Reasons And Solutions for High Pressure Alarm of Industrial Chiller System

Time:2023-11-11

Views:378

Pressure stability is an important indicator to measure whether the industrial chiller unit is working properly. When the pressure in the chiller system is too high, an alarm will be triggered, a fault signal will be sent, and the refrigeration system will stop working.

What are the causes of high-pressure alarms in industrial chiller system? How can we accurately and quickly solve the high-pressure alarm? We can quickly find and troubleshoot faults from below aspects.

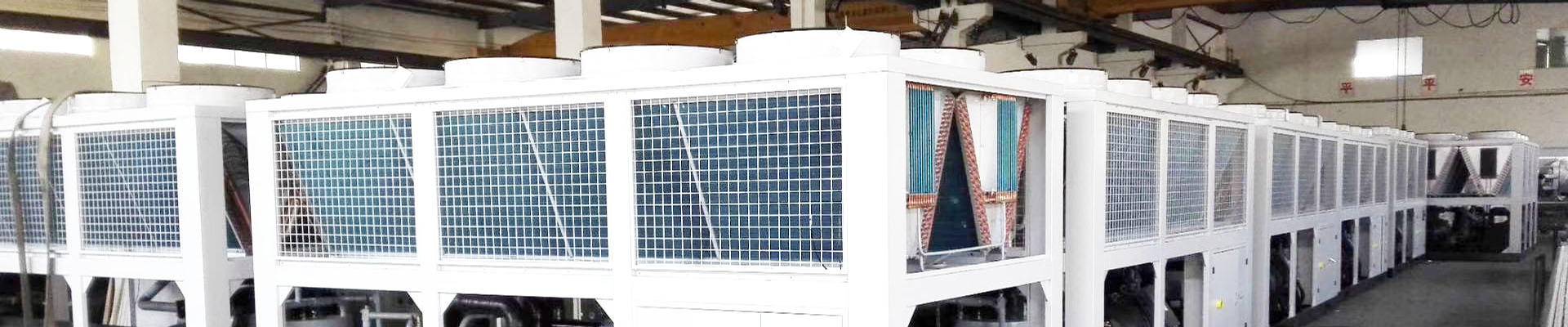

In Air cooled chiller

The Air cooled chiller is use fan and finned copper tube as condenser to dissipate heat, please refer to the following for cause and troubleshooting:

1. The air condenser function is insufficient or the ambient temperature is too high

The heat dissipation efficiency of the condenser is inefficient or the ambient temperature is very high, which means that the heat generated in the refrigeration cycle cannot be effectively removed. This fault triggers a high pressure alarm.

Solution: Check whether there are mechanical problems with the fan and remove dust and debris of condenser regular. Keeping good ventilation for air inlet and outlet is also essential for heat dissipation.For example. When you install the chiller machine is closed to the wall ,the best distance is 1-2 meters from the wall,which can with good heat dissipation.

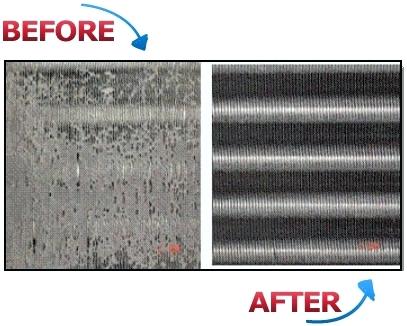

2.Condenser Clogged

A clogged condenser will prevent high-pressure refrigerant gas from condensing within the system. This blockage can cause gas to build up, which can trigger a high-pressure alarm.

Solution: Clean the inside and outside surfaces of the chiller condenser to remove accumulated dust and dirt. You can use compressed air or soft brush to clean the air duct and condenser of the chiller( aluminum fin) to ensure that the heat dissipation effect of the chiller is good.

3.Air in the chiller system

This problem usually occurs when air is mixed with the refrigeration system on a newly installed machine or compressor after maintenance. The trapped air cannot be condensed and remains in the condenser, causing a high pressure alarm.

Solution: Open the air separation valve, exhaust port or condenser inlet/outlet to discharge the trapped air.If you still don’t know how to deal with it ,you can contact us for guide you .

4.Excess refrigerant in the chiller system

Charging the system with too much refrigerant can have an effect similar to air entrapment. If too much refrigerant is added, it will not completely condense into a liquid. This excess refrigerant occupies a large part of the condenser tube, reducing the condensation effect and increasing the pressure.

Solution: Carefully drain part of the refrigerant from the low pressure side until the chiller system reaches the optimal pressure.

5.Expansion valve opening is insufficient or damaged

The expansion valve is key to converting high-pressure liquid refrigerant into a vapor state. If the valve opening is too small, high pressure will be generated at the front end of the condenser.

Solution: Gradually increase the opening of the expansion valve and reduce the pressure. If the valve is damaged, you need replace the same specification or model expansion valve .

High-pressure alarm Is mainly related to the cooling water system for water cooled chiller . Below, we discuss some common causes of high pressure in water-cooled chillers, along with recommended corrective actions:

1.Cooling water valve is closed

In water-cooled chillers, cooling water towers provide circulating cooling water. If the cooling water valve is not opened, the cooling water cannot be circulated and the chiller cannot accept supply.

Solution: Open the cooling water valve to circulate it.

2.Insufficient cooling water flow or too high cooling water temperature

Both conditions hinder the heat dissipation of the refrigerant, causing the refrigerant temperature to fail to decrease, thus triggering a high-pressure alarm.

Solution: Check whether the size of the installed pipeline matches the size of the chiller. Check whether the water pump is operating normally and whether the water valve is fully open.

3.Water cooling tower failure

When the cooling tower fails, a high-pressure alarm will be triggered, causing the chiller cooling water circulation and supply to be interrupted.

Solution: Inspect the cooling tower for operational problems or defects.

4.Limescale accumulation

Water-cooled chillers that run for long periods of time without maintenance can accumulate scale and other debris on the tube walls. This accumulation hinders the efficiency of the condenser.

Solution:clean the condenser of water chiller and remove scale.

5.Excess refrigerant in water cooled chiller

Charging the system with too much refrigerant can have an effect similar to air entrapment. If too much refrigerant is added, it will not completely condense into a liquid. This excess refrigerant occupies a large part of the condenser tube, reducing the condensation effect and increasing the pressure.

Solution: Carefully drain part of the refrigerant from the low pressure side until the chiller system reaches the optimal pressure.

6.Expansion valve opening is insufficient or damaged

The expansion valve is key to converting high-pressure liquid refrigerant into a vapor state. If the valve opening is too small, high pressure will be generated at the front end of the condenser.

Solution: Gradually increase the opening of the expansion valve and reduce the pressure. If the valve is damaged, you need replace the same specification or model expansion valve .

If your chiller is with low-pressure alarms, please refer to our related low pressure alarm guide .