Industrial Water Cooled Process Chiller Unit

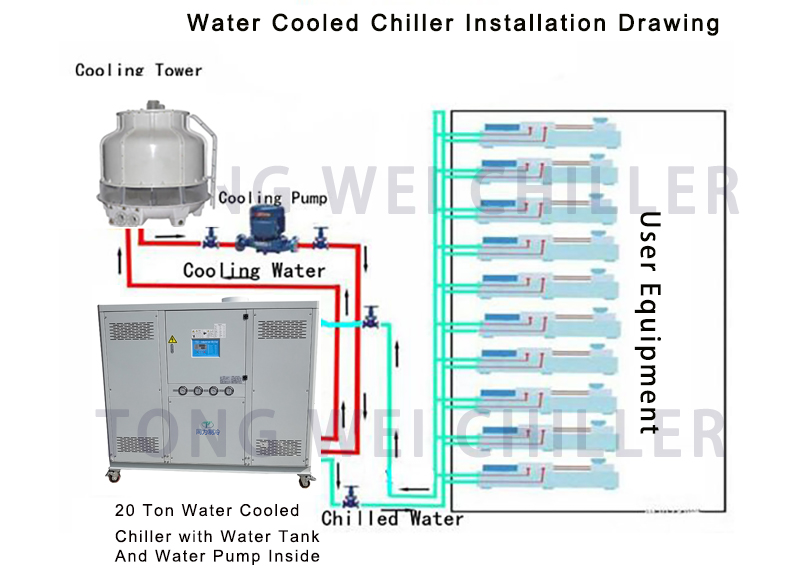

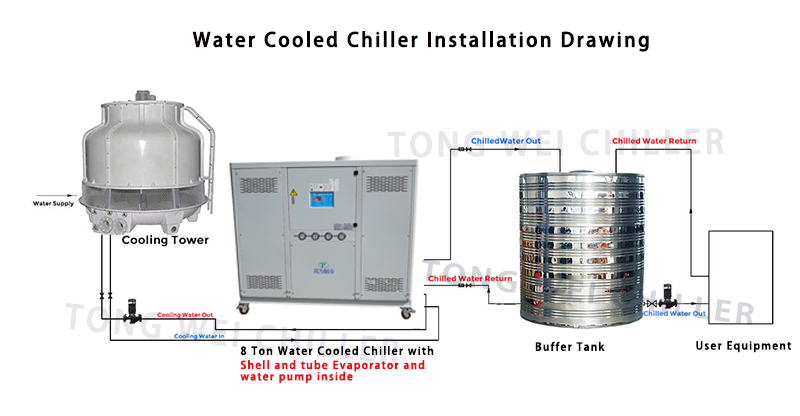

Industrial water cooled process chiller unit is a refrigeration system also called packaged chiller that used in control the cooling (direct or indirect) of products, mechanisms, and machinery in a variety of industrial processes.A water cooled process chiller is equipped with a water-cooled condenser that uses water from a water cooling tower to cool the refrigerant gas. After the refrigerant is cooled and released via an extension valve, it will cool down the water that circulates in the chiller and reach the low temperature that user needs. In other words, the processed water works as a medium for heat transfers.

Our water cooled process chiller with a standard capacity of 3 tons to 60 tons circulate a fluid medium between 5℃ - 35 ℃. The chillers manufactured by Tongwei including multi-stage hermetic Panasonic/Danfoss scroll compressor using R410A/R407C refrigerant,large capacity stainless steel water tank and water pump

1.How Does Industrial Water Cooled Process Chiller Unit Work?

2.What Are The Main Components Of Industrial Water Cooled Process Chiller Unit?

2.1 Compressor

The compressor is the key mover in industrial water cooled process chiller unit because it produces pressure variations to stir the refrigerant around,which is with Panasonic or Danfoss brand compressor, using R410A/R407C refrigerant,this brand compress is with high refrigeration efficiency,low noise ,energy saving,environmental protection and durability,safety and stability.

