Why Your Furnace Needs A Water Chiller For Cooling

Time:2024-01-19

Views:174

If you are familiar with vacuum furnaces, you will know that vacuum furnaces have become a indispensable for industries that pursue precision, cleanliness and efficiency in material processing. However, did you know that your furnace needs a water chiller for cooling as well? In this article, we’ll talk about the reasons why your furnace needs a cooling system, and which cooling system options are available for your industrial chiller needs.

What is a vacuum furnace?

A vacuum furnace is a type of equipment specifically designed for heat treating materials under low atmospheric pressure conditions. This controlled environment eliminates the presence of oxygen and other gases, preventing oxidation and contamination of the materials being processed.

Vacuum furnaces are commonly used in the aerospace, automotive and medical industries and play a key role in producing high-quality components with precise metallurgical properties.

The role of heat and the need for cooling

In any heat treatment process, heat is the driving force. Vacuum furnaces raise temperatures to extreme levels—as much as 800 to 3000°C—facilitating processes such as annealing, brazing, sintering, and tempering.

However, as heat increases, effective cooling is required. This is where chillers come in, playing an important role in maintaining the stability and efficiency of the entire system. Keeping the process water around 100°F helps ensure that the furnace walls remain below a safe temperature of 150°C.

Why Your Vacuum Furnace Needs a Chiller For Cooling

Firstly, let‘s take a look at why it‘s essential to have an industrial chiller for your furnace. For starters, furnace chillers help maintenance and prolong equipment life. A chiller circulates coolant through the furnace to remove excess heat from the equipment. This prevents overheating, which can damage the furnace‘s internal parts, lower the efficiency of the machine, or even lead to a complete breakdown. As such, having a chiller installed is one of the most proactive moves one can make regarding furnace operation.

Another reason why your furnace needs a chiller is the effects of environmental factors. If the temperature outside is high, this can adversely affect the operation of the furnace. The chiller circulates air through the equipment, removing excess heat and ensuring that it runs as expected. By adding a chiller for cooling, you will maintain a consistent performance of your furnace regardless of the external temperature.

Types of Vacuum Furnace Chiller

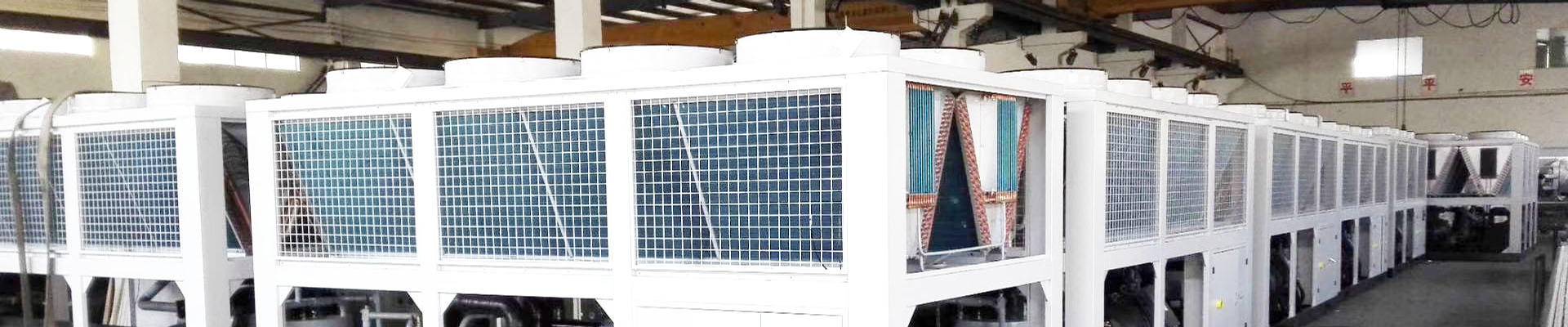

When discussing vacuum furnace chiller,there are two types: air-cooled and water-cooled chiller.

air-cooled vacuum furnace chillers require less space, are less expensive to install and operate, and are more practical for smaller machines where water is not present.

Water-cooled vacuum furnace chillers are more efficient and require less maintenance than air-cooled options. However, they need to be connected to a water cooling tower or other water source and consume more energy.Ultimately, the choice between water-cooled and air-cooled chiller for your furnace is dependent on the specific cooling requirement and the size of the furnace.

Installing a chiller is critical for any furnace owner, and the choice of chiller type depends on the specific equipment and cooling requirement. Air cooled chillers are more practical for smaller machines or where water may not be available, while water cooled chillers are for larger equipment where water supply is readily available. Regardless, a industrial chillers help in extending the operating life of the furnace and maintaining peak performance.

To conclude, adding a cooling system to your furnace is a vital investment that guarantees optimal performance. As industrial chiller professionals, we can assist you in choosing the best cooling system for your furnace. Contact us today, and let us improve your furnace‘s performance, save energy and prolong the lifespan of your equipment.