Which Industrial Process Chiller is Right for Your Manufacturing Application?

Time:2023-10-30

Views:111

Selecting an industrial process chiller for your manufacturing application is a critical operational decision with the ability to increase your productivity, efficiency and profits. So, when choosing chiller sizes, types, and configurations is depend on your application, budget, and requirements, how do you know which one is best for you? This article will help clarify what to look for when choosing the right process chiller and introduce you to our most recommended process chiller systems.

But first, let’s start with an example of a manufacturing application that can benefit from an industrial-grade chiller and explain the differences between the various systems.

Manufacturing Application

Almost any manufacturing operation can benefit from an industrial-grade chiller. These high-performance systems are designed to keep your machine cool, even during excessive heat production. Cooling process equipment increases uptime, improves efficiency and productivity.

Here are a few manufacturing applications where industrial-grade chillers can maximize operational performance:

• Injection molding and other plastic processing

• Injection molding and other plastic processing

• Metal surface treatment

• Farming

• Laser cutting

• Machine tools and die cutting

Differences Between Various Types of Chillers

When determining the ideal chiller for your manufacturing application, it helps to understand the different types. Below, let’s take a look at what you need to know about air-cooled chillers, water-cooled chillers, and various compressor types.

Air-cooled chillers VS. water-cooled chillers

The difference between air-cooled and water-cooled chillers is how they cool the refrigerant. Air-cooled chillers use ambient air to remove heat from the manufacturing process, while water-cooled chillers use water from an external cooling tower to remove heat from the condenser.

Here are some basic benefits and considerations to keep in mind:

• Air-cooled chillers are cost-effective, energy-efficient, easy installation and space-saving, but can be noisy and may not last as long as water-cooled systems because they are exposed to the outside elements.

• Water-cooled chillers are quiet, long-lasting, and energy efficient, it can work in very high ambient temperature above 50℃ but need water cooling tower and require continuous water supply and installation is a bit tricky.

• Split system air-cooled chillers are another option for manufacturing applications that cannot accommodate traditional air-cooled or water-cooled systems. Check out our What Are Split System Coolers post for more on these uniquely engineered units.

Next, let’s talk about the various types of compressors.

Scroll Compressor VS Screw Compressor

Industrial process chillers for manufacturing applications feature scroll or screw compressors in a range of horsepower(HP), depending on your application requirements.

• Scroll Compressor - A scroll compressor has a set of interlocking scrolls that pressurize the chiller refrigerant inside the compressor. They are ideal for small or single manufacturing equipment applications with run times of less than 24 hours which need 1/2HP to 60HP chiller.

.jpg)

Air Cooled Scroll Chiller Water cooled Scroll Chiller

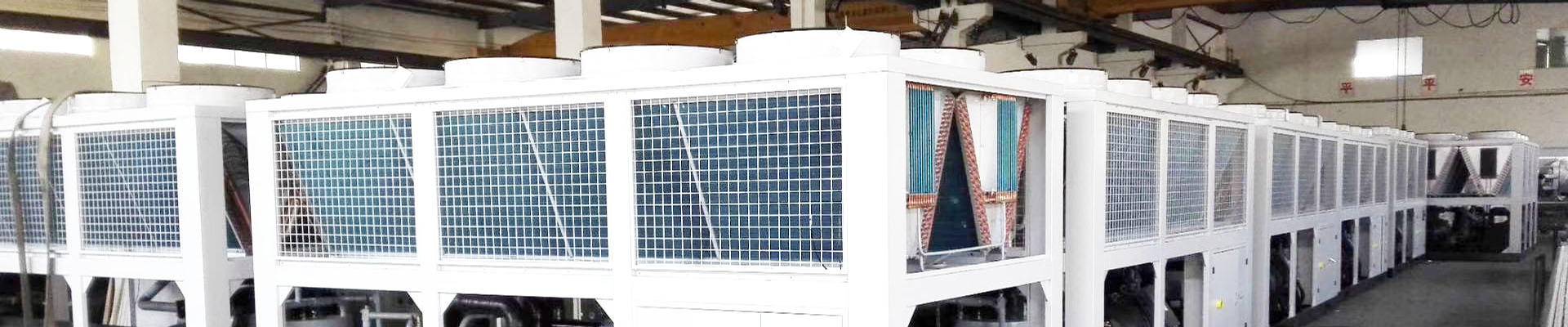

• Screw Compressor - A screw compressor increases the pressure of the gas during the cooling process and delivers it throughout the chiller system. They are ideal for large manufacturing applications requiring above 30 HP Chiller .

Air Cooled Screw Chiller Water Cooles Screw Chiller

Factors to consider when choosing the right chiller

Regardless of your manufacturing application, consider these four factors to choose your ideal chiller:

1.Cooling Capacity - The cooling capacity requirements for manufacturing applications are a core determinant of the perfect chiller. For example, if your manufacturing application requires low temperatures, a low temperature glycol chiller may be the best solution for you.

2.Control - If you are looking for tight process control, consider customizing your industrial chiller with an microprocessor ,PLC controller and other high-tech features for remote access, alarm alerts and performance monitoring.

3.Energy Efficiency - If energy efficiency is important to you, consider equipping your industrial chiller with energy-saving options to save on energy costs and conserve resources. These options include electronically commutated (EC) condenser fans, heat recovery, variable frequency drives (VFD), digital scroll compressors and compressor uploads.

4.Cost - budget is a major consideration for most manufacturers when investing in industrial process chillers. Work with a chiller supplier who can customize your system to provide only the features you need, preventing you from upgrading to a more expensive model.

Cooling capacity, control, energy efficiency and cost are just a few factors to consider in determining which industrial chiller is right for you. Contact our team and let us guide you through the system selection process, guided by your application needs.