Panasonic Compressor

Danfoss Compressor

2.2 Evaporator

The evaporator is a crucial component of industrial water cooled process chiller unit, as it is responsible for extracting heat from the liquid being cooled,it is located between the compressor and the expansion valve. There are three types of evaporators : coil in water tank evaporator , shell and tube evaporator, 304SS stainless steel plate type evaporator.

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

Shell and Tube Evaporator

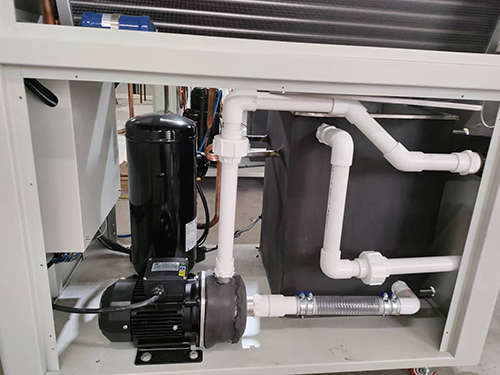

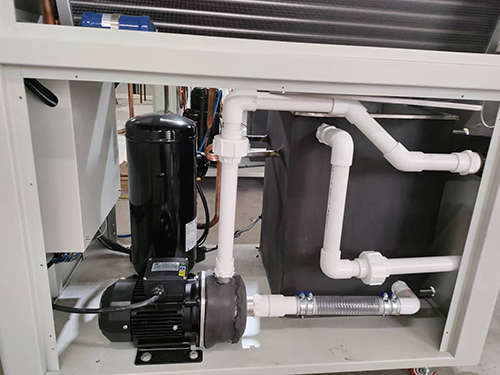

2.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

the water pressure water pump for chiller is about 2 bar , but if you need more higher water pressure , pls tell us when you inquiry .For example ,when you use chillers for cooling bottle blowing machine ,the water pressure for water pump need about 4 bar .

Water Pump

High Pressure Water Pump

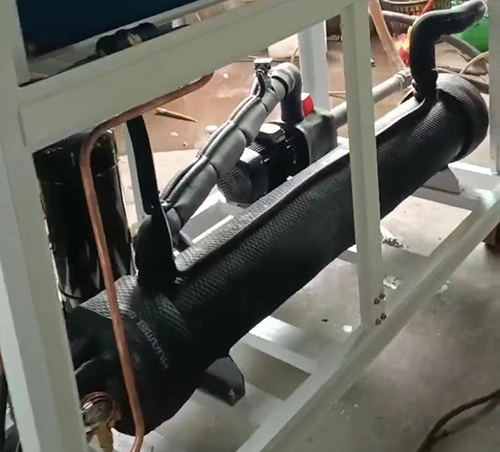

2.4 Condenser

The condenser for industrial water cooled process chiller is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser

2.5 Controller Panel

Tongwei chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

Standard Features For Industrial Water Cooled Process Chiller Unit:

▪ Low vibration and noise Panasonic/Danfoss scroll compressor

▪ Stainless steel Coil/brazed plate evaporator with copper pipe

▪ Extra-large stainless-steel Water reservoir

▪ Stainless steel pump

▪ Solenoid Valve

▪ Aluminum tank level gauge with built in thermometer

▪ Pump motor solid state overload protection

▪ Oversized refrigerant filter/drier

▪ Cleanable air inlet filters

▪ Factory tested prior to shipment.

4. How I Can Choose The Right Industrial Water Cooled Process Chiller Unit?

There are four important chiller specifications you need consider when you choose a chiller for your application :the voltage required for operation, the associated pump horsepower and flow rate (contact us for custom selection), refrigerant, and the evaporator type.

4.1 Power

Different countries and regions have different standards for industrial electricity, the common power supplies are 208-230V, 380-420V,440-480V,50Hz or 60Hz, 3phase.

Such in Philippines ,the power supply is 220V 60HZ 3PH , 380V 60HZ 3PH ,460V 60HZ 3PH;

in Singapore and Malaysia ,the power supply is 415V 50HZ 3PH;

in Mexico ,the power supply is 220V 60HZ 3PH;

In USA ,the power supply is 208V 60HZ 3PH;575V 60HZ 3PH;480V 60HZ 3PH and so on

4.2 Water Pump

When you decide the capacity/tonnage of the chiller, we will recommend you the suitable pump in KW,which standard water pump is about 2 bar .If you need more high water pressure , please us when you inquiry.

