Tongwei Chiller is specialized in manufacturing packaged chiller and portable chiller to reduce the temperature in waterjet cutting process.

Now, we have installed many chillers in waterjet cutting cooling where our experience and expertise are meeting the needs of waterjet cutting process around the world.

We can also custom design and manufacture water chillers to meet your specific needs.If you need a waterjet cutting chiller for a different waterjet cutting process? Contact Us–we’re here to help.

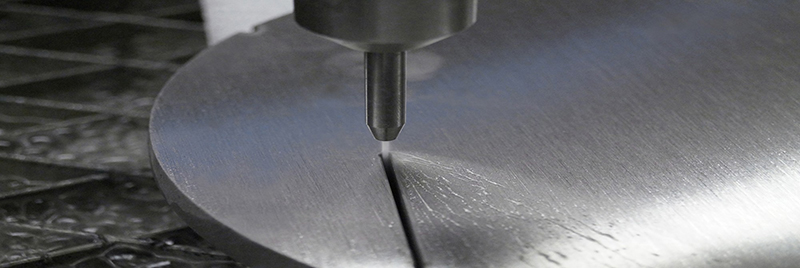

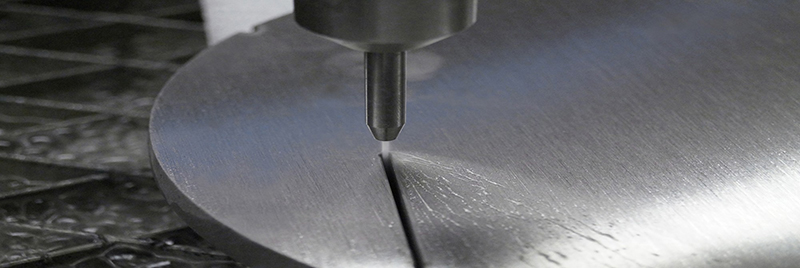

1.What is Waterjet Cutting?

Waterjet cutting is simply an accelerated erosion process within a selected material. Highly pressurised water is fired through a ruby or diamond nozzle into a mixing chamber. This pressure creates a vacuum and draws garnet sand into the stream where it is then fired at the object in place for cutting. The sand particles eat away at the material causing the effect of erosion to take place at such a high speed it is deemed as cutting. This has allowed waterjet cutting to become an extremely powerful and versatile tool that is used in many industries around the world.

Waterjet Cutting

2.What is Waterjet Cutting Machine?

A waterjet cutting machine is a three-main-component machine that uses a high-pressure stream of water to erode narrow lines within a piece of material. Depending on the density and compound of the material, such as titanium, particulate abrasives are added to the water jet to increase cutting power. The abrasive is added at the nozzle for easily switching between water and abrasive cutting.

3.What Are The Advantages of Waterjet Cutting?

▪ Waterjet can cut almost any material such copper, brass, aluminum, pre-hardened and mild steel, exotic materials such titanium, inconel and hastelloy, 304 stainless steel, brittle materials suchglass, ceramics .

> ▪ Spraying water is safe because there are no toxic fumes, such as evaporating metal, and there is no risk of fire.

▪ Waterjet is environmentally friendly, with have good tolerances, low equipment costs, and are simple to operate and maintain.

▪ Waterjet can cut precise internal cuts for better edges.

4.What Is Waterjet Cuttting Chiller?

Waterjet cutting chillers are specifically designed cooling machines to handle the water used by your waterjet machine. They are manufactured from the highest quality components and operate efficiently by maintaining precise waterjet temperatures.

our water jet cutting chillers are highly cost effective and custom designed for your specific water cutting machine operation from .

