Industrial Chillers for Industrial Processes And Applications

Air-cooled Chiller Features

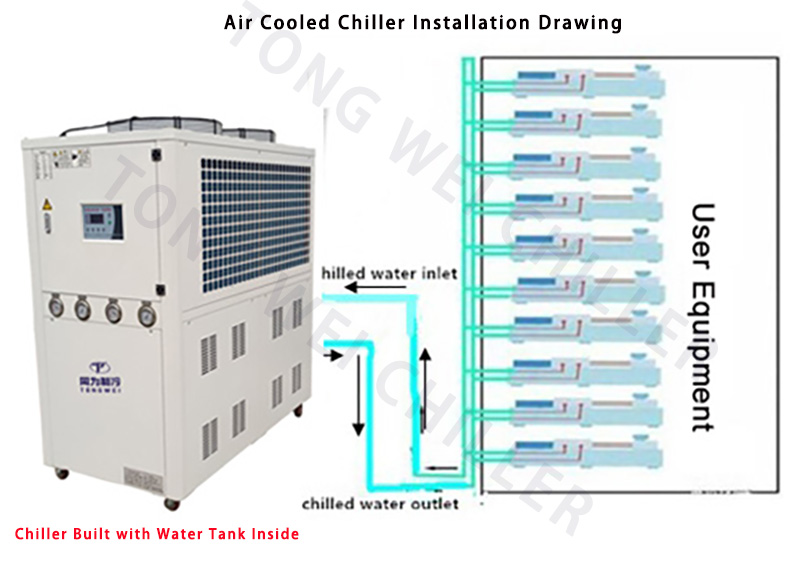

Industrial Air Cooled Chiller Industrial Water Cooled Chiller

2.What are the differences between industrial air cooled chiller and water cooled chiller ?

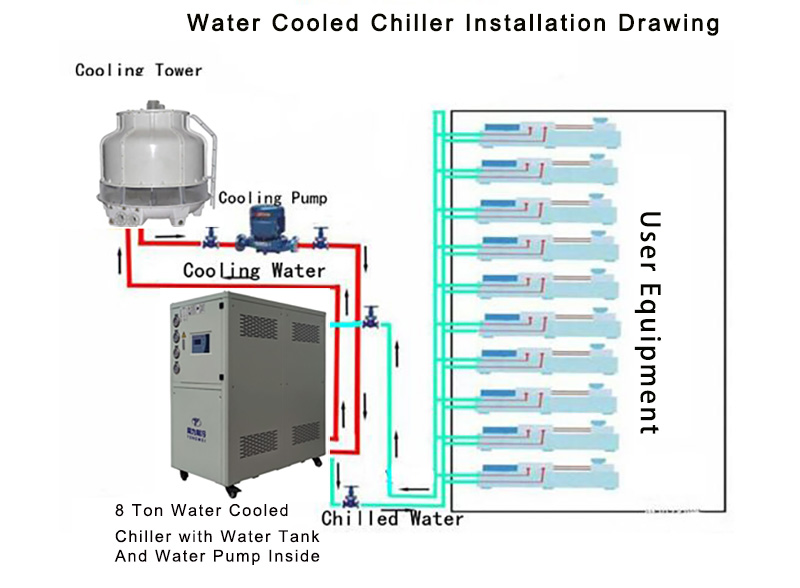

▷ Industrial water cooled chillers use shell and tube as condensers.The heat enters the condenser water from the refrigerant vapor. The warm condenser water is then pumped to the water cooling tower, where the heat from the process is eventually vented to the atmosphere.

So the main difference between industrial air cooled chiller and water cooled chiller is that :

Industrial Water Cooled Chiller Installation

3.What Are The Main Components of Industrial Chiller?

