|

Content

3.1 Compressor

3.2 Evaporator

3.3 Water Pump

3.4 Condenser

3.5 Controller Panel

|

1.Low Temperature Glycol Chillers On The Application

Water Cooled Glycol Chiller

3.What Are The Main Components of Water Cooled Glycol Scroll Chiller?

3.1 Compressor

The compressor is the key mover in packaged Water Cooled Chiller because it produces pressure variations to stir the refrigerant around.

For 15 Ton chiller , which is with two units Panasonic brand compressor, using R404a refrigerant,this brand compress is with high refrigeration efficiency,low noise ,energy saving,environmental protection and durability,safety and stability.

Panasonic Compressor

Danfoss Compressor

3.2 Evaporator

The evaporator is a crucial component of packaged water cooled glycol chiller, as it is responsible for extracting heat from the liquid being cooled,it is located between the compressor and the expansion valve. There are three types of evaporators : shell and tube evaporator, 304SS stainless steel plate type evaporator.

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

Shell and Tube Evaporator

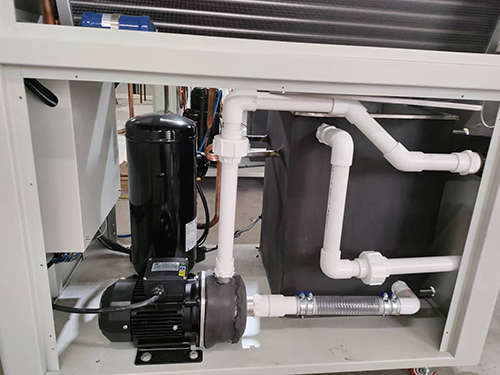

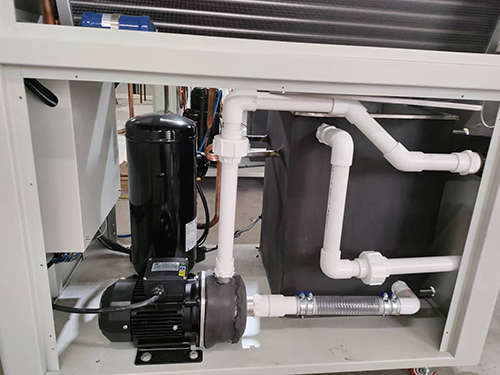

3.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

the water pressure water pump for chiller is about 2 bar , but if you need more higher water pressure , pls tell us when you inquiry .

