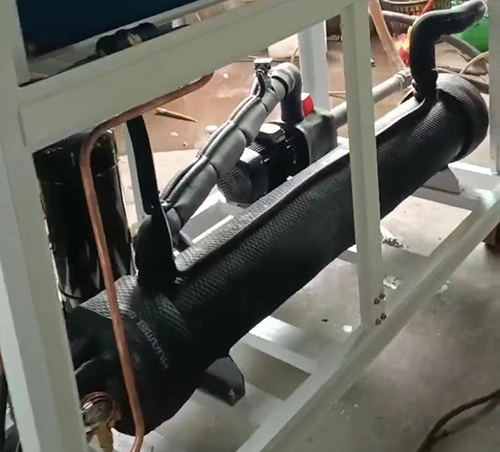

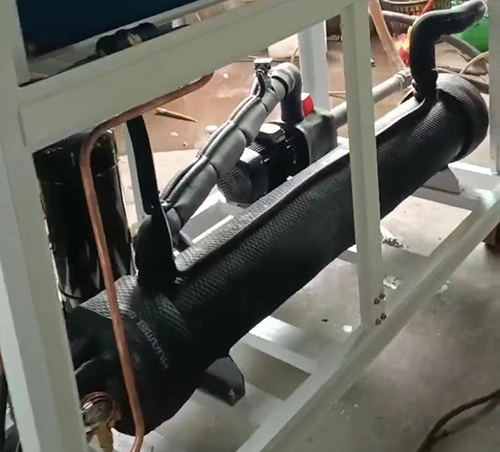

6.2 Evaporator

The evaporator is a crucial component of air-cooled water chiller, as it is responsible for extracting heat from the liquid being cooled,it is located between the compressor and the expansion valve. There are three types of evaporators : coil in water tank evaporator , shell and tube evaporator, 304SS stainless steel plate type evaporator.

Coil in SS Water Tank Evaporator

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

Shell and Tube Evaporator

Shell and Tube Evaporator

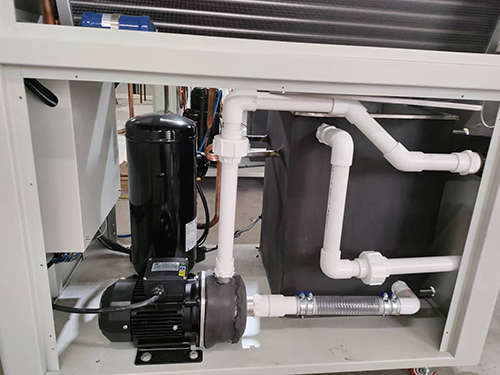

6.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

Water Pump

High Pressure Water Pump

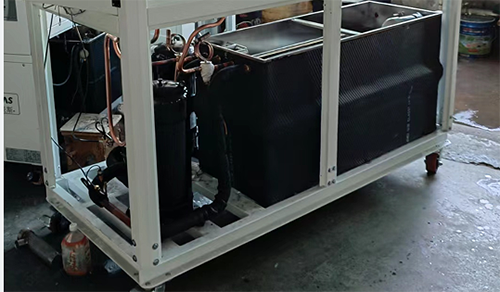

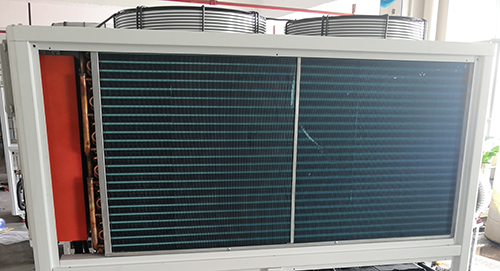

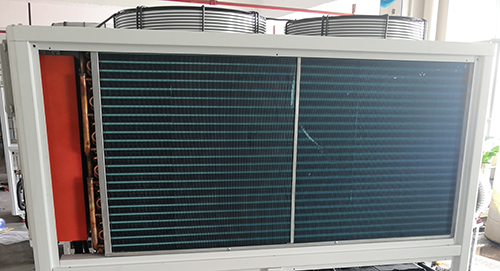

6.4 Condenser

The condenser for air-cooled plasma cutting cooler is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser for air -cooled plasma cutting chiller

The condenser for water-cooled plasm spray cooler is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser for water-cooled plasma cutting chiller

6.5 Controller Panel

Water chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

7. What are the Key Features of a Plasma Cutting Chiller?

▪ Energy-efficient Panasonic/Danfoss compressor

▪ 304 Stainless steel water pump

▪ Chilled 0utlet water temperature control 7℃ to 25℃

▪ Precise temperature controller

▪ Environment-friendly refrigerant R407c/r410a

▪ PID temperature controller

▪ Easy installation ,operation and low cost of maintenance

▪ 304 Stainless Steel Coil in SS water tank as evaporator

8.How to Choose Right Laser Chiller for Your Plasma Cutting Process?

How to calculate right cooling capacity for your plasma cutting chillers?

One of the most frequently ask about how we can know the cooling capacity for chillers.

The range of a chiller at which it can discharge heat from a heated fluid is called cooling capacity.

The cooling capacity of a laser Chiller ranges from 1/2KW to 100KW.

Let’s see the below formula.

Cooling Capacity(kw)= Flow Rate(m3/h)*Temp Change(T1-T2)/0.86

Heat Load= C(specific heat)* M(quality output per hour )*Temp Change(T1-T2)

Oversize the chiller by 20% Ideal Size in KW = KW x 1.2

Noted : T1:Incoming Water Temperature (℃) T2:Required Chilled Water Temperature(℃)

For example, what size of chiller is required to cool 5m³ water from 25°c to 15 °c in 1 hour?

Temperature Differential = 25℃-15℃=10℃

Water Flow Rate = 5 m³/hour

Cooling Capacity in KW = 5 x 10 ÷ 0.86 = 58,14 KW

Oversize the chiller = 58.14 x 1.2 = 69.76 KW

69.96kw cooling capacity for chiller is required.

Types of plasma cutting chiller system?

There are two types of chiller :Air Cooled Plasma Cutting Chiller and Water Cooled Plasma Cutting Chiller.

Water cooled chiller needs a separated water cooling tower and water cooling pump ,if you don‘t have exsiting water cooling tower,we suggest you use air cooled chiller; But if your ambiemt temperature is very high above 55℃ ,we suggest you use water cooled chiller , as it is easier to dissipate heat for water cooled chiller with water cooling tower.

Whether chillers need built-in Tank or not?

In a chiller system, a tank is usually equipped to buffer the thermal load of the chiller.

But should we choose a built-in type of tank or an external type of tank?

A chiller with a built-in tank is easier to install and can be used simply by connecting a water pipe to your application.

But it has a limited capacity and is not suitable for applications with larger chilled water demands.External tank’s capacity can be customized according to specific needs.

It can buffer a larger heat load, store more chilled water, but the installation will be more troublesome.

If you don‘t have external water tank ,we suggest our chiller built-with water tank ,which is easy for you to install.

Cooling capacity unit conversion?

1 KW=860 kcal/h ;

1 TON=3.517 KW;

1 KW=3412 Btu/h;

9.Contact Us to Learn More About Our Plasma Cutting Chillers

We engineer and produce high-quality process chillers compatible with a broad range of industrial processes.

Depending on your needs, we also offer custom chillers to ensure that each client receives the industrial chiller best suited to their unique process.

Request a quote now on our plasma cutting water chillers or learn about the other air-cooled chillers and water-cooled chillers.