How To Choose A Water Cooling Tower For Your Water Chillers?

▷ NO Air-cooled chillers is with the fans on the top of chillers ,which absorb heat from the process water and transfer the heat to the air surrounding the chiller.They use the surrounding air of the chiller to eject the air out of the system and into the atmosphere. They consist of propeller-driven fans to pull air over the condenser‘s coils. As the air moves over the coils, heat is transferred to the air and released into the atmosphere.

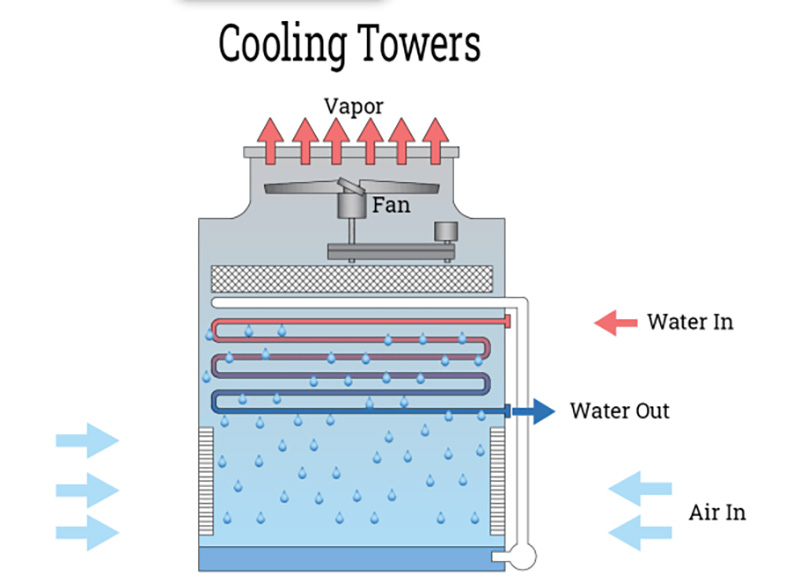

▷ Yes Water-cooled chillers use a water-cooled condenser(shell and tube condenser) connected to a cooling tower. The essential element for water cooled chillers is circulating water that comes from the cooling tower and cools the gaseous form of the refrigerant. Once the refrigerant gas is cooled, it undergoes a phase change back to a liquid and is recirculated through the system.

Water Cooled Scroll Chiller Water Cooled Screw Chiller

3.How Choose Water Cooling Tower For Your Water Cooled Chiller?

There are three important temperature factors you need to consider when choosing a cooling tower for water cooled screw chiller: inlet hot water temperature, outlet cold water temperature, and wet bulb temperature. The hot water temperature is that which enters the tower. The cold water temperature is that which leaves the water while the wet bulb temperature refers to the prevailing temperature of the geographic region where the tower is located.

Approach is the term used to refer to the difference between the temperatures of the water source as it enters the tower versus the temperature of the water once it has left the tower. This is a crucial determiner of the effective of the heat exchange process.

To choose the right cooling tower, mechanical efficiency should be given priority. This refers to the amount of fan power needed to circulate ambient air within the cooling tower. The range – or the difference in temperature between hot and cold water – is also crucial as it will impact energy usage.

so to find out how to choose a cooling water tower with sufficient cooling capacity, you should understand what circumstances require the use of a cooling tower. Please find the below water cooling tower is suitable for water cooled screw chiller :

Cooling Capacity of Chiller Water Cooling Tower Capacity

10HP(32KW/9 Ton) 20 Ton

12HP(38KW/10 Ton) 20 Ton

15HP(50KW/14 Ton) 25 Ton

20HP(66KW/18 Ton) 30 Ton

25HP(76KW/21 Ton) 40 Ton

30HP(97KW/27 Ton) 40 Ton

40HP(132KW/37 Ton) 50Ton

50HP(156KW/44 Ton) 60 Ton

60HP(197KW/57 Ton) 80 Ton

70HP(230KW/65 Ton) 80 Ton

80HP(250KW/70 Ton) 100 Ton

90HP(300KW/85 Ton) 100 Ton

100HP(350KW/100 Ton) 125 Ton

110HP(375KW/110 Ton) 125 Ton

120HP(415KW/117 Ton) 150 Ton

140HP(470KW/130 Ton) 175 Ton

160HP(500KW/140 Ton) 175 Ton

170HP(560KW/160 Ton) 200 Ton

180HP(590KW/165 Ton) 200 Ton

Water Cooling tower

4.Contact Us to Learn More About Our Water Cooling Tower

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with ooling tower.

Our probessional team will help you with any questions you have on our different kinds of cooling tower We look forward to hearing from you!