How Does A Process Chiller Work ?

Time:2023-10-30

Views:138

A process chiller is a refrigeration device that removes heat generated by a given process. This cooling equipment repeatedly conducts chilled water through a closed-loop to allow a drop in rising process temperatures. The heated water is then circulated through a chiller unit and undergoes a continuous cycle of refrigeration/absorption while removing heat from the associated process. Compressing a liquid from its vaporized form during this cycle will compound the cooling effect.

Process chillers are used for products that require specific cooling temperatures to ensure the quality of the product. They are commonly used in brewing, dairy, industrial, medical ,plastic industry and other applications help ensure your equipment stays cool during processing. How do they do it? A chiller works by delivering a continuous flow of refrigerant to the cold side of the evaporator at the desired temperature. The chiller then pumps the cooled fluid through the process to remove heat from the equipment and transport it back to the return side. In this article, we’ll cover more you need to know about how a process chiller works, including the basic parts of a process chiller and the various stages of the cooling process.

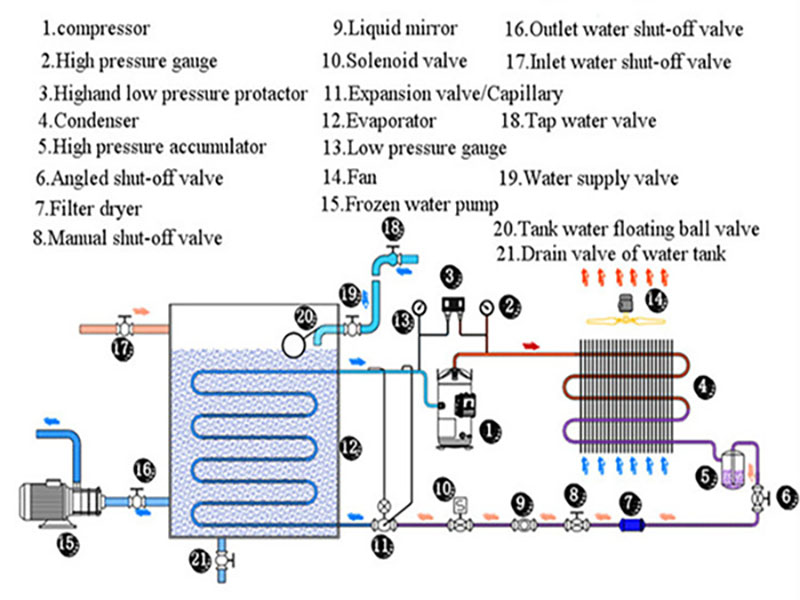

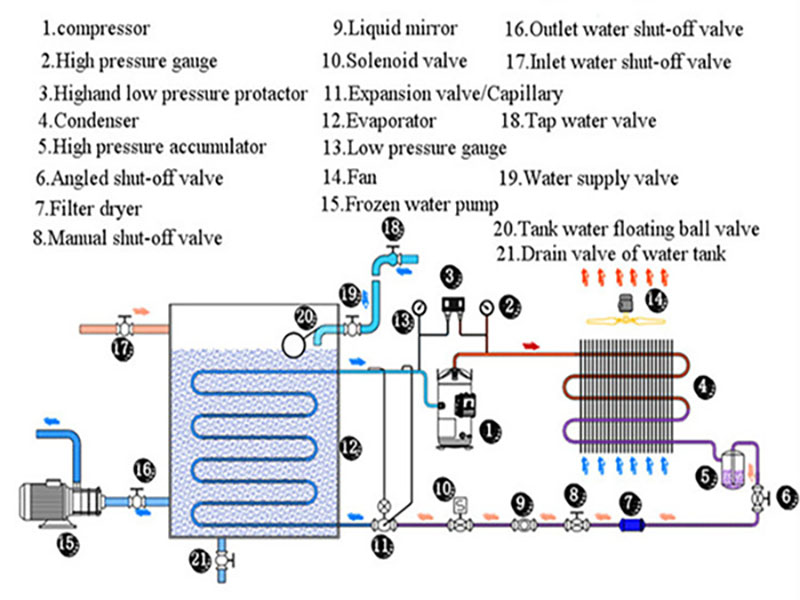

Basic components of a process chiller system

No matter which type of chiller your application requires, each model will include the following components to help keep your process cool:

Evaporator - Located between the expansion valve and the suction line connected to the compressor, the brazed plate or barrel-sized evaporator serves as the central hub from which the refrigeration cycle begins.

Compressor - The function of the chiller compressor is to compress the low-pressure gas from the evaporator and convert it into high-pressure gas before entering the condenser.

Condenser - Located between the compressor and expansion valve, the chiller condenser is available in air-cooled or water-cooled options and can be configured as a split arrangement. Read more about the differences between air-cooled and water-cooled chillers on our blog.

Expansion Valve - Electronic Expansion Valve (EEV) uses a stepper motor which helps in precise adjustment of the valve‘s position for tight super-heat control.

Stages of the chiller cooling process

Refrigerator evaporator, compressor, condenser, and expansion device all undergo a thermal process during the cooling process. The following four stages summarize how a chiller gets its job done:

Stage 1 - First, the chiller evaporator acts as a heat exchanger, where it collects and carries process heat to the cooling liquid refrigerant within the chiller. The process heat then boils the refrigerant, converting it from a low-pressure liquid to a low-pressure gas. At the same time, the temperature of the process coolant decreases.

Stage 2 – Next, the low-pressure gas enters the compressor, whose main job is to increase the pressure of the outgoing refrigerant vapor so that it reaches a high enough temperature to release heat in the condenser.

Stage 3 - Inside the condenser, the refrigerant vapor returns as a liquid. Heat is removed during the conversion of ambient air or condenser water from vapor to liquid, depending on whether you have an air-cooled or water-cooled chiller.

Stage 4 - The final stage of the cooling process involves the liquid refrigerant reaching the expansion valve, being metered before entering the evaporator, and repeating the cooling cycle again.

What features of process chillers do you look for?

When you look for a process chiller you need ,you need pay attention to the following key features that will help ensure you get optimal functionality and performance:

• Industrial strength performance

• Thermostatic control

• Run all year round

• Modulation ability

• Customizable controls

• 1% Failure rate

• Energy efficiency

• Reliability