| Content 4.1 Compressor

4.2 Evaporator

4.3 Oil Pump

4.4 Condenser

4.5 Controller Panel

|

1.What is Oil Chiller Unit?

3.What Are Types Of Oil Chillers Unit?

Immersion oil chiller unit is no built with oil pump and oil tank , it use Stainless steel coil as heat exchange.

Box Type Oil Chiller Unit Immersion Oil Chiller Unit

Features and Advantages of Oil Chiller Unit:

▪ Prevent mechanical spindly work due to the temperature rise and affect accuracy;

▪ Maintain the stability of the processing solution ,and improve the precision and efficiency;

▪ Stable hydraulic and provent oil shock;

▪ Easy operation low noise;corrosion preventing tube obstruction;

4.What Are The Main Components of Box Typ Oil Chiller Unit?

Panasonic Compressor

SS Plste + Oil Tank Evaporator

4.3 Oil Pump

The oil pump is designed to increase the pressure and the flow of the chilled oil in a closed space.

Oil Pump

4.4 Condenser

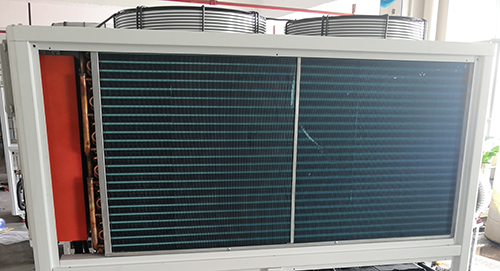

The condenser for oil chiller unitis equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser

4.5 Controller Panel

Tongwei chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

6.Contact Us to Learn More About Our Oil Chillers Unit

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with oil chillers unit. Contact us today for more information on a oil chiller unit.

Our probessional team will help you with any questions you have on our oil chiller units. We look forward to hearing from you!