What is An Air Cooled Chiller ? How Does Air-cooled Chiller Work?

Time:2023-10-23

Views:212

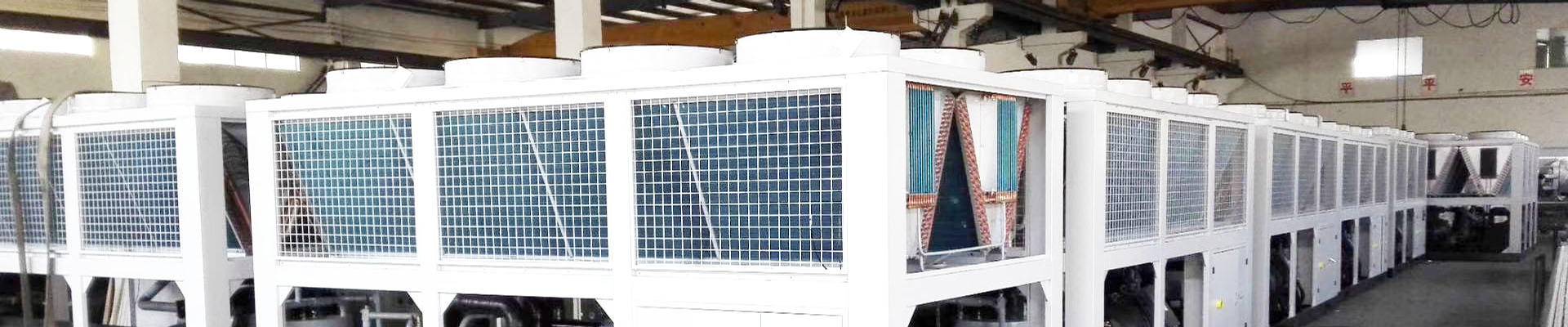

Air-cooled chillers have become an integral part of various industries and play a vital role in maintaining optimal temperature levels.Air cooled chillers are designed to remove heat from a process and release it into the surrounding air.Understanding how air0cooled chillers work and the various chiller models available will help you make the right choice to meet your cooling needs.

1.What is A Air Cooled Chiller ?

A air-cooled chiller is a refrigeration system that lowers the temperature of machinery, industrial spaces, and process fluids by removing heat from the system and transferring it elsewhere.

Air cooled chillers use a condenser similar to the "radiator" in a car. They use fans to force air through the refrigerant coils. Unless they are specifically designed for high ambient conditions, air-cooled condensers need to operate effectively at ambient temperatures of 35°C (95°F) or lower

Air-cooled chillers are essential for temperature regulation in several industrial processes such as injection molding, metal plating, medical industry ,oil field production, and food processing.

2.How Does A Air Cooled Chiller Work ?

A air-cooled chiller system consists of four basic components: compressor, condenser, evaporator and cooling process These four main components pass through copper tubes.

Compressor

A air-cooled chiller consists of a cooling circuit that comprises several key components. The process begins with the chiller‘s compressor, which compresses the refrigerant gas, raising its pressure and temperature. The high pressure gas is then transferred to the condenser.

condenser

Inside the condenser, the hot refrigerant gas is cooled by the surrounding air. The fan blows outside air over the coil containing the refrigerant, causing it to quickly dissipate heat. As a result, the refrigerant becomes a high-pressure liquid. This liquid then passes through the expansion valve.

Expansion valve and evaporator

The expansion valve controls the flow of high-pressure liquid refrigerant into the evaporator. Once inside the evaporator, the refrigerant undergoes a phase change and becomes a low-pressure gas. This phase change process absorbs heat from the process that requires cooling, effectively lowering its temperature.

cooling process

The cold gas from the evaporator is then drawn into the compressor, starting the cycle again. At the same time, the heat extracted from the process is transferred to the refrigerant gas, which is eventually released to the outdoors through the condenser. This continuous cycle of heat absorption and dissipation ensures efficient cooling of the process.

3.Basic Air Cooled Chiller Components

The air-cooled chiller components include the following:

• Condenser

• Compressor

• Evaporator

• Expansion valves

• Power unit

• Control unit

Condenser

The purpose of the chiller condenser is to remove the heat generated by the refrigerant circulating through the chiller. This is achieved by blowing cold air over the condenser ducts of air-cooled chillers.

Compressor

The compressor is the driving unit of any refrigeration system. It creates the necessary pressure gradient to push the refrigerant around the chiller to achieve process cooling. A wide variety of condensers are available, with the most popular types including centrifugal, screw, and reciprocating compressors.

Evaporators

An evaporator is placed between the expansion valves, and the condenser transfers heat from any associated processes to the circulating refrigerant. It is then sent to a cooling tower or air-cooled, depending on the chiller configuration.

Thermal Expansion Valves

The thermal expansion valve located between the compressor and evaporator is used to expand the refrigerant passing through them. This effect reduces the pressure and improves the heat dissipation effect of the evaporator.

Power Unit

Each chiller contains a power unit that controls the flow of electrical energy through the system. Power unit components typically include starters, power monitoring panels, and circuit breakers.

Control Panels

The control panel is used to regulate the entire cooling operation. They often integrate sensors, alarms and display screens, allowing operators to adjust system settings for optimal thermal control.

4.Advantages of Air-cooled Chillers

Simplicity and portability

One of the main advantages of air-cooled chillers is simplicity. Air cooled chillers do not require heavy machinery or external cooling towers, making them compact and easy to transport. With fewer components, their installation and maintenance become more straightforward, saving time and costs.

Cost-effectiveness

Because air-cooled chillers do not rely on a water source for cooling, they do not require water treatment and piping systems. This significantly reduces water-related operating costs, making air-cooled chillers a more economical choice in the long run.

Versatility

Air-cooled chillers are versatile and can be used in a variety of industries. They are easy to install and move, making them suitable for both permanent and temporary cooling solutions. Additionally, they can operate in extremely high or low ambient temperatures, providing reliable cooling in any environment.

Mastering Temperature Control: Innovative Industrial Chiller Technology

Understanding the working principles of air cooled chillers not only offers valuable insights into their operational intricacies but also highlights their profound significance. With a firm grasp of the fundamentals, both industry professionals and enthusiasts can fully appreciate how Tongwei‘s innovative technology maintains optimal temperature levels efficiently and conveniently.

Choose Tongwei for cutting-edge solutions that redefine temperature control, and experience the advantages of industrial chillers that stand as a testament to our commitment to excellence.

Contact us online for moreinformation about industria chiller and Chiller Spare Part Now.

Contact us online for moreinformation about industria chiller and Chiller Spare Part Now.