Water Pump

High Pressure Water Pump

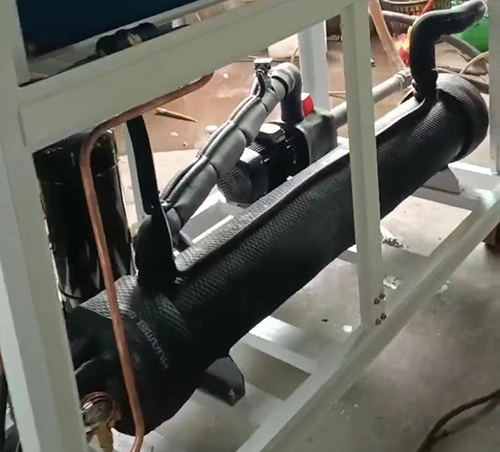

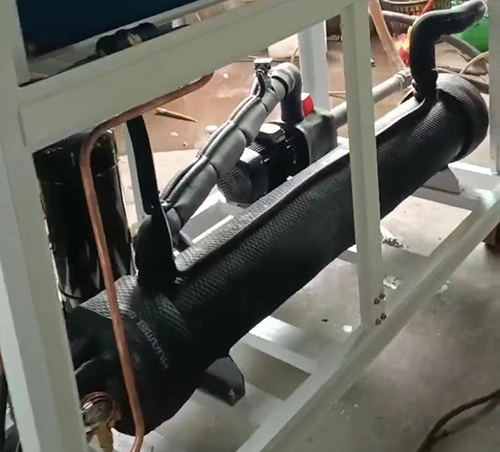

3.4 Condenser

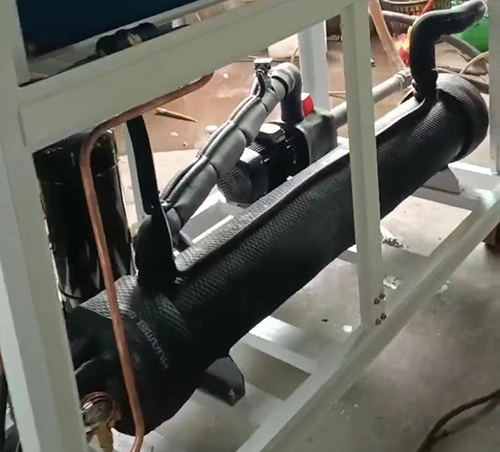

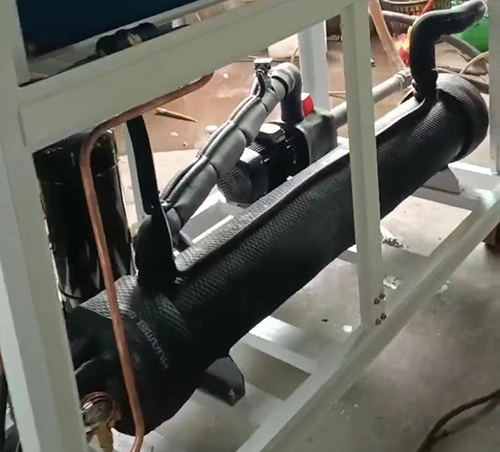

The condenser for packaged water cooled glycol chiller is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser

3.5 Controller Panel

Tongwei chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

4.What is the Difference Between Water Cooled Glycol Scroll Chiller and Water Cooled Glycol Screw Chiller?

Water Cooled Glycol Scroll Chiller Water Cooled Glycol Screw Chiller

▪ 3hp-60HP Above 60HP

▪ Danfoss/Panasonic Scroll Compressor Hanbell/Bitzer Screw compressor

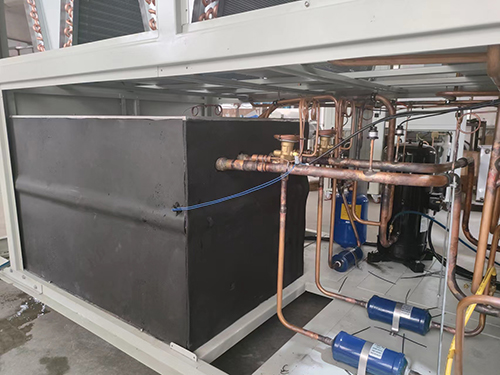

▪Built with water tank and water pump Without water tank and water pump

Panasonic Compressor

Danfoss Compressor

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

Shell and Tube Evaporator

3.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

the water pressure water pump for chiller is about 2 bar , but if you need more higher water pressure , pls tell us when you inquiry .

Water Pump

High Pressure Water Pump

3.4 Condenser

The condenser for packaged water cooled glycol chiller is shell and tube ,with the internal copper tubes employing an outer thread embossing process.This design effectively enhances the heat exchange efficiency between the refrigerant and water during the process. Compared to traditional smooth copper tubes, the outer thread embossing process increases the surface area of the copper tubes, thereby expanding the contact area for heat exchange and improving the thermal conductivity of the condenser. This optimization design allows the condenser of the water-cooled chiller to transfer heat from the refrigerant to the water more rapidly and consistently, enabling the water to carry away the heat.