4.3 Refrigerant

R22, R410A, R407C, R404A, R134A are optional choices.

R22: good cooling effect, but R22 is considered a powerful greenhouse gas, so it’s forbidden in most countries.

R410A: eco-friendly, R-410A has replaced R-22 as the preferred refrigerant for use in residential and commercial air conditioners in Japan, Europe, and the United States. R-410A operates at higher pressures than other refrigerants.

R407C: a good replacement for R22, good cooling effect.

R404A: suitable for application that requires low temperature(below -10°c).

R134A: a non-flammable gas used primarily as a “high-temperature” refrigerant, suitable for air-cooled chiller working at a high ambient temperature above 50℃.

4.4 Evaporator Choose

Chillers generally have two types of evaporators: one is coil in water tank evaporator ,the other one is shell and tube evaporator.

Coil and tank evaporator, which has a built-in water storage tank for more convenient use,so there’s no need for extra buffer tanks. This is also our standard evaporator for chiller , if you don’t have buffer tank ,we just use this evaporator for your chiller.

Shell and tube type evaporator, which requires an additional water buffer tank to connect .

5.How Choose Water Cooling Tower For Your Industrial Water Cooled Process Chiller Unit?

There are three important temperature factors you need to consider when choosing a cooling tower for industrial water cooled process chiller unit: inlet hot water temperature, outlet cold water temperature, and wet bulb temperature. The hot water temperature is that which enters the tower. The cold water temperature is that which leaves the water while the wet bulb temperature refers to the prevailing temperature of the geographic region where the tower is located.

Approach is the term used to refer to the difference between the temperatures of the water source as it enters the tower versus the temperature of the water once it has left the tower. This is a crucial determiner of the effective of the heat exchange process.

To choose the right cooling tower, mechanical efficiency should be given priority. This refers to the amount of fan power needed to circulate ambient air within the cooling tower. The range – or the difference in temperature between hot and cold water – is also crucial as it will impact energy usage.

so to find out how to choose a cooling water tower with sufficient cooling capacity, you should understand what circumstances require the use of a cooling tower. Please find the below water cooling tower is suitable for water cooled screw chiller :

Cooling Capacity of Chiller Water Cooling Tower Capacity

5HP(16KW/4 Ton) 15 Ton

6HP(19KW/5 Ton) 15 Ton

8HP(25KW/7 Ton) 20 Ton

10HP(30KW/8 Ton) 20 Ton

12HP(40KW/11 Ton) 25 Ton

15HP(50KW/14 Ton) 25Ton

20HP(65KW/18 Ton) 30 Ton

25HP(80KW/22 Ton) 40Ton

30HP(100KW/28 Ton) 40 Ton

40HP(130KW/37 Ton) 50 Ton

50HP(153KW/43Ton) 60 Ton

60HP(200KW/56 Ton) 80 Ton

Water Cooling Tower

5.Which Industries Need An Industrial Water Cooled Process Chiller Unit?

Water chillers are used in various industries. Some of them include the following:

▪ Plastic manufacturing and processing

▪ Metal forming

▪ Food and beverage processing

▪ Machinery

▪ Chemical & pharmaceutical

▪ Medical (MRI, CT scanner, x-ray, linear accelerator, laboratory)

▪ Laser cutting

▪ Transportation manufacturing

▪ Semiconductor

▪ Composite manufacturing.

6.What is the Difference Between Industrial Air Cooled Process Chiller Unit and Industrial Water Cooled Process Chiller Unit?

The main difference between industrial air cooled process chiller unit and industrial water cooled process chiller unit is condenser :

The condenser of an industrial air cooled process chiller unit is cooled by the ambient air,which the heat generated during the cooling process is dissipated into the surrounding air;

Industrial water cooled process chiller unit with a shell and tube water-type condenser that is attached to a cooling tower and is typically used in medium and wide installations where water is available.So industrial Water cooled chiller need connect with water cooling tower and water cooling pump outside , the installation is more trouble than air cooled screw chiller .