Panasonic Compressor

Coil in SS Water Tank Evaporator

SS Plate Type+ Water Tank Evaporator

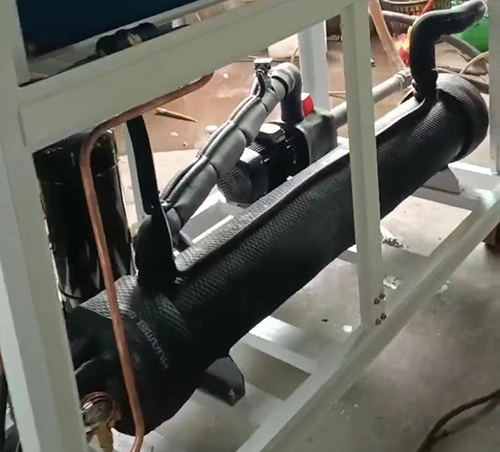

Shell and Tube Evaporator

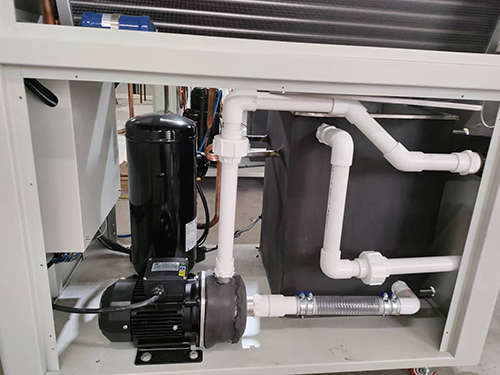

3.3 Water Pump

The water pump is designed to increase the pressure and the flow of the chilled water in a closed space.

the water pressure water pump for chiller is about 2 bar , but if you need more higher water pressure , pls tell us when you inquiry .For example ,when you use chillers for cooling bottle blowing machine ,the water pressure for water pump need about 4 bar .

Water Pump

High Pressure Water Pump

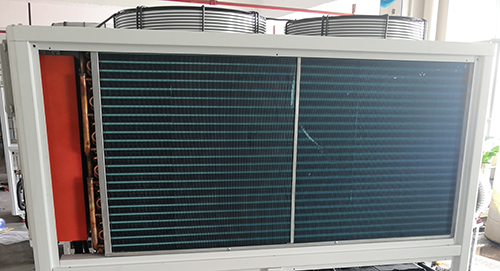

3.4 Condenser

The condenser for industrial chiller is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser

3.5 Controller Panel

Tongwei chillers use precision digital temperature controller, it RS485 communication port,which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Controller Panel

4.What Applications of Industrial Chiller System Used In?

Industrial chillers are very popular refrigeration system that can provide steady and reliable water cooling sources for both industrial and commercial usage.

Below are some of the most common applications:

4.1 Plastic Industry

Indsurial chillers are also widely used in plastic processing and plastic industry including plastic injection molding, plastic extruders, and extrusion lines, blowing molding machines.

The function of using an industrial chiller system is to provide the cooling water flow rate for cooling the plastic mold temperature down to make sure the product quality and production efficiency.

Stationary water Cooled Chiller For Plastic Industry

4.2 Food Industry

Indsutrial chiller are important in the food industry to maintain temperature control, preserve quality, support various production processes, and comply with regulations.

For instance, winery chillers are used for temperature control during the fermentation and storage of wine. Likewise, bakery chillers help with mixer cooling, potable water cooling, and cooling jacketed tanks of yeast which are all critical bakery components.

Stationery Water Cooled Chiller For Food Industry

4.3 Metal Finishing

In metal finishing processes such as electroplating or electroless plating, temperature control is essential to remove excess heat, as they often require very high temperatures (hundreds of degrees) to bond the metal. Some industries use metal finishing chillers to cool the anodizing fluid in heat exchangers or use glycol/water as the cooling medium to reduce the temperature inside the water tank.

Metal Finish Process

5.Why Tongwei Chiller Can Be Your Trustworthy Industrial Chillers Supplier

15 Years Experience

With immediate reductions in water usage and consistent cooling water temperatures, chillers provide a dramatically improved process and a quick return on investment.

Over the years we have gained expertise in chiller industry....not only when used with welders, but also in many other industrial applications. As word spread, we stocked up on chillers, and we began selling to other industries that needed to control cold water. Today, we sell chillers for a variety of applications in the United States, Canada, Mexico, and even around the world.

Our industrial chillers are top-notch and we provide exceptional customer service. There are many cheap chillers on the market, but the brands we carry represent excellent value over the long term.

