Selection Chiller Model for Injection Molding Machine or Extrusion Machine

Time:2023-10-31

Views:103

The plastics industry is one of the largest and most important industries in the world, affecting nearly every aspect of our lives, from food and medicine to entertainment and aerospace. Most plastic parts used every day are injection molded. Injection molding is a very efficient way to produce identical parts in batches with very little plastic. The injection molding machine heats the plastic pellets until they melt and then injects them into a forming mold, where the plastic parts cool. The cooling process can be lengthy; more than 80% of plastic manufacturing time is spent cooling. Injection molding chillers will significantly reduce cooling time and maintain product quality.

Here are some suggestion and tips on how to select suitable chillers models for your injection molding machine or extrusion machine. If you want to know more information ,Contact us now !

Here are some suggestion and tips on how to select suitable chillers models for your injection molding machine or extrusion machine. If you want to know more information ,Contact us now !

|

Clamping Force (Ton) |

Productivity (Kg/h) |

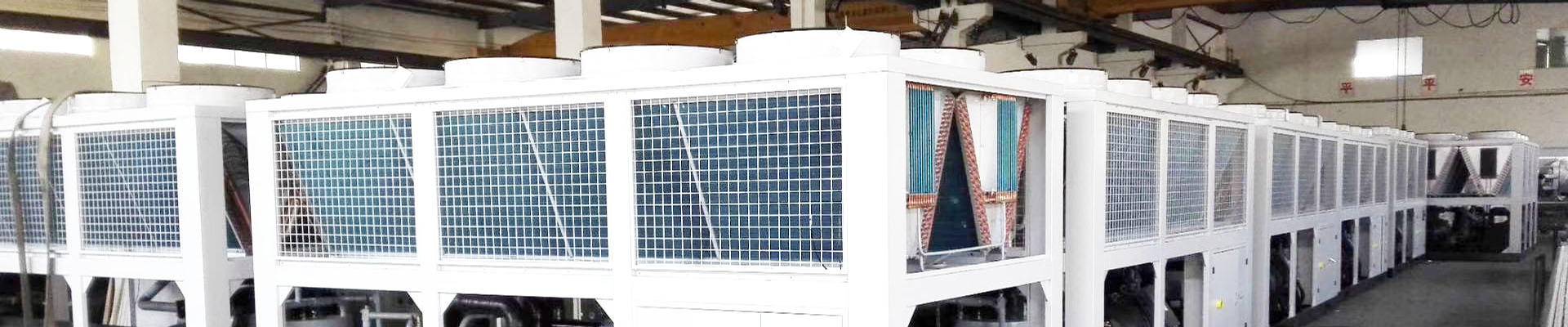

Suggest Air Cooled Chiller |

Suggest Water Cooled Chiller |

|

250 |

25 |

TW-3W |

|

|

300 |

30 |

TW-4A |

TW-4W |

|

350 |

35 |

TW-4A |

TW-4W |

|

450 |

45 |

TW-5W |

|

|

550 |

55 |

TW-8AD |

TW-8WD |

|

650 |

65 |

TW-8AD |

TW-8WD |

|

850 |

85 |

TW-10WD |

|

|

1000 |

100 |

TW-12WD |

|

|

1300 |

130 |

TW-15WD |

|

|

1500 |

150 |

TW-20WD |

|

|

1800 |

180 |

TW-20WD |

|

|

2200 |

220 |

TW-25WD |

|

|

2500 |

250 |

TW-30WT |

|

|

3000 |

300 |

TW-40WF |

|

|

4000 |

400 |

TW-50WF |

|

|

5000 |

500 |

TW-60WF |