But if your ambient temperature is very high above 50℃,we suggest you use industrial water cooled process chiller ,as industrial air cooled process chiller may consume more energy to achieve the same cooling capacity due to the limitations of air as a heat exchange medium and industrial water cooled chiller uses constant water source for more stable and efficient heat dissipation,so in high ambient temperature , industrial water cooled chiller is more energy-efficient and better choice for your application .

20 Ton Air Cooled Process Chiller

7.Contact Us to Learn More About Our Industrial Water Cooled Process Chiller Unit

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with an industrial water-cooled process chiller unit. Contact us today for more information on an industrial water cooled process chiller unit.

Our probessional team will help you with any questions you have on our water-cooled process chiller units. We look forward to hearing from you!

Panasonic Compressor

Danfoss Compressor

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

Shell and Tube Evaporator

2.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

the water pressure water pump for chiller is about 2 bar , but if you need more higher water pressure , pls tell us when you inquiry .For example ,when you use chillers for cooling bottle blowing machine ,the water pressure for water pump need about 4 bar .

Water Pump

High Pressure Water Pump

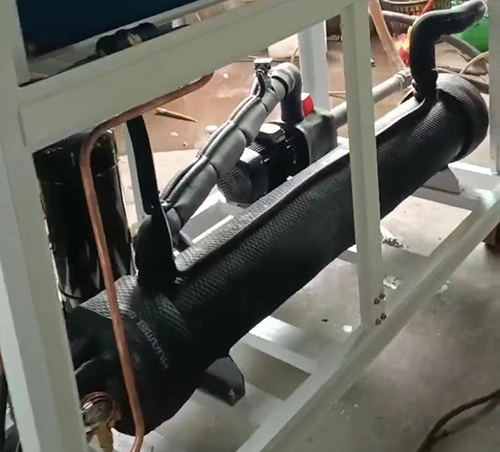

2.4 Condenser

The condenser for industrial water cooled process chiller is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser

2.5 Controller Panel

Tongwei chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

Standard Features For Industrial Water Cooled Process Chiller Unit:

▪ Low vibration and noise Panasonic/Danfoss scroll compressor

▪ Stainless steel Coil/brazed plate evaporator with copper pipe

▪ Extra-large stainless-steel Water reservoir

▪ Stainless steel pump

▪ Solenoid Valve

▪ Aluminum tank level gauge with built in thermometer

▪ Pump motor solid state overload protection

▪ Oversized refrigerant filter/drier

▪ Cleanable air inlet filters

▪ Factory tested prior to shipment.

4. How I Can Choose The Right Industrial Water Cooled Process Chiller Unit?

There are four important chiller specifications you need consider when you choose a chiller for your application :the voltage required for operation, the associated pump horsepower and flow rate (contact us for custom selection), refrigerant, and the evaporator type.

4.1 Power

Different countries and regions have different standards for industrial electricity, the common power supplies are 208-230V, 380-420V,440-480V,50Hz or 60Hz, 3phase.

Such in Philippines ,the power supply is 220V 60HZ 3PH , 380V 60HZ 3PH ,460V 60HZ 3PH;

in Singapore and Malaysia ,the power supply is 415V 50HZ 3PH;

in Mexico ,the power supply is 220V 60HZ 3PH;

In USA ,the power supply is 208V 60HZ 3PH;575V 60HZ 3PH;480V 60HZ 3PH and so on

4.2 Water Pump

When you decide the capacity/tonnage of the chiller, we will recommend you the suitable pump in KW,which standard water pump is about 2 bar .If you need more high water pressure , please us when you inquiry.

4.3 Refrigerant

R22, R410A, R407C, R404A, R134A are optional choices.

R22: good cooling effect, but R22 is considered a powerful greenhouse gas, so it’s forbidden in most countries.

R410A: eco-friendly, R-410A has replaced R-22 as the preferred refrigerant for use in residential and commercial air conditioners in Japan, Europe, and the United States. R-410A operates at higher pressures than other refrigerants.

R407C: a good replacement for R22, good cooling effect.

R404A: suitable for application that requires low temperature(below -10°c).