High Quality Products

All our chiller is made with original accessories,all chiller spare parts are strictly inspected. These inspections include supplier audits, ingredient testing, quality surveillance, stress testing and sample testing. All inspection and quality control systems will ensure that your chiller is at a high quality level from the beginning of production.

During the chiller production, we pay more attention to the whole process control. Each process is carried out according to operation instructions, such as welding workmanship inspection. All these quality control systems ensure all chiller order is 100% running well.

When the chiller is finish production ,we will test the chiller and adjust parameter for chilers .

After testing, all the indicators of your chillers can meet our standards. It was said that all inspections are qualified and allow to release. We will package and arrange delivery of your ordered product to your place.

Free Consult & Calculation

We need you give us information about demand when you inquiry ,our engineers will study your cooling demand and free offer you the correct chiller.

Long Warranty Period

We have 24 months warranty time covered all our chiller products depending on your detailed chiller requirements.

During this time, we will provide free technical support and chiller spare parts to solve your chiller problem.No fear of any trouble in the rear.

If you are satisfied with our chiller performance and need more chillers to extend your business, please contact our sales representatives to re-order.

6 .How I Can Choose The Right Industrial Chiller?

There are four important chiller specifications you need consider when you choose a chiller for your application :the voltage required for operation, the associated pump horsepower and flow rate (contact us for custom selection), refrigerant, and the evaporator type.

6.1 Power

Different countries and regions have different standards for industrial electricity, the common power supplies are 208-230V, 380-420V,440-480V,50Hz or 60Hz, 3phase.

Such in Philippines ,the power supply is 220V 60HZ 3PH , 380V 60HZ 3PH ,460V 60HZ 3PH;

in Singapore and Malaysia ,the power supply is 415V 50HZ 3PH;

in Mexico ,the power supply is 220V 60HZ 3PH;

In USA ,the power supply is 208V 60HZ 3PH;575V 60HZ 3PH;480V 60HZ 3PH and so on

6.2 Water Pump

When you decide the capacity/tonnage of the chiller, we will recommend you the suitable pump in KW,which standard water pump is about 2 bar .If you need more high water pressure , please us when you inquiry.

6.3 Refrigerant

R22, R410A, R407C, R404A, R134A are optional choices.

R22: good cooling effect, but R22 is considered a powerful greenhouse gas, so it’s forbidden in most countries.

R410A: eco-friendly, R-410A has replaced R-22 as the preferred refrigerant for use in residential and commercial air conditioners in Japan, Europe, and the United States. R-410A operates at higher pressures than other refrigerants.

R407C: a good replacement for R22, good cooling effect.

R404A: suitable for application that requires low temperature(below -10°c).

R134A: a non-flammable gas used primarily as a “high-temperature” refrigerant, suitable for air-cooled chiller working at a high ambient temperature above 50℃.

6.4 Evaporator Choose

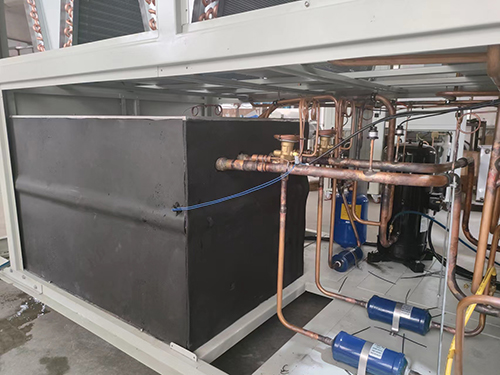

Chillers generally have two types of evaporators: one is coil in water tank evaporator ,the other one is shell and tube evaporator.

Coil and tank evaporator, which has a built-in water storage tank for more convenient use,so there’s no need for extra buffer tanks. This is also our standard evaporator for chiller , if you don’t have buffer tank ,we just use this evaporator for your chiller.(See Above 2.2)

Shell and tube type evaporator, which requires an additional water buffer tank to connect .(See Above 2.2)

7.Contact Us to Learn More About Our Industrial Chiller System

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with an industrial scroll chiller. Contact us today for more information on a chiller.

Our probessional team will help you with any questions you have on our industrial air cooled scroll chiller units. We look forward to hearing from you!