Overload Protection

High and Low Pressure Alarm

Water Level Indicator

Inverse Phase Alarm

Water Flow

Anti-Freeze Protection

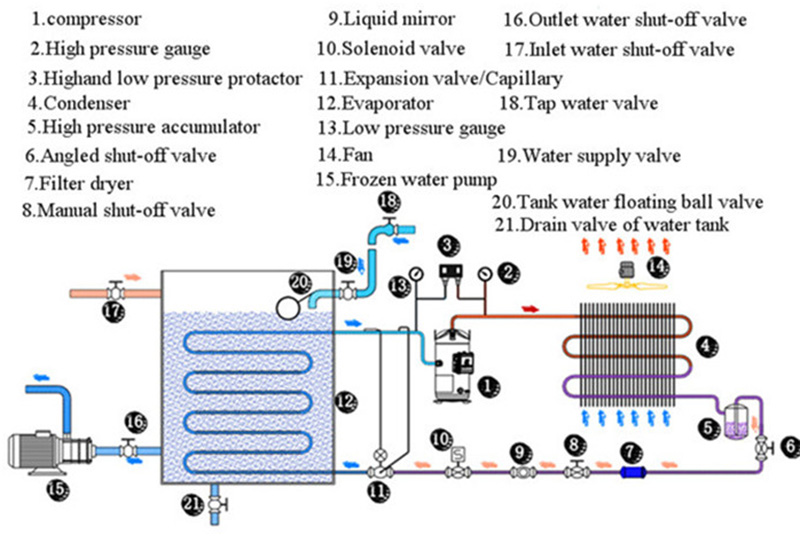

2.What Are The Main Components of Portable Industrial Glycol Chiller ?

2.1 Compressor

Panasonic Compressor

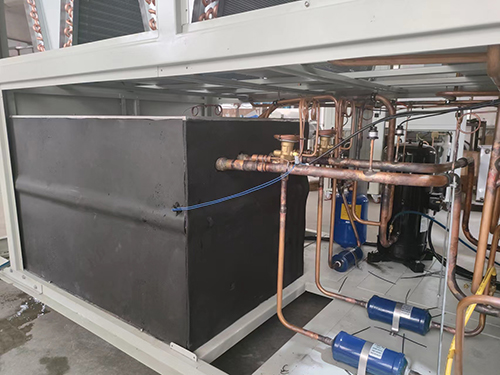

SS Plate Type+ Water Tank Evaporator

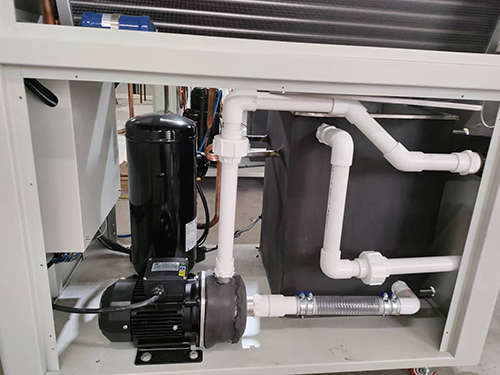

2.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

the water pressure water pump for chiller is about 2 bar , but if you need more higher water pressure , pls tell us when you inquiry .For example ,when you use chillers for cooling bottle blowing machine ,the water pressure for water pump need about 4 bar .

Water Pump

High Pressure Water Pump

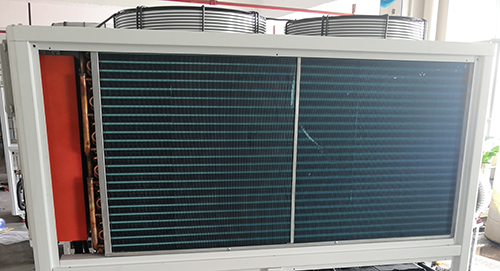

2.4 Condenser

The condenser for portable air cooled glycol chiller is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser

2.5 Controller Panel

Tongwei chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

3.What Types of Portable Industrial Glycol Chiller?

There are two types of portable industrial glycol chiller : Portable industrial air cooled glycol chiller and Portable industrial water cooled glycol chiller.

