How To Sizing A Best Chiller Unit For Your Application

Time:2023-10-30

Views:154

No matter what industry you‘re in, or what kind of chiller system you need, making sure you have adequate cooling is key to optimal performance. While it may not seem like there is much to consider when purchasing a size chiller and type of chiller machine, there are some variables that should be taken into consideration.

The first step is to calculate the total cooling requirements of the plant. This should take into account the heat generated by the process itself, but do not overlook other areas in the plant that may require cooling such as hydraulic systems, ambient operating temperatures (cooling losses), etc.

Once all of this information has been compiled, it‘s time to start evaluating which type of equipment will be the best for the application and will work best in your facility. The most important criteria to consider are total cooling load, upfront cost, floor space, noise, total operating costs, processing performance, cooling equipment environment, and maintenance and reliability.

The first decision is usually whether it makes more sense to have a dedicated chiller for each machine or whether a plant-wide system makes more sense. The second decision is choosing an air-cooled or water-cooled chiller is the right choice. Let‘s look at each of the different options.

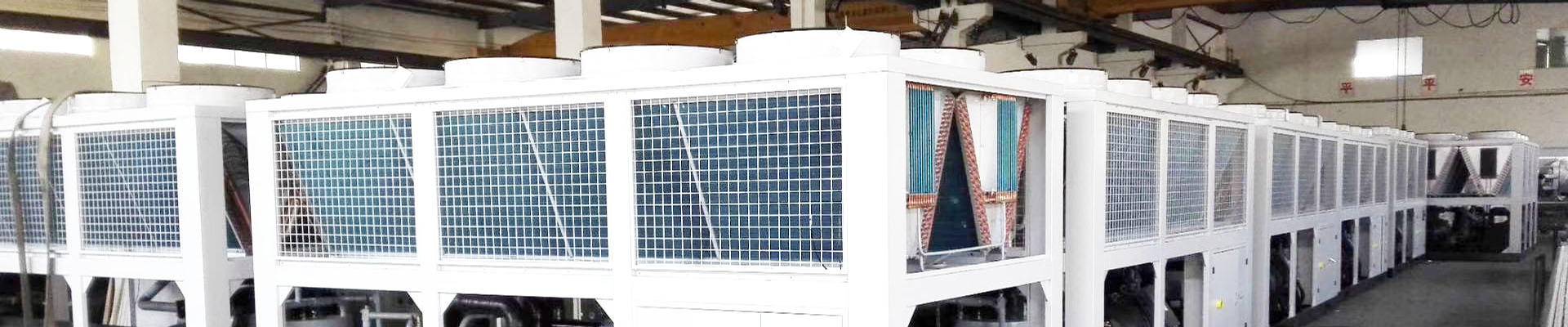

Total cooling capacity ------if the total cooling capacity is 20 tons or more, and there are at least three machines that need to be cooled, and all machines use the same temperature of water and are on the same production line, we suggest to use a central chiller . Otherwise, a portable water chiller would be the right choice.

Initial cost----Portable chillers is more expensive than central chillers in cost per ton. However, purchasing a portable water chiller allows you to purchase only what you need for your current use. If your plans change in the future, you‘re not spending money on cooling capacity you no longer need or buying cooling equipment that doesn‘t meet your requirements.

Installation costs vary widely based on the specific plant layout, the type of equipment selected, the amount of work done in-house, and how the portable chiller is installed.

A centralized system will cost more to install, and it will require a team of professional workers to complete the installation. Portable chiller installation is easier and can be done by in-house maintenance personnel as all that is required is to install hoses and pipes between the chiller and the process, connect power to the chiller, and fill it with water or a water/glycol mixture . Then press the "Run" button.

Floor space----- In most factories, floor space is at a premium. Portable chillers are located close to the process on the production floor, taking up valuable space that could be used for other equipment or more primary equipment. In contrast, a central chiller can be located in the machine room or outdoors.

Noise level----Depending on whether an air-cooled or water-cooled portable chiller is used, the noise level from the machine can be quite high, disturbing the operator. Removing cooling equipment from the production floor significantly reduces noise. If you want low noise ,we suggest you choose water cooled chiller , then water cooling tower connected with chiller installed outdoor.

Operating Cost.-----Portable chillers must be selected for the largest considered cooling requirement that the machine it is cooling might require. Central chillers have different methods of providing less capacity at a reduced energy cost, making them more efficient at reduced loads. It is outstanding to see a central chiller with a screw or scroll compressor save 30 percent in energy vs. individual portables.

Maintenance Considerations-----Downtime is always a concern. With individual portables, if one fails, then that machine is down, unless a spare portable is available. However ,if you choose central chiller system, when it is with problems ,all your machine need stop for work .Regardless of which type of chiller you have, preventive maintenance should be done at a minimum of every six months. Consider the actual cost of your downtime and consider that cost when making an upfront purchase. We suggest you choose portable chiller .

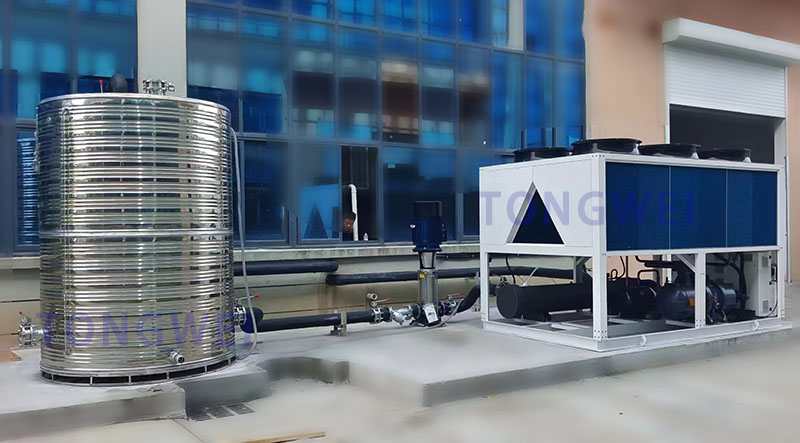

Whether you purchase a portable chiller or a central chiller, you need determine to choose an air-cooled condenser or a water-cooled condenser. Water-cooled chillers require a secondary cooling source, usually a cooling tower, to provide 85°F (29°C) water to the chiller. If there are many other places in the plant that can accept 85°F (29°C) water, it makes sense to install a cooling tower system. If not, it is usually not cost-effective to put a cooling tower just to provide cooling for the condenser of the chiller.

It is important to realize that if an air-cooled chiller is located in a factory, it will take in factory air and exhaust significantly hotter air. While this is beneficial during the winter, it‘s definitely a disadvantage if your plants are air-conditioned. In this case, you either want to place the chillers outside of the conditioned area or possibly outside the building.

One final consideration need to note when sizing a chiller - air-cooled chiller is to realize that if your operation generates a fair amount of dust, it will be necessary to clean the chiller‘s condenser more frequently to avoid any impact on performance. Negative impact. If your working environment temperature is higher than 45℃, the cooling efficiency of the air-cooled chiller will be greater affected. Of course, if there is a shortage of water in your area, then the water-cooled chiller is not a good choice because It requires a lot of water.

When sizing your chiller, it is highly recommended that you consult with your refrigeration equipment manufacturer who has technicians available to evaluate your individual application and assist in sizing your chiller system for optimal cooling performance