Chiller Terms

When choosing a chiller, understanding some chiller terms is crucial. In this article, we will explain some chiller terms :air cooled ,water cooled ,cooling capacity, evaporator,Energy Efficiency Ratio (EER), and Coefficient of Performance (COP). By grasping these chiller terms, you can make informed decisions to choose suitable chiller and operational efficiency.

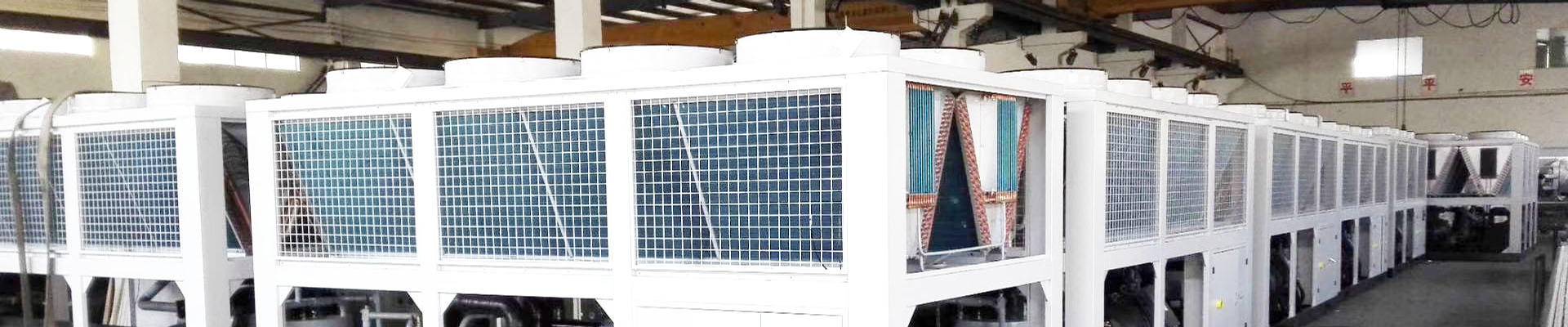

Air Cooled

"Air cooled" refers to a refrigeration system that uses ambient air to condense the refrigerant back into a liquid state, effectively cooling the system

Water Cooled

"Water cooled" refers to a chiller system that absorbs heat from process water and transfers it to a separate external water source such as a cooling tower, river, or pond. This type of chiller is often used in high-capacity applications, especially where the heat generated by air-cooled chillers can cause problems. Water-cooled chillers are preferred when cooling towers already exist or when the goal is to optimize energy consumption efficiency. However, they require regular condenser water treatment to prevent mineral buildup, which can impede heat transfer and reduce the overall efficiency of the system.

Cooling Capacity

“Cooling Capacity” in a chiller refers to the maximum cooling output the chiller is designed to provide under peak load conditions. In most chillers, the cooling capacity or capacity can usually be adjusted to closely match real-time cooling needs. This capacity is usually expressed in kilowatts (kW) or tons of refrigeration (TR) and represents the cooling power of the chiller system.

Evaporator

The "evaporator" is a key component in a refrigeration system where excess heat from the environment (such as a building) is absorbed before being delivered to the condenser. When this excess heat enters the evaporator, it causes the refrigerant inside to boil and evaporate, effectively capturing and carrying the heat to the condenser. In this process, the refrigerant enters the evaporator in the form of low-pressure liquid and leaves the evaporator in the form of low-pressure vapor, effectively absorbing and removing heat from the heat source.

Refrigerant

"Refrigerant" is a term used for any substance used to cool water in a chiller. This process takes place inside a heat exchanger or evaporator. These substances are characterized by low boiling points, including Freon and ammonia, which aid in the heat transfer process and effectively reduce the water temperature in the chiller system.

Compressor

The compressor in the refrigeration circuit compresses the cold low-pressure refrigerant gas into hot high-pressure refrigerant gas, which is then condensed into a liquid for reuse.

Chilled Water

"Chilled water" is water produced by a chiller that circulates in a closed-loop system between the chiller‘s evaporator and the cooling coils within the structure. This circulation is facilitated by pumps that drive chilled water around the building to coils in the air handling units (AHU) and fan coil units (FCU). Here, unwanted heat is transferred from the air to the water, cooling the air and heating the chilled water.

This heated chilled water is then returned to the cooler evaporator where it removes excess heat. This dispersion of heat causes the refrigerant to boil, removing heat and subsequently cooling the water again. The water then continues to circulate, collecting more heat.

Condenser(Cooling) Water

"Condenser water" refers to the water that flows between the cooling tower and the condenser in a water-cooled chiller system. It collects excess heat from the condenser, transfers it from the refrigerant, and in some designs, also absorbs heat from the compressor. The condenser water then enters the cooling tower where the captured heat is rejected to the atmosphere. After releasing the heat, the water returns to the condenser to continue the heat collection process.

Typically, the condenser water flow temperature is approximately 32°C (89.6°F) and the reflux temperature is approximately 27°C (80.6°F). However, these temperatures may fluctuate based on specific system configuration and operating conditions.

COP

“COP,” or Coefficient of Performance, critical efficiency rating for chillers. It measures the ratio of cooling or heating output to the electrical power input. For chillers, COP indicates how effectively they convert electrical energy into cooling capacity. The higher the COP, the more efficient the chiller is at providing cooling. When comparing different chiller models, prioritize those with higher COP values to optimize energy usage and minimize environmental impact. It’s a ratio representing the amount of cooling you obtain per unit of electricity input. The formula to calculate COP is:

COP = kW of Refrigeration / kW of Electricity

For instance, if a chiller provides 140 kW of cooling and uses 57.3 kW of electricity, the COP would be 2.44. This means that for every 1 kW of electricity consumed by the chiller, it generates 2.44 kW of cooling.

The COP is not constant; it fluctuates based on the cooling load on the chiller. Thus, it’s most helpful for gauging efficiency at a specific moment or under particular conditions.

EER

“EER’’ is Energy Efficiency Ratio ,maintains the instantaneous energy efficiency of chiller under specific conditions. It calculates the cooling capacity divided by the input power at a given outdoor temperature. A higher EER rating means better energy performance, making it an important consideration when evaluating industrial chillers.

Setpoint, effective chilled water setpoint

"Setpoint" in a chiller environment refers to the target temperature or pressure - most commonly, this is related to the chilled water supply temperature. This target value is set within the control range of the chiller, and the chiller aims to reach this temperature.

One component of this system is a temperature sensor located at or near the evaporator chilled water source outlet. This sensor measures the actual temperature, and the chiller‘s control uses this information to make necessary adjustments to derive the setpoint. Essentially, the goal is to get the actual temperature close to the effective chilled water setpoint.