Comparison of Ethylene Glycol and Propylene Glycol

targets the kidneys

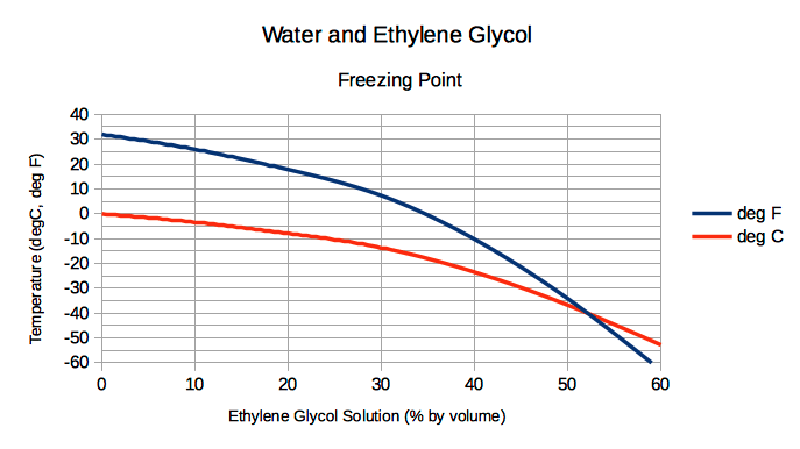

Glycol Water Water Temperature

Glycol Chiller for Cider Mills

Glycol Chiller for Distilleries

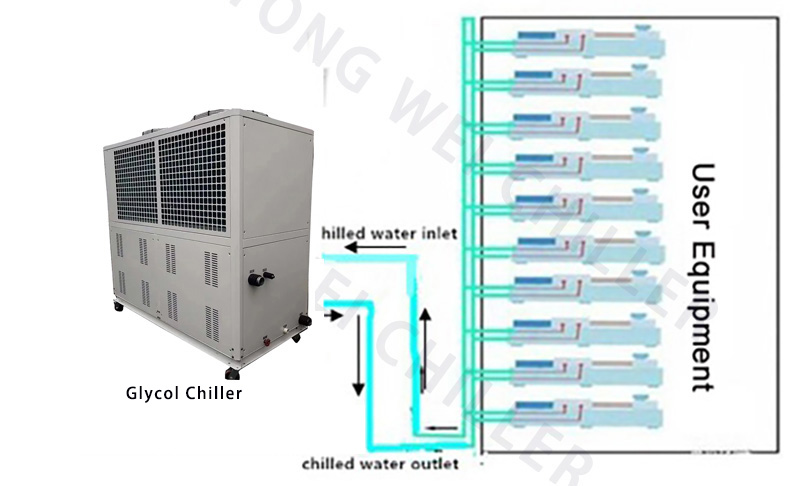

Portable Industrial Air-cooled Glycol Chiller Installation for Reference

Portable Industrial Water-cooled Glycol Chiller Installation for Reference

9.Tips For Portable Industrial Glycol Chiller Maintenance

Inhibited Glycol

Inhibited glycol has ingredients that protect against corrosion, scale, and rust, which is not present in uninhibited glycol. Glycol must be used at 25% combinations or higher to have sufficient amounts of the inhibitors present in the mixture.

Mixing Ethylene and Propylene Glycol

All manufacturers will tell you never to mix ethylene and propylene glycol or different brands of glycol. The incompatibility between the various formulas can lead to clogged filters, strainers, pumps, and problems with transfer properties.

Local Regulations

States, counties, and cities have different regulations regarding the use of glycol and antifreeze to protect water tables, drainage, and disposal of fluids. Before installing a glycol chiller, it is important to contact local authorities to ensure compliance with municipal regulations.

Contamination

The ratio of glycol to water has to be continually checked and tested to ensure that the percentages are being maintained and corrosion issues are not present.

Pure Water

Glycol chillers work best if distilled or reverse osmosis purified water is used since city water has contaminants that can inhibit combining glycol with the water. Other forms of pure water include demineralized water, which removes the unpredictability of city and municipal water.

10.Contact Us to Learn More About Our Portable Industrial Glycol Chiller

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with portable industrial glycol chiller. Contact us today for more information on a chiller.Our probessional team will help you with any questions you have on our chiller units. We look forward to hearing from you!