Shell and tube Condenser

3.5 Controller Panel

Tongwei chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

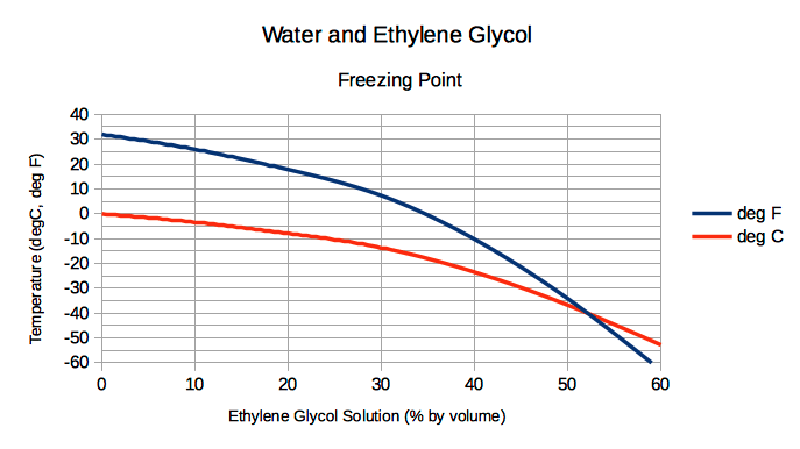

Comparison of Ethylene Glycol and Propylene Glycol

targets the kidneys

Glycol Water Water Temperature

Glycol Chiller for Cider Mills

Glycol Chiller for Distilleries

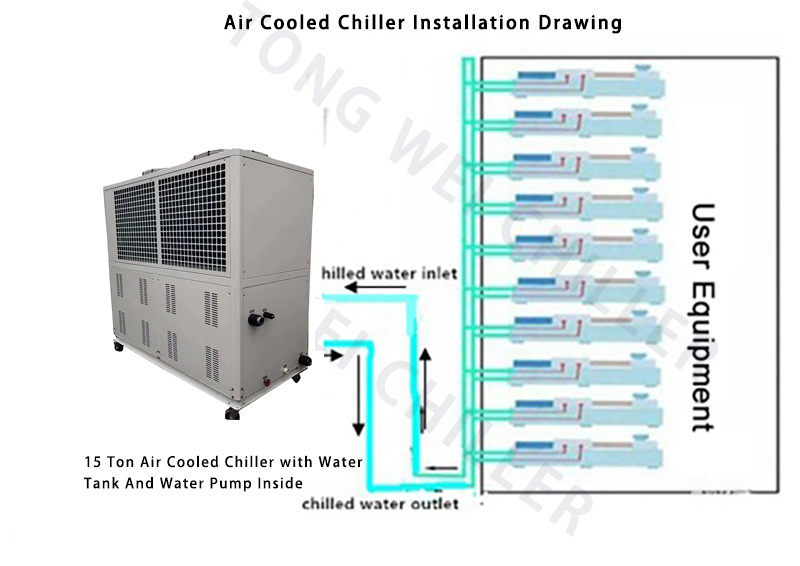

Air-cooled Scroll Glycol Chiller Installation for Reference

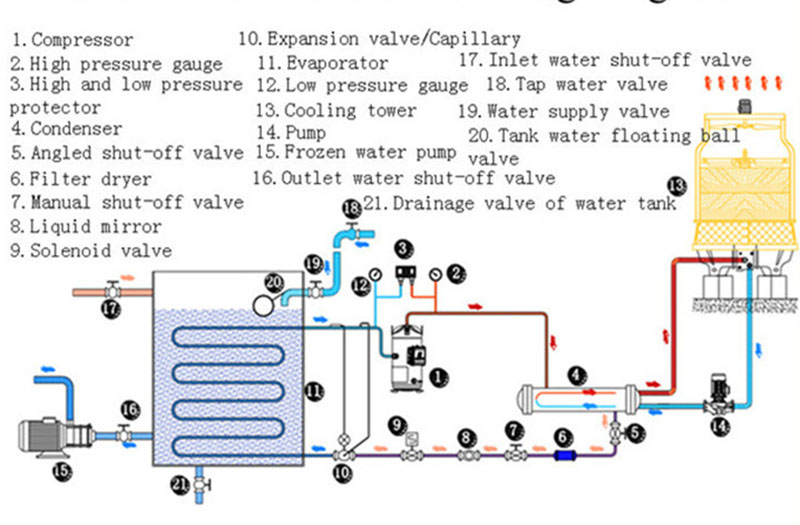

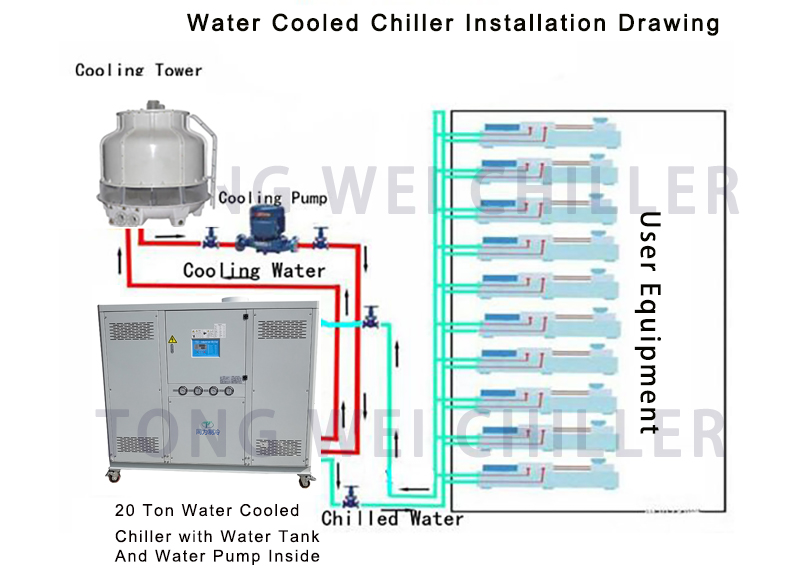

Water-cooled Scroll Glycol Chiller Installation for Reference

10.Contact Us to Learn More About Our Low Temperature Glycol Chiller

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with a low temperature glycol chiller. Contact us today for more information on a chiller.

Our probessional team will help you with any questions you have on our chiller units. We look forward to hearing from you!