|

Content

2.1 Compressor

2.2 Evaporator

2.3 Water Pump

2.4 Condenser

2.5 Controller Panel

4.1 Power

4.2 Water Pump

4.3 Refrigerant

4.4 Evaporator Choose

|

12 Ton Air Cooled Process Chiller

12 Ton Indsutrial Air Cooled Process Chiller

1.How Does An Air-cooled Chiller Work?

2.What Are The Main Components Of Industrial Air Cooled Process Chiller ?

Panasonic Compressor

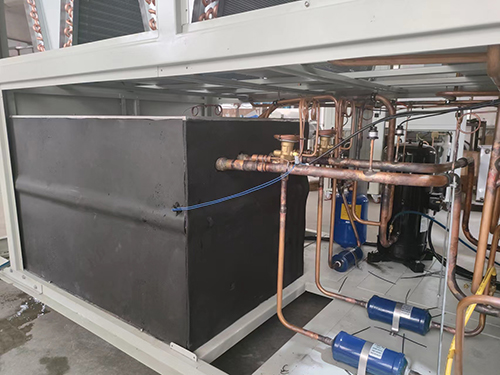

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

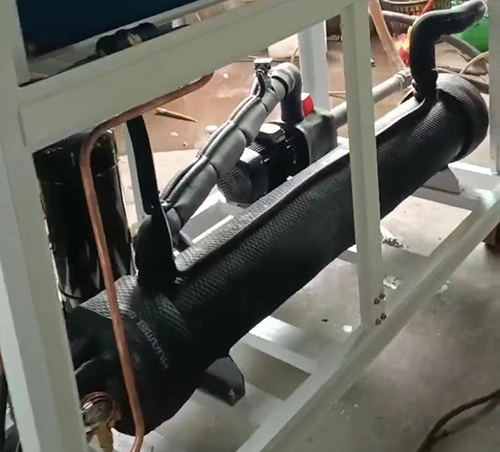

Shell and Tube Evaporator

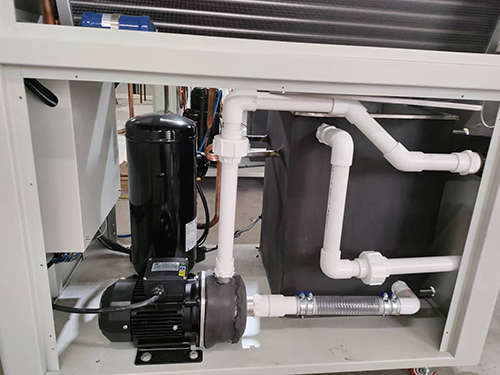

2.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

the water pressure water pump for chiller is about 2 bar , but if you need more higher water pressure , pls tell us when you inquiry .For example ,when you use chillers for cooling bottle blowing machine ,the water pressure for water pump need about 4 bar .

Water Pump

High Pressure Water Pump

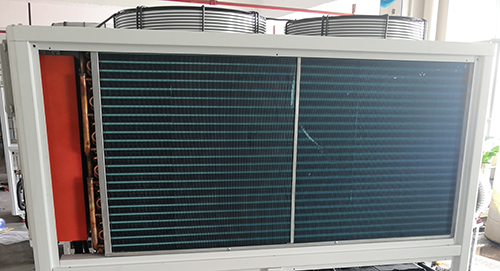

2.4 Condenser

The condenser for industrial air cooled chiller is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser

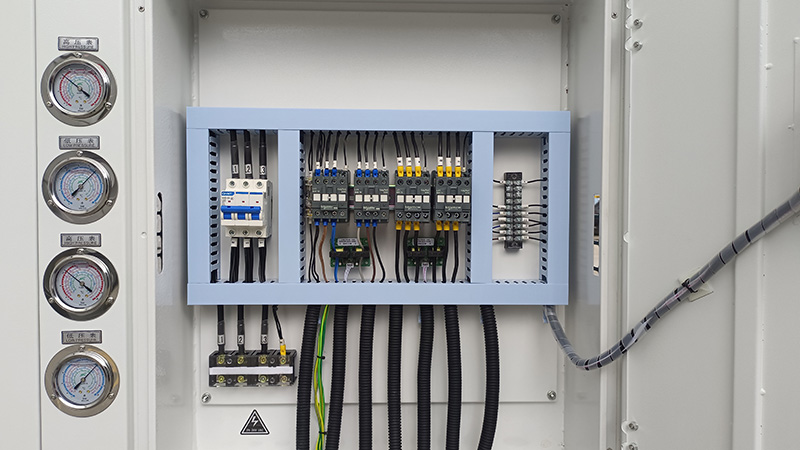

2.5 Controller Panel

Tongwei chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

3. What Applications Does A Process Chiller Used in?

There are endless uses for process chillers due to their flexibility and the need for cooling for many processes. For a product to meet its designed requirements, it must be produced at a specific temperature so that the method of production does not alter its properties. Process chillers cool both products and machinery during production.

Food Processing

Refrigeration is a vital part of the preservation and stability of foods and is the most common application for which cooling is required. Additionally, chillers are used in food production to ensure that products are kept at a constant temperature, especially in producing alcoholic beverages that temperature fluctuations can severely damage.

Process Chiller In Food Industry

Metal Plating

Process Chiller in metal plating industry involves high-temperature electroplating or electroless plating,which remove the heat from each process very high temperatures.The exceptionally high temperatures and harsh conditions demand the use of process chiller that is resilient enough to withstand these conditions

Plastic Production

Plastic production is a process that requires the most precise and accurately controlled temperatures to avoid producing damaged or inferior products. The process has little margin for error since intense and elevated heat can melt the plastic and destroy a production run. Although the molds for plastic production do not have to achieve exceptionally high temperatures, their continual use requires that they remain heated for several hours.

In the case of extruded plastics, the extruded plastic has to be cooled in a bath at exactly the correct temperature. The bath water must also be circulated and cooled at each run. For cast plastic and extruded plastic, process chillers provide the necessary temperature control to ensure the quality of the products produced.

Injection Molding Chillers

The plastics industry is one of the largest and most important industries in the world, affecting nearly every aspect of our lives, from food and medicine to entertainment and aerospace. The majority of plastic parts used everyday are injection molded. Injection molding is an extremely effective way to mass produce identical components with very little waste material. An injection molding machine heats plastic particles until they become molten and then injects them into a shaped mold where the plastic part cools. The cooling process can be very lengthy; over 80% of the total plastic manufacturing time is devoted to cooling. An injection molding chiller will drastically reduce the cooling time and preserve the quality of your products.

INJECTION MOLD CHILLER SOLUTIONS

The cooling process varies depending upon the size, thickness, and type of plastic used. Using a water cooled injection molding chiller to cool the mold cavity will not only help reduce the duration of the process, but can improve the quality of the plastic. If cooled incompletely, the plastic in the mold can warp and deform when it is ejected from the mold, causing costly mistakes.

Tongwei is the best industrial plastic chillers and liquid coolers to consistently and efficiently maintain the quality of your plastic parts and reduce your production time.

4 .How I Can Choose The Right Chiller?

There are four important chiller specifications you need consider when you choose a chiller for your application :the voltage required for operation, the associated pump horsepower and flow rate (contact us for custom selection), refrigerant, and the evaporator type.

4.1 Power

Different countries and regions have different standards for industrial electricity, the common power supplies are 208-230V, 380-420V,440-480V,50Hz or 60Hz, 3phase.

Such in Philippines ,the power supply is 220V 60HZ 3PH , 380V 60HZ 3PH ,460V 60HZ 3PH;

in Singapore and Malaysia ,the power supply is 415V 50HZ 3PH;

in Mexico ,the power supply is 220V 60HZ 3PH;

In USA ,the power supply is 208V 60HZ 3PH;575V 60HZ 3PH;480V 60HZ 3PH and so on

4.2 Water Pump

When you decide the capacity/tonnage of the chiller, we will recommend you the suitable pump in KW,which standard water pump is about 2 bar .If you need more high water pressure , please us when you inquiry.

