Glycol Chiller VS Water Chiller

Time:2024-01-24

Views:205

When it comes to industrial cooling system, you most likely hear of industrial chiller.However, when you choose industrial chiller for your applications,there are two main types of chillers to consider: glycol chillers and water chillers. These two chillers have their unique advantages that can make them suitable for specific applications. In this article, we will discuss the differences between the two and examine when you need choose a glycol chiller not a water chiller.

How Does A Chiller Work?

The process works in a cycle, but we’ll start where the cooling medium interfaces with your process equipment.

The system‘s coolant absorbs thermal energy from your process, often causing a phase change to a gas. The gaseous refrigerant is then circulated to the condenser, which rejects the heat through evaporative condensation or a cooling tower. This heat exchange condenses the cooling medium into a cooler liquid, which is returned to the process heat source to start the cycle again.

What Type of Coolant Does A Chiller Use?

The type of coolant used in a chiller is based on process needs and cost considerations. The most commonly used coolants are either water or a mixture of water and another substance with suitable thermal conductivity properties, such as a glycol compound.

water

Using water as a coolant is an economical method because in most cases, water is easily available at minimal cost. Alternatively, purified water (deionized water, reverse osmosis) water can be used in water-based chillers to achieve higher cooling efficiency.

Glycol

Glycol-based coolants are composed of ethylene glycol or propylene glycol. Although these two variants have similar physical properties, they should never be mixed. The main advantage of glycol coolant is improved corrosion resistance and anti-freeze properties.

What is A Water Chiller?

A water chiller is a type of cooling system which uses water as a refrigerant to cool a process. Water chillers are commonly used in HVAC (heating, ventilation, and air conditioning) systems to cool large buildings and spaces,such as:district cooling,centralized air conditioning,hydroponics,food and beverage processing,pharmaceuticals and medical,

,machining, waterjet cutting, laser cutting, welding,and plastic processing etc.Water chillers work by circulating cool water through a loop, removing heat from the building back into the chiller, and then expelling the warm water to the cooling tower or another discharge point.

What is a Glycol Chiller?

A glycol chiller is a type of refrigeration system that uses a mixture of water and glycol to cool a process. Glycol is an antifreeze solution that is added to water to lower its freezing point and prevent the water from freezing in the chiller‘s pipes. Glycol chillers are commonly used in brewing, dairy, and other food processing industries where maintaining low temperature below 2 ℃.

Why Use a Glycol Chiller?

1. Lower Freezing Point:

As mentioned earlier, glycol is added to the water in a glycol chiller to prevent it from freezing. Glycol has a lower freezing point than water, making it an ideal solution for maintaining the chiller‘s pipes at safe temperatures. For water without impurities, the freezing point is 0°C, which is much higher than the freezing point of pure ethylene glycol, which becomes solid at -12.8°C.Especially in colder climates, where water pipes can easily freeze, glycol chillers will be necessary to avoid potential damage to the pipes.

From the above analysis, it is obvious that ethylene glycol has refrigerant properties that are more suitable for chillers working in low-temperature environments. Under these thermal conditions, the water coolant will freeze and block chiller circulation while reducing overall efficiency.

In contrast, using a glycol-based chiller will take advantage of its anti-freeze properties, ensuring the coolant remains in an ideal fluid state.

2.Low Temperature Control:

Glycol chillers are designed to maintain a low temperature below 0℃throughout the process. This is especially important for industries such as brewing, where temperature variations could drastically affect the quality of the final product. A glycol chiller can help avoid temperature fluctuations and ensure that the process maintains the desired temperature range.

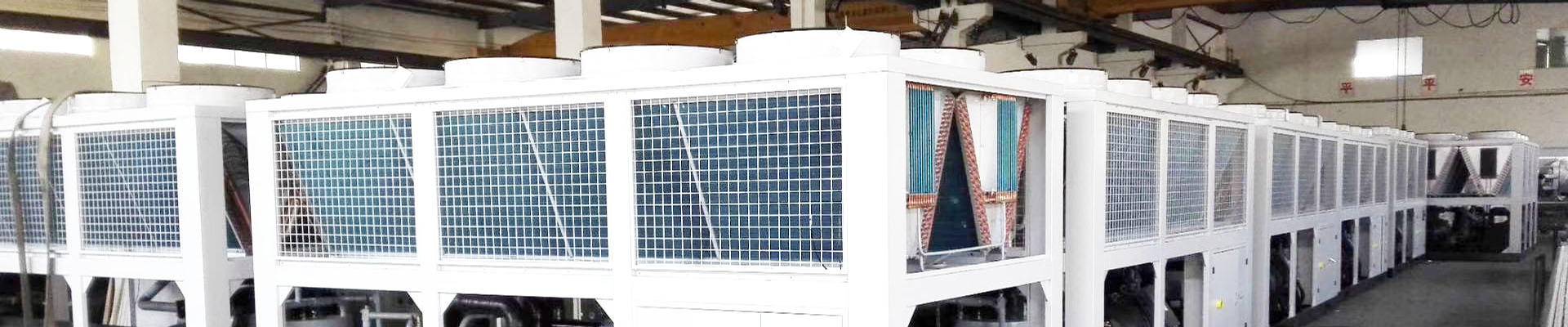

See Tongwei Chillers’ Line of Performance Chillers

For the last twenty years, Tongwei Chillers has been manufacturing premium industrial water chillers. With an impressive line of water- and air-cooled chiller units, your industrial cooling needs are sure to be met.

Contact us online today to learn more about our process cooling solutions.