Blown Film Cooler: High Performance Chilled Air Solutions

1.What Is Blown Film Cooler?

A blown film cooler is a specialized type of refrigeration machine designed for use in the film blowing process. It is a cooling system that provides controlled and precise cooling air to the extrusion and forming components of a film blowing machine.

Maintaining the correct temperature is critical for achieving the desired product quality, consistency, and structural integrity. If the plastic material is too hot or too cold during the molding process, it can lead to defects in the final product. The Film Blowing chillers help ensure that the plastic material is at the optimal temperature for forming the desired shape.

A Film Blowing chiller is an essential part in the Film Blowing process, which helping to regulate temperatures and improve the quality of the final plastic products.

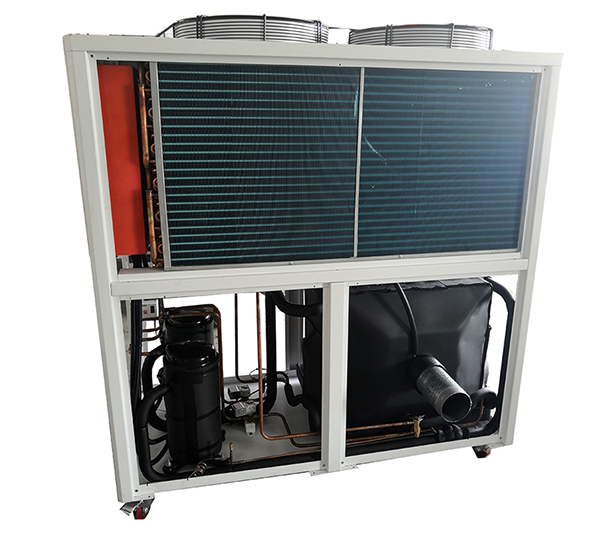

Air-cooled Blown Film Cooler

2.Why Need Air Cooler Used in Blown Film Process?

Blown film cooler, also known as bubble cooler, is a vital component in the blown film extrusion production process.

During blown film extrusion, molten plastic is forced through a circular die, forming tubular bubbles of plastic. The bubbles are then cooled and stretched to achieve the desired film thickness and properties.

The blown film cooler is responsible for rapidly cooling the extruded plastic bubbles. This is important as it helps maintain the desired performance and quality of the film. Cooling is achieved by flowing air over the surface of the bubbles. This airflow helps solidify the molten plastic, making it suitable for further processing or winding onto rolls.

APPLICABLE:

●For cooling big plastic film.

● For cooling dies.

Panasonic Compressor

Danfoss Compressor

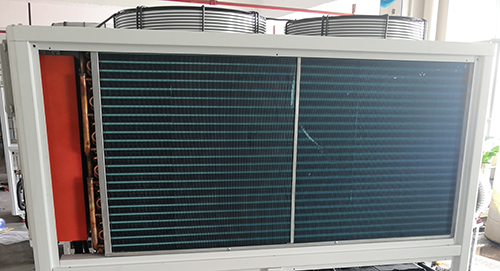

3.3 Condenser

The condenser for air-cooled Film Blowing cooler is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser for air -cooled Film Blowing chiller

3.4 Controller Panel

Air Cooler use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

● Employs Japan/Danfoss compressor for high efficiency.

● Temperature is micro-computer controlled giving convenient operation.

● LCD displayed temperature gives convenient operation.

● Easy to install and maintain.

5.How to Choose Right Air Cooler for Your Film Blowing Process?

▷ How MANY m3/H of air flow you need ?

▷ what the material for product? PE or other material ?

There are two types of chiller :Air Cooled Film Blowing Cooler and Water Cooled Film Blowing Cooler

But Most customers use air cooled Film Blowing cooler,which is more easily install and save space.

6.Get a Quote on Industrial Film Blowing Cooler Now

As a leading industrial chiller manufacturer,we engineer and produce high-quality process chillers compatible with a broad range of industrial processes.

Depending on your needs, we also offer custom chillers to ensure that each client receives the industrial chiller best suited to their unique process.

Request a quote now on our Film Blowing Cooler or learn about the other film blowing chiller we offer.