4.3 Refrigerant

R22, R410A, R407C, R404A, R134A are optional choices.

R22: good cooling effect, but R22 is considered a powerful greenhouse gas, so it’s forbidden in most countries.

R410A: eco-friendly, R-410A has replaced R-22 as the preferred refrigerant for use in residential and commercial air conditioners in Japan, Europe, and the United States. R-410A operates at higher pressures than other refrigerants.

R407C: a good replacement for R22, good cooling effect.

R404A: suitable for application that requires low temperature(below -10°c).

R134A: a non-flammable gas used primarily as a “high-temperature” refrigerant, suitable for air-cooled chiller working at a high ambient temperature above 50℃.

4.4 Evaporator Choose

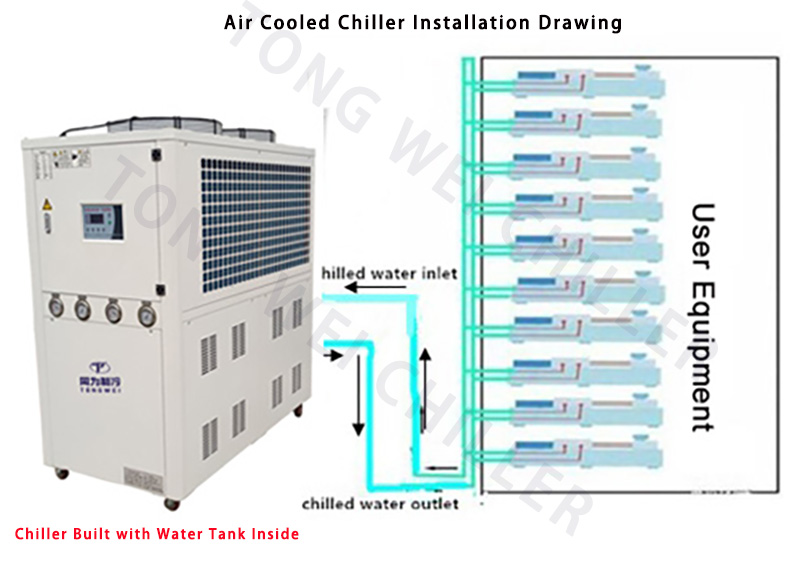

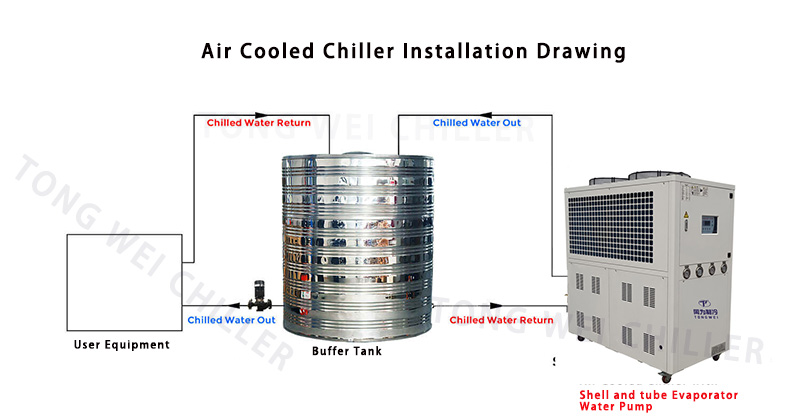

Chillers generally have two types of evaporators: one is coil in water tank evaporator ,the other one is shell and tube evaporator.

Coil and tank evaporator, which has a built-in water storage tank for more convenient use,so there’s no need for extra buffer tanks. This is also our standard evaporator for chiller , if you don’t have buffer tank ,we just use this evaporator for your chiller.(See Above 2.2)

Shell and tube type evaporator, which requires an additional water buffer tank to connect .(See Above 2.2)

5.Contact Us to Learn More About Our Industrial Air-cooled Proces Chiller Chillers

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with an industrial air cooled process chiller unit. Contact us today for more information on a industrial air cooled chiller unit.

Our probessional team will help you with any questions you have on our industrial air cooled chiller units. We look forward to hearing from you!