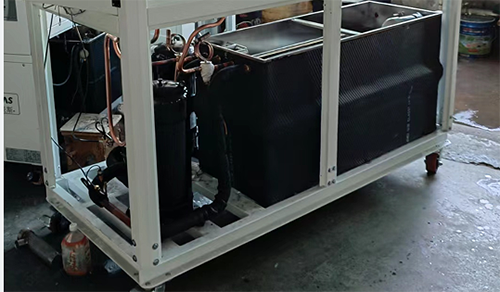

Waterjet Cutting Chiller

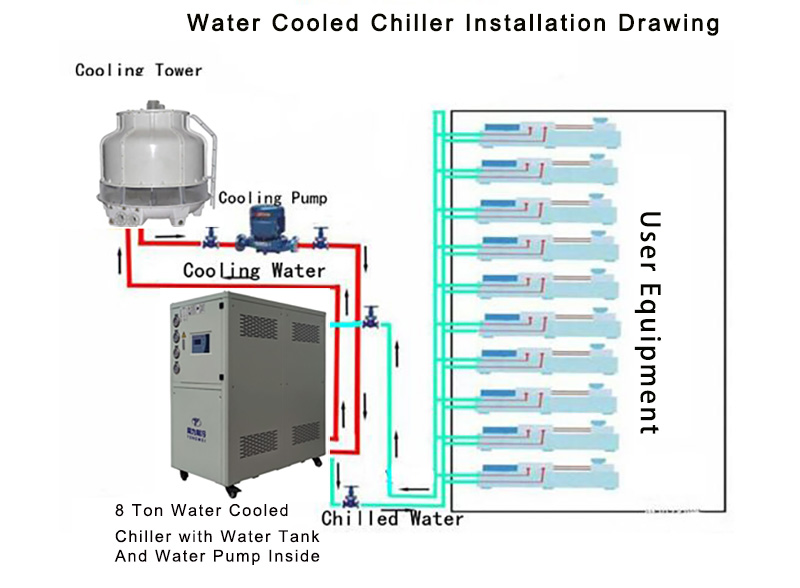

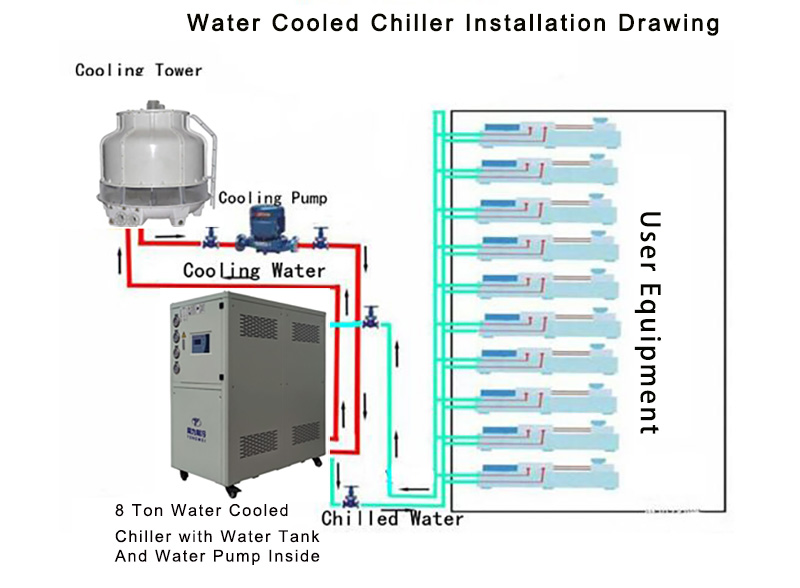

5.What’s the Difference Between Air-cooled & Water-cooled Waterjet Cutting Chillers?

There are two types of waterjet cutting chiller: one is air-cooled waterjet cutting chiller ,the other is water-cooled waterjet cutting chiller ;

Air-cooled waterjet cutting chillers use ambient air to dissipate heat from the brewing processes. They are energy-efficient, space-saving, and less maintenance that helps save money.

Water-cooled waterjet cutting chillers use water from an external water cooling tower to dissipate heat from the brewing processes. These systems are longer lifespan, Relatively quiet, and more consistent cooling performance than the air-cooled waterjet cutting chiller.

Air-cooled Waterjet Cutting Chiller Installation Drawing

Water-cooled Waterjet Cutting Chiller Installation Drawing

Should you choose an air-cooled or water-cooled waterjet cutting chiller? Contact Us for help determining the best solution for you.

6.What is the Difference Between Plasma Cutting Scroll Chiller and Waterjet CuttingScrew Chiller?

Waterjet Cutting Scroll Chiller Waterjet Cutting Screw Chiller

▪1/2 HP-60HP(2KW-170KW) Above 60HP(Above 170KW)

▪ Danfoss/Panasonic Scroll Compressor Hanbell/Bitzer Screw compressor

▪Built with water tank and water pump Without water tank and water pump

Air-cooled Waterjet Cutting Scroll Chiller Air-cooled Waterjet Cutting Screw Chiller

Water-cooled Waterjet Cutting Scroll Chiller Water-cooled Waterjet Cutting Screw Chiller

7.What Are The Main Components of Waterjet Cutting Chillers?