R134A: a non-flammable gas used primarily as a “high-temperature” refrigerant, suitable for air-cooled chiller working at a high ambient temperature above 50℃.

4.4 Evaporator Choose

Chillers generally have two types of evaporators: one is coil in water tank evaporator ,the other one is shell and tube evaporator.

Coil and tank evaporator, which has a built-in water storage tank for more convenient use,so there’s no need for extra buffer tanks. This is also our standard evaporator for chiller , if you don’t have buffer tank ,we just use this evaporator for your chiller.

Shell and tube type evaporator, which requires an additional water buffer tank to connect .

5.How Choose Water Cooling Tower For Your Industrial Water Cooled Process Chiller Unit?

There are three important temperature factors you need to consider when choosing a cooling tower for industrial water cooled process chiller unit: inlet hot water temperature, outlet cold water temperature, and wet bulb temperature. The hot water temperature is that which enters the tower. The cold water temperature is that which leaves the water while the wet bulb temperature refers to the prevailing temperature of the geographic region where the tower is located.

Approach is the term used to refer to the difference between the temperatures of the water source as it enters the tower versus the temperature of the water once it has left the tower. This is a crucial determiner of the effective of the heat exchange process.

To choose the right cooling tower, mechanical efficiency should be given priority. This refers to the amount of fan power needed to circulate ambient air within the cooling tower. The range – or the difference in temperature between hot and cold water – is also crucial as it will impact energy usage.

so to find out how to choose a cooling water tower with sufficient cooling capacity, you should understand what circumstances require the use of a cooling tower. Please find the below water cooling tower is suitable for water cooled screw chiller :

Cooling Capacity of Chiller Water Cooling Tower Capacity

5HP(16KW/4 Ton) 15 Ton

6HP(19KW/5 Ton) 15 Ton

8HP(25KW/7 Ton) 20 Ton

10HP(30KW/8 Ton) 20 Ton

12HP(40KW/11 Ton) 25 Ton

15HP(50KW/14 Ton) 25Ton

20HP(65KW/18 Ton) 30 Ton

25HP(80KW/22 Ton) 40Ton

30HP(100KW/28 Ton) 40 Ton

40HP(130KW/37 Ton) 50 Ton

60HP(200KW/56 Ton) 80 Ton

5.Which Industries Need An Industrial Water Cooled Process Chiller Unit?

Water chillers are used in various industries. Some of them include the following:

▪ Plastic manufacturing and processing

▪ Metal forming

▪ Food and beverage processing

▪ Machinery

▪ Chemical & pharmaceutical

▪ Medical (MRI, CT scanner, x-ray, linear accelerator, laboratory)

▪ Laser cutting

▪ Transportation manufacturing

▪ Semiconductor

▪ Composite manufacturing.

6.What is the Difference Between Industrial Air Cooled Process Chiller Unit and Industrial Water Cooled Process Chiller Unit?

The main difference between industrial air cooled process chiller unit and industrial water cooled process chiller unit is condenser :

The condenser of an industrial air cooled process chiller unit is cooled by the ambient air,which the heat generated during the cooling process is dissipated into the surrounding air;

Industrial water cooled process chiller unit with a shell and tube water-type condenser that is attached to a cooling tower and is typically used in medium and wide installations where water is available.So industrial Water cooled chiller need connect with water cooling tower and water cooling pump outside , the installation is more trouble than air cooled screw chiller .

But if your ambient temperature is very high above 50℃,we suggest you use industrial water cooled process chiller ,as industrial air cooled process chiller may consume more energy to achieve the same cooling capacity due to the limitations of air as a heat exchange medium and industrial water cooled chiller uses constant water source for more stable and efficient heat dissipation,so in high ambient temperature , industrial water cooled chiller is more energy-efficient and better choice for your application .

20 Ton Air Cooled Process Chiller

7.Contact Us to Learn More About Our Industrial Water Cooled Process Chiller Unit

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with an industrial water-cooled process chiller unit. Contact us today for more information on an industrial water cooled process chiller unit.

Our probessional team will help you with any questions you have on our water-cooled process chiller units. We look forward to hearing from you!