Plastic Process Cooling Chiller

Plastic Process Cooling Chiller

Plastic Industry

3.What’s the Difference Between Air-cooled & Water-cooled Plastic Process Chillers?

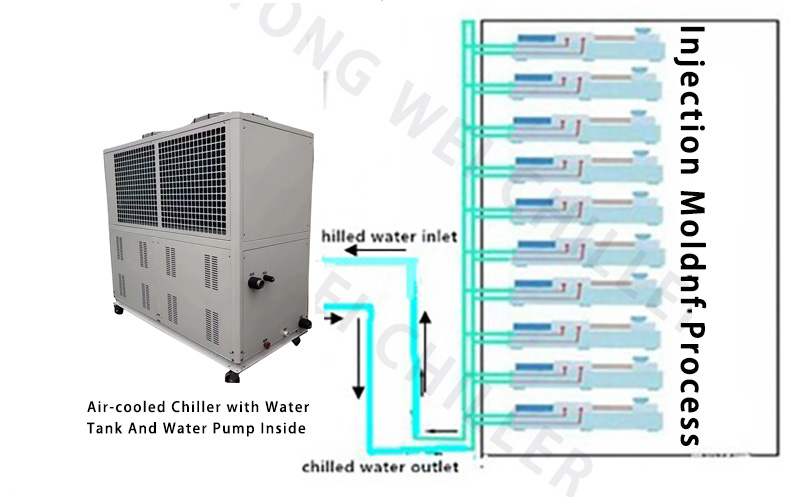

There are two types of Injection Moldingchiller: one is air-cooled Plastic Process chiller ,the other is water-cooled plastic process chiller ;

Water-cooled plastic process chillers use water from an external water cooling tower to dissipate heat from the brewing processes. These systems are longer lifespan, Relatively quiet, and more consistent cooling performance than the air-cooled Plastic Processchiller.

Plastic Process Scroll Chiller Plastic Process Screw Chiller

▪1/2 HP-60HP Above 60HP

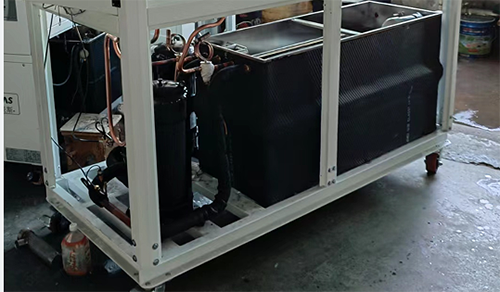

▪ Danfoss/Panasonic Scroll Compressor Hanbell/Bitzer Screw compressor

▪Built with water tank and water pump Without water tank and water pump

Air-cooled Plastic Process Scroll Chiller Air-cooled Plastic Process Screw Chiller

5.What Are The Main Components of Plastic Process Chillers?

Above 60HP Plastic Processchiller,which is with Hanbell or Bitzer screw compressor;

Panasonic Compressor

Danfoss Compressor

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

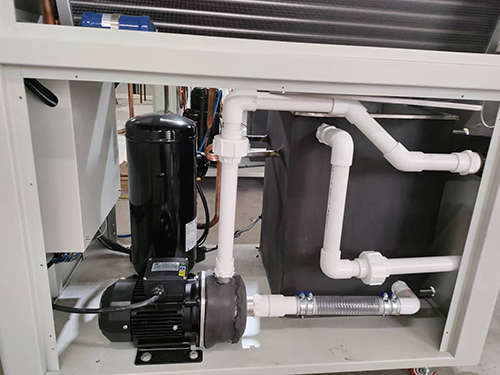

5.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

Water Pump

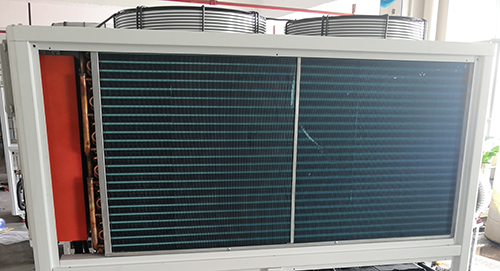

5.4 Condenser

The condenser for air-cooled Plastic Process cooler is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser for air -cooled Plastic Processchiller

The condenser for water-cooled Plastic Process cooler is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser for water-cooled Plastic Processchiller

5.5 Controller Panel

Controller Panel

7.How to Choose Right Plastic ProcessChiller for Your Plastic Process Process?

There are two types of chiller :Air Cooled Plastic Process Chiller and Water Cooled plastic process Chiller.

But Most customers use air cooled Injection Moldingchiller ,which is more easily install and save space.

8.Get a Quote on Industrial Plastic Process Chillers Now

As a leading industrial chiller manufacturer,we engineer and produce high-quality process chillers compatible with a broad range of industrial processes.

Depending on your needs, we also offer custom chillers to ensure that each client receives the industrial chiller best suited to their unique process.

Request a quote now on our industrial plastic process chillers or learn about the other air-cooled chillers and water-cooled chillers.

.jpg)