7.1 Compressor

The compressor is the key mover in water chiller because it produces pressure variations to stir the refrigerant around.

From 1/2HP(1/2 Ton) to 60HP(5oTon) waterjet cutting chiller , which is with Panasonic or Danfoss brand Scroll compressor ,

Panasonic Compressor

Panasonic Compressor

Danfoss Compressor

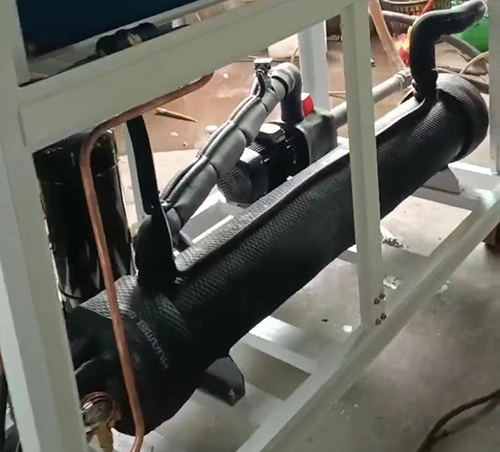

7.2 Evaporator

The evaporator is a crucial component of air-cooled water chiller, as it is responsible for extracting heat from the liquid being cooled,it is located between the compressor and the expansion valve. There are three types of evaporators : coil in water tank evaporator , shell and tube evaporator, 304SS stainless steel plate type evaporator.

