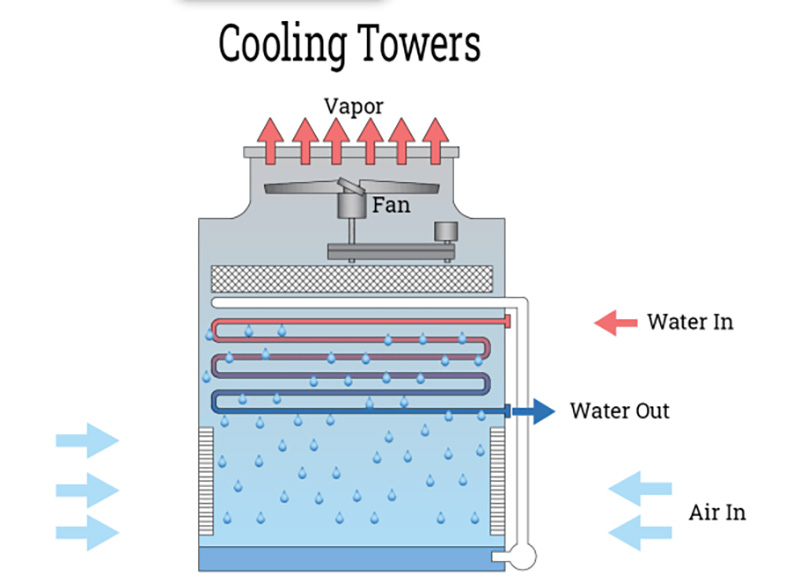

Air conditioning equipment and industrial processes generate large amounts of hot water that need to be cooled. This is where industrial cooling towers come in. The superheated water passes through a cooling tower where it is recirculated and exposed to cool, dry air. Heat leaves the circulating cooling tower water through evaporation.

This is called evaporative cooling. The cooler water then re-enters the air conditioning unit or process to cool the unit, and the cooling cycle repeats over and over again. When the hot condenser enters the cooling tower, the water passes through some nozzles that spray the water into small droplets, which increases the surface area of the water and allows for better heat loss through greater evaporation.

The function of the fan at the top of the water-cooling tower is to bring in the air at the bottom of the tower and move it upward in the opposite direction to the warm condensation water at the top of the unit. The air will carry heat through the evaporation of water from the cooling tower into the atmosphere.

Industrial machines and processes that generate large amounts of heat must be constantly cooled so that these machines can continue to operate efficiently. The most effective, efficient and cheapest solution to remove this heat is to install an industrial cooling tower.

5.Components of a Cooling Tower

The Frame and Casing: This is the tower’s structure, usually made of robust material like metal or fiberglass.

The Fill: This is where the action happens. The fill increases the contact area between the air and the water.

The Cold Water Basin: This collects the cooled water at the bottom of the tower, where it’s sent back to cool the industrial process.

The Drift Eliminators: These guys capture water droplets that could be carried away with the escaping air.

The Fans: They draw air through the tower, aiding the evaporation process.

6.Types of Water Cooling Towers

Not all towers are suitable for all applications. Water cooling towers are designed and manufactured in several types and are available in many sizes. When determining the right tower for a project, it is important to understand the various types and their advantages and limitations. Under certain water treatment conditions, the cooling effect is one of the important performances of the cooling tower. When selecting a water cooling tower, the main consideration is whether there are special requirements for cooling degree, cooling water volume, and wet bulb temperature. It is usually installed in a place with good ventilation.

According to the flow direction of hot water and air, there are cross-flow (AC) cooling towers and counter-flow cooling towers.

Crossflow Cooling Towers

In crossflow cooling towers the water flows vertically through the fill while the air flows horizontally, across the flow of the falling water.

It is commonly used in residential areas with strict noise requirements, and is the most commonly used cooling circulation tower in the air conditioning industry.

Energy saving, low water pressure, small wind resistance, low-speed motor, no dripping noise and wind noise, easy maintenance of filling and water distribution system.

It should be noted that the frame needs 40% more filler volume when exchanging heat. The filler is easy to age, the water distribution holes are easy to be blocked, the anti-icing is not good, and the moisture backflow is large. The advantages of cross-flow towers are exactly the disadvantages of counter-flow towers.

Counterflow Cooling Towers

Counterflow cooling towers are designed so that air flows vertically upward, opposing the flow of water descending through the fill.

Because of this vertical air flow, it is not possible to use the open gravity flow basins typical of cross-flow designs. In contrast, counterflow towers use a pressurized, pipe-type spray system to spray water onto the top of the packing.

Since air must be able to pass through the spray system, the distance between the ducts and nozzles must be further apart to avoid restricting airflow.

Round Tyoe Counterflow Cooling Towers

According to circulating water circuit, there are open type water cooling tower and closed type water cooling tower

Open Type Cooling Tower

By spraying circulating water onto the glass fiber filler, heat exchange is achieved through the contact between water and air, and then a fan drives the air flow in the tower to circulate, taking out the hot air flow after exchanging heat with the water, thereby achieving cool down.

Closed Type Cooling Tower

▷ The closed cooling tower has a fully closed circulation of cooling medium, which can prevent debris from entering the cooling pipeline system and evaporation loss of the cooling medium.

▷ Use soft water as the cooling medium, no scaling, no clogging of pipelines, and fewer failurs.

▷ Adopting dual cooling methods of air cooling and spray water evaporation and heat absorption, the cooling efficiency is high.

▷ The device is small in size, takes up little space, is easy to move and place, and does not require the construction of a pool.

▷ Using automated intelligent control, the cooling mode can be automatically changed according to working conditions, and the operation is simple and reliable.

▷ It has a wide range of uses and can directly cool quenching liquid, oil, alcohol and other media that have no corrosive effect on the heat exchanger. The medium has no loss and has stable composition.

7.Cooling Tower Efficiency and Maintenance

Proper maintenance is key to optimizing cooling tower efficiency and extending cooling tower life. This includes routine inspections, repairs and preventive measures to detect and resolve potential problems early. Here is an overview of the various steps involved in cooling tower maintenance.

Regular cleaning

Keeping your cooling tower clean is critical to its optimal operation. This includes cleaning the pool to remove any sediment and prevent algae growth, which can block water flow and reduce cooling efficiency. Additionally, the filling media within the tower should be kept clean to ensure maximum air-water contact.

Water treatment

The quality of cooling tower water directly affects the performance of the cooling tower. Regular water treatment, including the use of biocides, algicides, and antiscalants, can prevent problems such as corrosion, scaling, and biological growth that can damage cooling towers and reduce their efficiency.

Mechanical component inspection

The mechanical parts of the cooling tower, such as fans, motors, belts, etc., need to be checked regularly for signs of wear. Prompt replacement or repair of these components can prevent failures and maintain tower performance.

Monitor cooling tower performance

Regular performance monitoring is critical to ensuring your cooling tower is operating as efficiently as possible. This includes tracking key parameters such as water flow rate, air flow rate and cooling capacity. Any significant changes in these parameters may indicate a problem that requires immediate attention.

Seasonal preparations

Because cooling towers are exposed to the elements, they need to be prepared for different seasons. For example, it is crucial to properly winterize cooling towers before winter sets in. Instead, preparing for summer involves ensuring cooling towers can handle the higher loads associated with warmer weather.

8.Contact Us to Learn More About Our Water Cooling Tower

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with ooling tower.

Our probessional team will help you with any questions you have on our different kinds of cooling tower We look forward to hearing from you!