|

Content ▷1.Stationary Air Cooled Chillers Vs Stationary Water Cooled Chillers ▷2.How does Stationary Air Cooled Chiller work? ▷3.What are Differences Between Stationary Chiller and Portable Chiller ? ▷4.What Are Main Components of Stationary Air Cooled Water Chiller ? 4.1 Compressor 4.2 Evaporator 4.3 Condenser 4.4 Controller Panel ▷5. How I Can Choose the Right Stationery Chiller? ▷6.Industrial Applications of Stationary Air Cooled Water Chiller ▷7.Contact Us to Learn More About Our Stationary Air Cooled Water Chiller |

Stationary air cooled water chiller capacity range is from 30kw to 1000kw, water cooling temperature is adjustable from 5 to 30 ℃,it need be piped to a pump and a separate water tank to function.The chiller can be used with one ,two ,three or four compressors(three and four compressors is scroll compressor) , and each compressor has an independent refrigeration circuit. All compressors are under the command of a unified microcomputer control system, which can be turned on and off one by one without interfering with each other. Stationary air cooled water chiller is all made of original and genuine products, single machine failure rate is very low. Considering the above reasons, the chiller can be guaranteed to have a highly stable performance.

than dry surfaces.

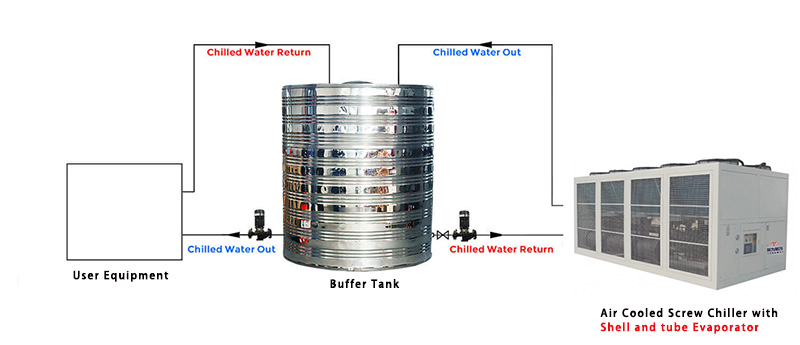

120Ton Stationary Air Cooled Water Chiller with Buffer Water Tank Outside Installation for Reference

3.What are Differences Between Stationary Chiller and Portable Chiller ?

Portable chiller combines all necessary components including – the refrigeration circuit, full diagnostic touch screen controllers and electrics, process pump ,a reservoir tank,which is easily to install.

Stationary Air-Cooled Chiller Portable Air-Cooled Chiller

For Below 50 Ton Chiller ,which use Panasonic/Danfoss scroll ompressor,using enviromental friendly R410a/R407c refrigerant;

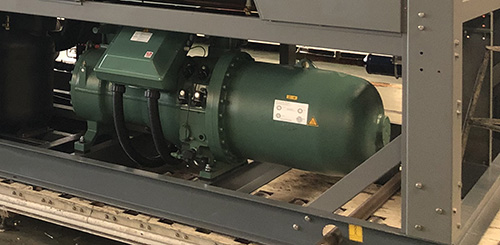

Hanbell Screw Compressor

Bizter Screw Compressor

Shell and Tube Evaporator

4.3 Condenser

The condenser for stationary air cooled water chiller is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.Its function is to cool down the refrigerant steam released from the compressor into a liquid or gas-liquid mixture.

Aluminum fin+fan Condenser

4.4 Controller Panel

Tongwei chillers use Integrated PLC control system with human-computer interface and big LED touch screen panel.

PLC Controller Panel

5. How I can Choose the Right Stationary Chiller?

There are four important chiller specifications you need consider when you choose a chiller for your application :the cooling capacity for chiller ,the voltage required for operation, the associated pump horsepower and flow rate (contact us for custom selection), refrigerant, and the evaporator type.

5.1 Calculate Right Cooling Capacity For Chiller

One of the most frequently ask about how we can know the cooling capacity for chillers. Let’s see the below formula.

5.2 Power

Different countries and regions have different standards for industrial electricity, the common power supplies are 208-230V, 380-420V,440-480V,50Hz or 60Hz, 3phase.

Such in Philippines ,the power supply is 220V 60HZ 3PH , 380V 60HZ 3PH ,460V 60HZ 3PH;

in Singapore and Malaysia ,the power supply is 415V 50HZ 3PH;

in Mexico ,the power supply is 220V 60HZ 3PH;

In USA ,the power supply is 208V 60HZ 3PH;575V 60HZ 3PH;480V 60HZ 3PH and so on

5.3 Water Pump

When you decide the capacity/tonnage of the chiller, we will recommend you the suitable pump in KW,which standard water pump is about 2 bar .If you need more high water pressure , please us when you inquiry.

5.4 Refrigerant

R22, R407C, R404A, R134A are optional choices.

R22: good cooling effect, but R22 is considered a powerful greenhouse gas, so it’s forbidden in most countries.

R407C: a good replacement for R22, good cooling effect.

R404A: suitable for application that requires low temperature(below -10°c).

R134A: a non-flammable gas used primarily as a “high-temperature” refrigerant, suitable for air-cooled chiller working at a high ambient temperature above 50℃.

5.5 Evaporator Choose

Air cooled screw chiller generally uses one evaporators: just is shell and tube heat exchanger.

Shell and tube type evaporator, which requires an additional water buffer tank to connect.

5.6 Buffer Water Tank Capacity Choose

Buffer tank’s capacity can be customized according to specific needs. It can buffer a larger heat load, store more chilled water .

304 Stainless Steel Water Tank

6.Industrial Applications of Stationary Air Cooled Water Chiller

Stationary Air-cooled water chillers are very popular refrigeration system that can provide steady and reliable water cooling sources for both industrial and commercial usage.

Stationary Air cooled water chillers are also widely used in plastic industry.food industry and Cement/ Concrete Cooling.

6.1 Plastic Industry

Air-cooled water chillers are also widely used in plastic processing and plastic industry including plastic injection molding, plastic extruders, and extrusion lines, blowing molding machines.

The function of using an air-cooled screw chiller is to provide the cooling water flow rate for cooling the plastic mold temperature down to make sure the product quality and production efficiency.

Air Cooled Screw Chiller For Plastic Industry

6.2 Food Industry

Stationary Air cooled water chiller are important in the food industry to maintain temperature control, preserve quality, support various production processes, and comply with regulations.

Air Cooled Screw Chiller For Food Industry

6.3 Cement /Concrete Cooling

Cement production involves a series of chemical reactions that generate significant amounts of heat.Cement is usually mixed with water to from the material known as concrete whose temperature is to a great extent determined by the water used in the chemical combination of cement aggregates and water.

7.Contact Us to Learn More About Our Stationary Air Cooled Water Chiller

Don’t delay in making the best decision for your manufacturing business and your future by increasing your production capabilities with an stationary air cooled water chiller. Contact us today for more information on a stationery air cooled chiller.

Our probessional team will help you with any questions you have on our stationary air-cooled chiller units. We look forward to hearing from you!