Coil in SS Water Tank Evaporator

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

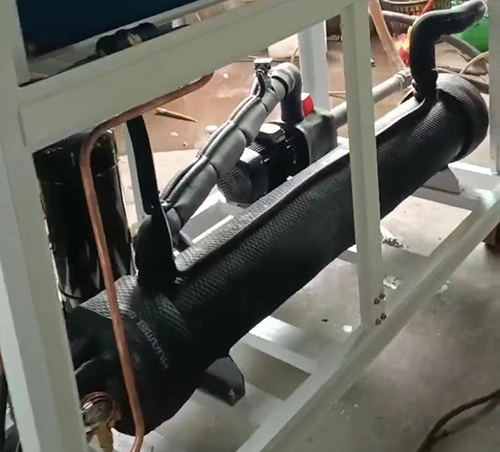

Shell and Tube Evaporator

Shell and Tube Evaporator

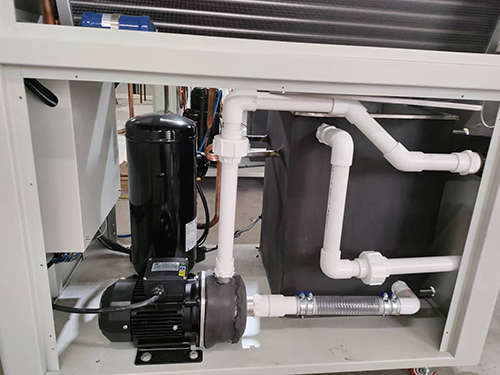

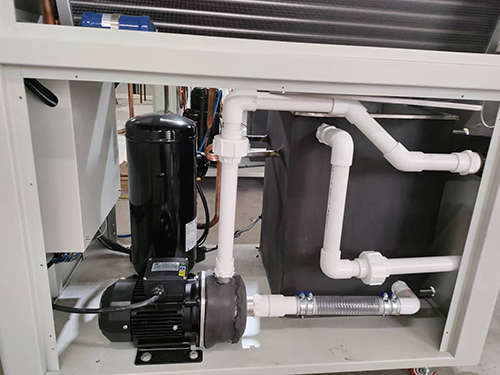

7.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

Water Pump

High Pressure Water Pump

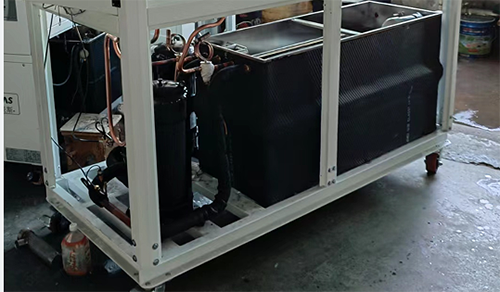

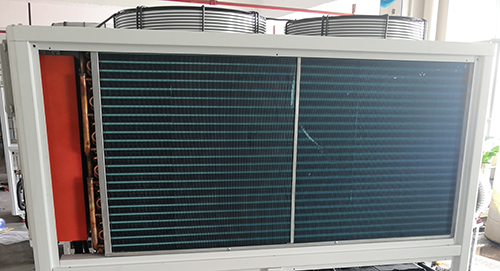

7.4 Condenser

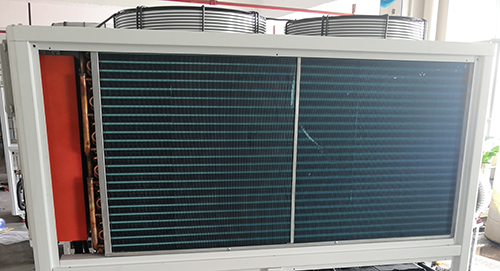

The condenser for air-cooled waterjet cutting cooler is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser for air -cooled waterjet cutting chiller

The condenser for water-cooled waterjet cutting cooler is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser for water-cooled waterjet cuttting chiller

7.5 Controller Panel

Water chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

8. What are the Key Features of a Waterjet Cutting Chiller?

▪ Energy-efficient Panasonic/Danfoss compressor

▪ 304 Stainless steel water pump

▪ Chilled 0utlet water temperature control 7℃ to 25℃

▪ Precise temperature controller

▪ Environment-friendly refrigerant R407c/r410a

▪ PID temperature controller

▪ Easy installation ,operation and low cost of maintenance

▪ 304 Stainless Steel Coil in SS water tank as evaporator

9.How to Choose Right Laser Chiller for Your Waterjet Cutting Process?

How to calculate right cooling capacity for your waterjet cutting chillers?

One of the most frequently ask about how we can know the cooling capacity for chillers.

The range of a chiller at which it can discharge heat from a heated fluid is called cooling capacity.

The cooling capacity of a laser Chiller ranges from 1/2KW to 100KW.

Let’s see the below formula.

Cooling Capacity(kw)= Flow Rate(m3/h)*Temp Change(T1-T2)/0.86

Heat Load= C(specific heat)* M(quality output per hour )*Temp Change(T1-T2)

Oversize the chiller by 20% Ideal Size in KW = KW x 1.2

Noted : T1:Incoming Water Temperature (℃) T2:Required Chilled Water Temperature(℃)

For example, what size of chiller is required to cool 5m³ water from 25°c to 15 °c in 1 hour?

Temperature Differential = 25℃-15℃=10℃

Water Flow Rate = 5 m³/hour

Cooling Capacity in KW = 5 x 10 ÷ 0.86 = 58,14 KW

Oversize the chiller = 58.14 x 1.2 = 69.76 KW

69.96kw cooling capacity for chiller is required.

Types of Waterjet Cuttingchiller system?

There are two types of chiller :Air Cooled Waterjet Cutting Chiller and Water Cooled Waterjet Cutting Chiller.

Water cooled chiller needs a separated water cooling tower and water cooling pump ,if you don‘t have exsiting water cooling tower,we suggest you use air cooled chiller; But if your ambiemt temperature is very high above 55℃ ,we suggest you use water cooled chiller , as it is easier to dissipate heat for water cooled chiller with water cooling tower.

Whether chillers need built-in Tank or not?

In a chiller system, a tank is usually equipped to buffer the thermal load of the chiller.

But should we choose a built-in type of tank or an external type of tank?

A chiller with a built-in tank is easier to install and can be used simply by connecting a water pipe to your application.

But it has a limited capacity and is not suitable for applications with larger chilled water demands.External tank’s capacity can be customized according to specific needs.

It can buffer a larger heat load, store more chilled water, but the installation will be more troublesome.

If you don‘t have external water tank ,we suggest our chiller built-with water tank ,which is easy for you to install.

Cooling capacity unit conversion?

1 KW=860 kcal/h ;

1 TON=3.517 KW;

1 KW=3412 Btu/h;

10.Contact Us to Learn More About Our Waterjet Cutting Chillers

We engineer and produce high-quality process chillers compatible with a broad range of industrial processes.

Depending on your needs, we also offer custom chillers to ensure that each client receives the industrial chiller best suited to their unique process.

Request a quote now on our waterjet cutting water chillers or learn about the other air-cooled chillers and water-cooled chillers.