Explosion-Proof & Hazardous Process Chiller

Explosion proof & hazardous process chiller is a specially designed refrigeration machine that used in hazardous environments with flammable substances and laboratories handling volatile materials,which withstand rugged and dangerous environments.Tongwei explosion-proof chillers are built for demanding applications, including food, pharmaceuticals, biotechnology, chemicals, nuclear science, and more.

Explosion-Proof chiller is with air-condenser and water-condenser from 1/2 ton to 200 ton cooling capacity,it uses explosion-proof water pump,fan and electrical box,hermetic scroll Panasonic/Danfoss compressors using environmental friendly R410A/R407C refrigerant.The evaporator is stainless steel coil in water tank or shell and tube /stainless steel plate type .

Our custom, explosion-proof chillers are built to meet specific regulations and NEC Class Divisions. All explosion-proof chillers are custom built to your order and can meet Class 1 Division 1 and Class 1 Division 2. We offer chiller options in various capacities to meet your facility needs.

Air Cooled Explosion proof Chiller

1.What is An Explosion-Proof Chiller?

An Explosion Proof Chiller is a particularly chiller unit that installed in harsh or explosive industrial applications,so it is with reinforced design to protect the chiller’s components from ambient flammable materials that could cause an explosion.

The explosion proof chiller must be sealed wiring to protect the air from stray sparks that could ignite any vapors or flammable gases. Chillers utilized within hazardous environments must have adequate physical protection and special safety features built-in to prevent damage to sensitive components.Adhering to these guidelines and fulfilling our customers’ needs require us to custom-design many of our explosion-proof chillers.

2.Why Explosion-Proof Chillers Are So Important

In order to protect the safety of employees and facilities, reducing the likelihood of explosions becomes the primary goal of any business owner. Some work-sites are more dangerous than others. Reduce the risk that sparks from the chiller could ignite explosive or flammable materials, which is why explosion-proof chiller is a safety requirement in many industries. Although the price of all explosion-proof equipment is high, the cost is far less than the loss of life caused by industrial accidents due to the use of the wrong machinery.

In addition to safety concerns, explosion-proof chillers are required by law in many locations where with combustible materials in the air. In addition to the danger of igniting flammable substances, non-compliance could result in huge emissions.

3.How Does an Explosion-Proof Chiller Work?

There are many types of explosion-proof chillers, and how each one works depends on the components used. For example, there are screw and scroll compressors, air-cooled and water-cooled condensers. The components of the chiller system are not explosion-proof. The design of the entire system. But these components determine the ultimate efficiency of the chiller and the temperatures it can reach. Use this information when choosing a chiller for your workplace.

Most chillers operate in the same way, in short, by continuously flowing refrigerant to the cold end of the evaporator at the desired temperature. The chiller then pumps the cooled fluid through the process to dissipate heat from the equipment and funnel it back to the return side. The range of chiller we choose is -60 F to 30 F. If you have any special requirements for the cooling of chiller, please contact us .

The refrigerant starts the process in a mixture of liquid and gas. The gas and liquid enter the evaporator, where the heat converts the refrigerant into a low-pressure gas. This gas enters a compressor, which compresses the gas to a high pressure state using one of several methods. This gas moves to the condenser, which can cool the refrigerant with water or air. In a condenser, the coolant releases heat and condenses into a liquid. When the liquid is at high pressure as it passes through the expansion valve, the expansion valve controls how much cooled refrigerant enters the evaporator and starts the cycle again.

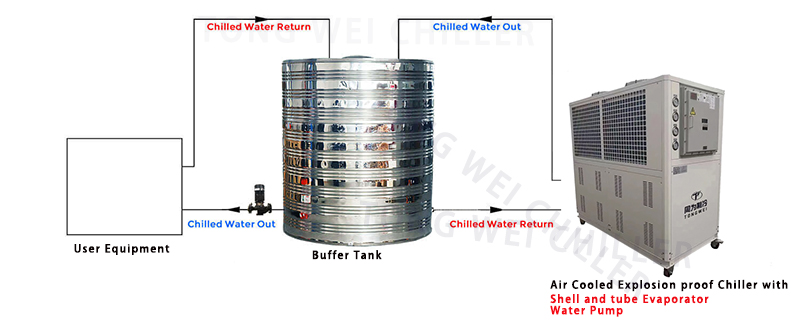

Air-Cooled Explosion Proof Chiller Installation

Water-Cooled Explosion Proof Chiller Installation

4.Types of Explosion-Proof Chillers

20HP Air-Cooled Scroll Explosion Proof Chiller 30HP Water-Cooled Scroll Explosion Proof Chiller

5.What Are The Main Components of Explosion-proof Chillers?

Above 60HP(50 Ton) explosion proof chiller , which is with Hanbell or Bitzer brand Screw compressor ,

These brand compressors are with high refrigeration efficiency,low noise ,energy saving,environmental protection and durability,safety and stability.

Panasonic Compressor

Danfoss Compressor

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

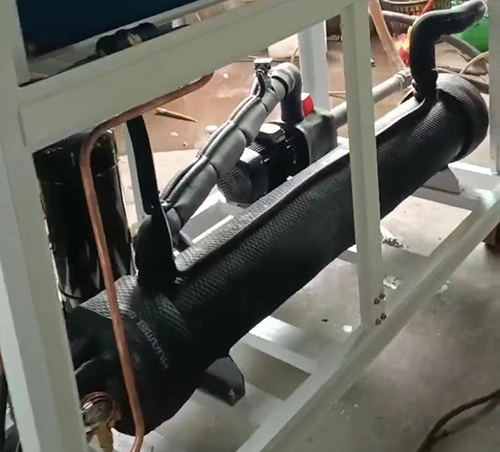

Shell and Tube Evaporator

5.3 Water Pump

The water pump for explosion proof chiller is explosion-proof .

Explosion Proof Water Pump

5.4 Condenser

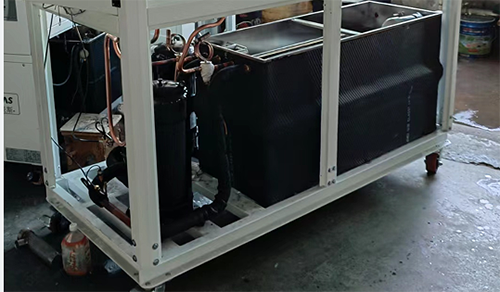

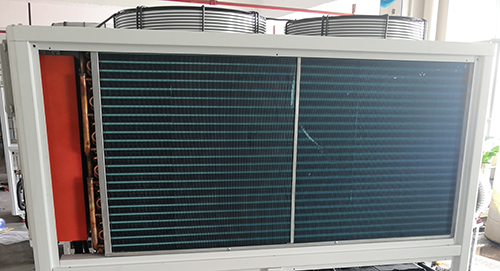

The condenser for air cooled explosion chiller is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability. The fan on the top of explosion proof chiller is also explosion proof .

Aluminum fin+fan Condenser for explosion proof chiller

The condenser for water-cooled explosion proof chiller is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser for water-cooled explsoion proof chiller

5.5 Electric Box

The electric box for chiller is also explosion proof .

Explosion Proof Electric Box

Chemical Plants

7.Contact Us to Learn More About Our Explosion-Proof Chillers

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with explosion proof chiller. Contact us today for more information on a explosion-proof chiller.

Our probessional team will help you with any questions you have on our explosion proof chiller units. We look forward to hearing from you!